Motor permanent magnet fixing device

A fixed device and permanent magnet technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of falling off, permanent magnet movement, etc., to facilitate processing, prevent movement, and save permanent magnet materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

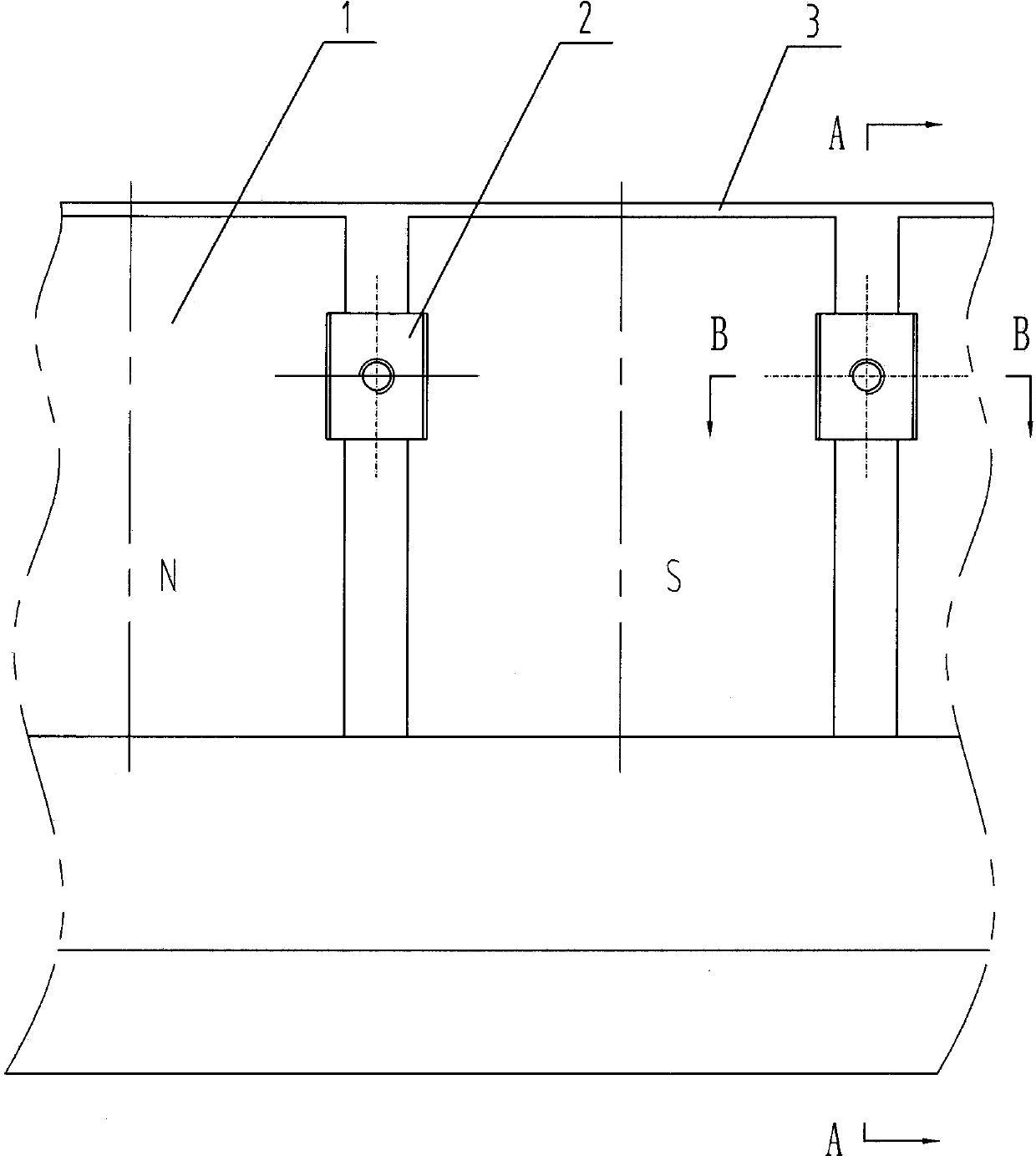

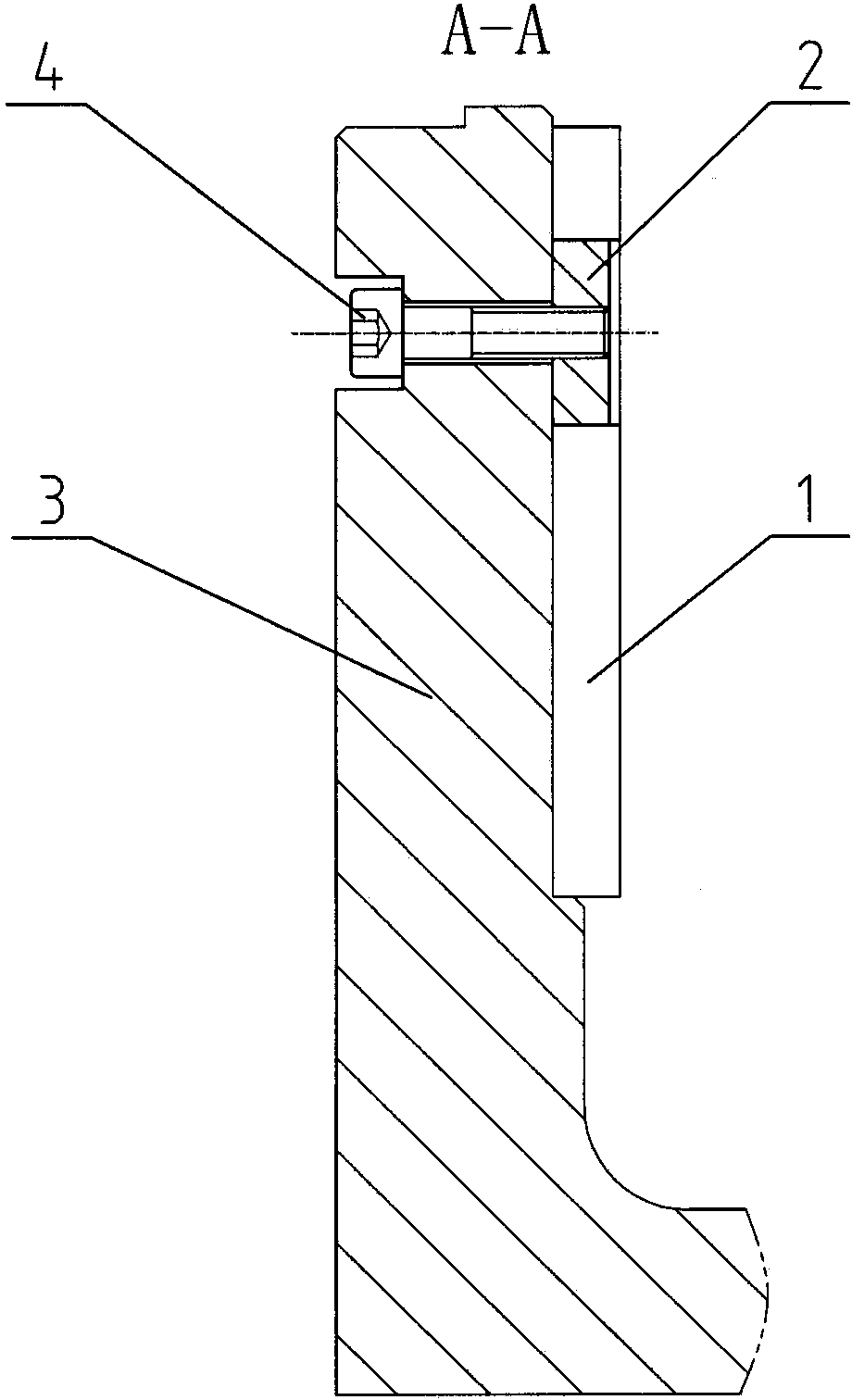

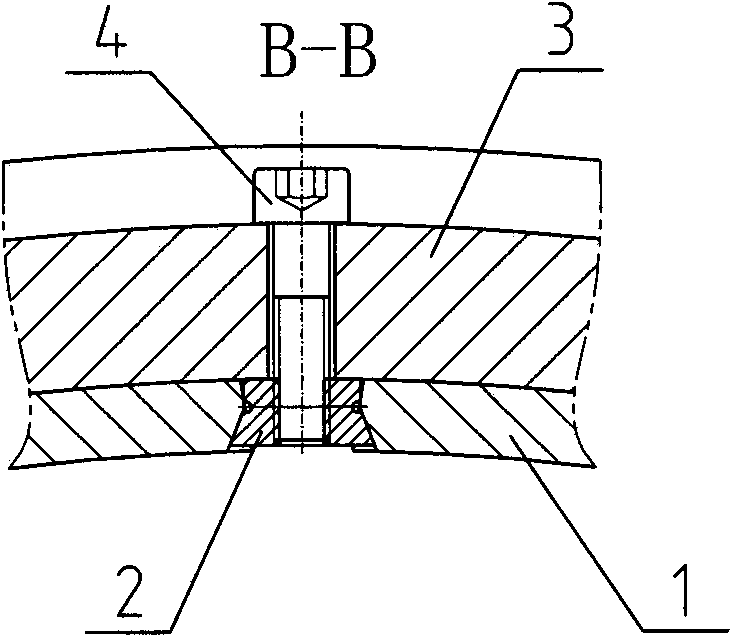

[0015] according to Figure 1-7 The specific structure of the present invention will be described in detail. The permanent magnet fixing structure includes a permanent magnet 1 , a rotor bracket 3 for fixing the permanent magnet 1 , fixing pieces and other components. Wherein the fixing part is composed of a non-magnetically conductive fixing block 2 with a threaded hole matched with the permanent magnet 1 and a non-magnetically conductive hexagon socket head bolt 4 coated with a locking agent on the thread end. The non-magnetic fixed block 2 is processed by a special mold, which is suitable for mass production, and the non-magnetic hexagon socket bolt 4 is a standard part in the national standard. The two sides of the permanent magnet 1 are provided with positioning grooves 5, and the rotor support 3 is distributed along the circumference with cylindrical through holes with the same number as the permanent magnets and grooves or countersinks for placing non-magnetic hexagon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com