Office keyboard key printing equipment

A kind of printing equipment and office technology, which is applied in the field of key printing equipment on office keyboards, which can solve the problems of manpower consumption, difficult collection of keyboards, and inability to locate keyboards, and achieve the effect of improving printing efficiency and facilitating collection by sliding down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

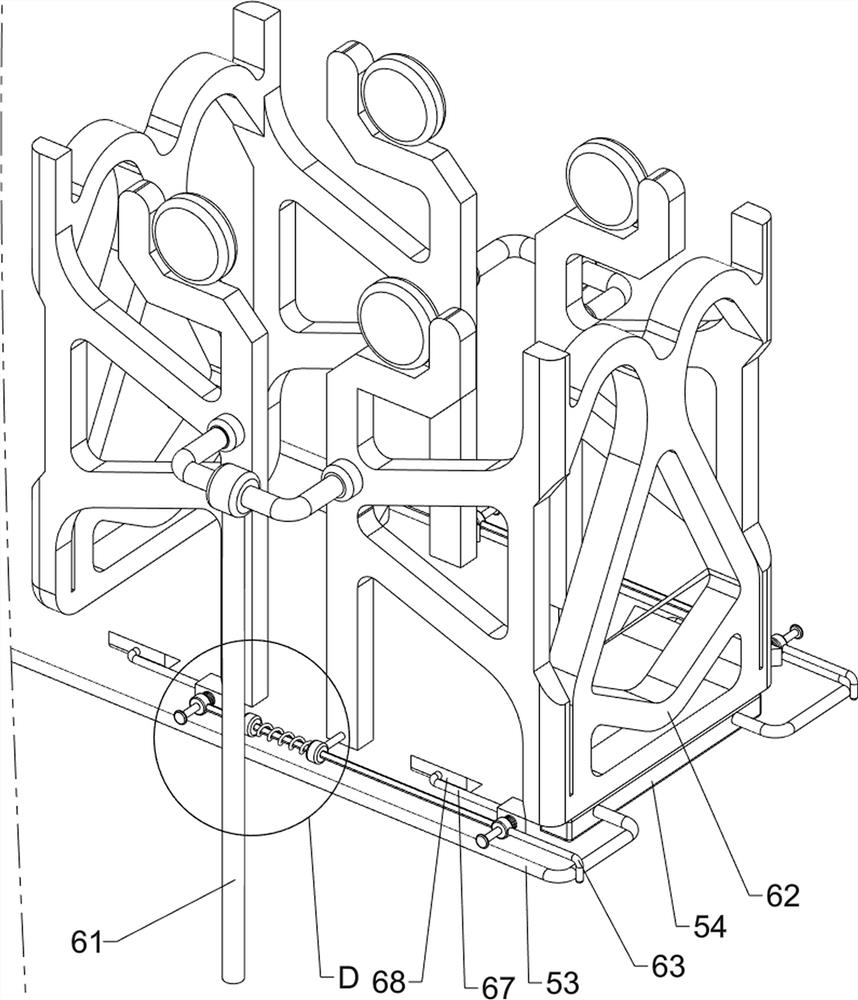

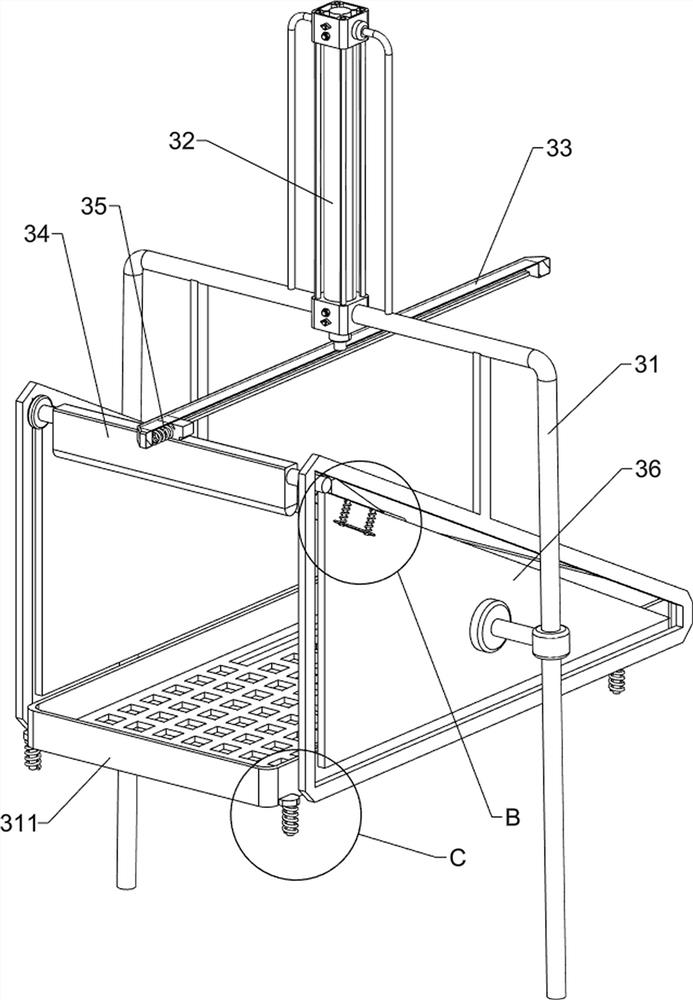

[0036] A key printing device on a keyboard for office use, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 As shown, it includes a base 1 , a placing component 2 and a printing component 3 , the placing component 2 is arranged on the upper part of the base 1 , and the printing component 3 is arranged between the left side of the upper part of the base 1 and the placing component 2 .

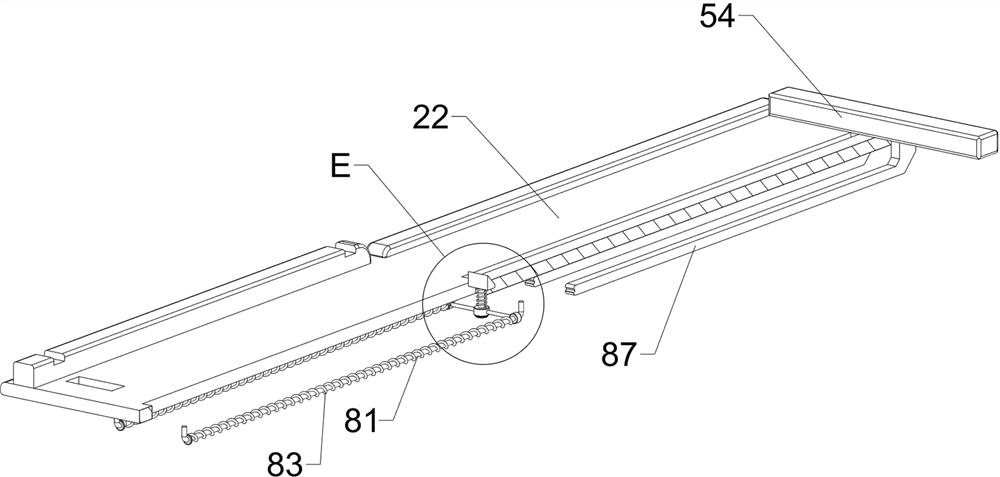

[0037]The placement assembly 2 includes a first support frame 21, a placement plate 22, a first baffle plate 23, a first guide rod 24, a first wedge block 25 and a first spring 26, the top of the base 1 is connected with the first support frame 21, the first A support frame 21 top is connected with a placement plate 22, the left side of the top of the placement plate 22 is connected with a first baffle plate 23 symmetrically front and rear, and the middle of the top of the placement plate 22 is connected with a first guide rod 24 in a symmetrical front and back s...

Embodiment 2

[0041] On the basis of Example 1, such as figure 1 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 and Figure 13 As shown, a positioning assembly 4 is also included, and the positioning assembly 4 includes a fourth guide rod 41, a stopper 42 and a fifth spring 43, and a pair of fourth guide rods 41 are connected symmetrically front and rear on the left side of the bottom of the placement plate 22. The four guide rods 41 are all symmetrical front and back, every pair of fourth guide rods 41 upper sides are slidably connected with stoppers 42, the stoppers 42 are slidably connected with the placement plate 22, and the front and back of the stoppers 42 and the placement plate 22 are all slidably connected. A fifth spring 43 is symmetrically connected, and the fifth spring 43 is sleeved on the fourth guide rod 41 .

[0042] When the keyboard is pushed from the right side to the underside of the paint plate 311, it is blocked by the stopper 42 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com