Automatic chopstick paint scraping equipment for tableware production

A chopsticks, automatic technology, applied in the direction of pretreatment surface, device for coating liquid on the surface, conveyor objects, etc., can solve the problems of inconvenient collection of chopsticks, difficult to clean paint, low efficiency, etc., to improve the efficiency of painting paint, maintain Neat and tidy, easy to clean up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

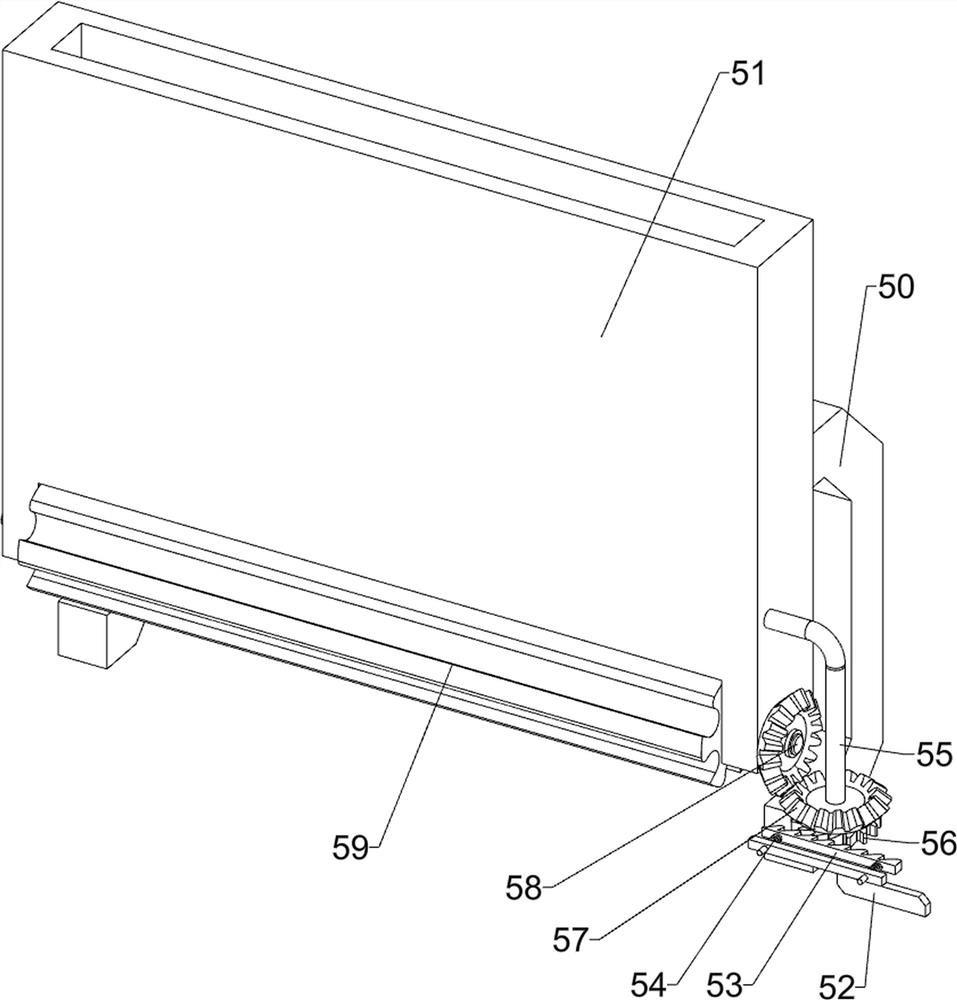

[0028] A chopsticks automatic painting equipment for tableware production, such as figure 1 , figure 2 and image 3 As shown, it includes a substrate 1 , a drying mechanism 2 and a paint pulling mechanism 3 . The drying mechanism 2 is arranged in the middle of the upper side of the substrate 1 , and the paint pulling mechanism 3 is arranged between the upper right side of the substrate 1 and the drying mechanism 2 .

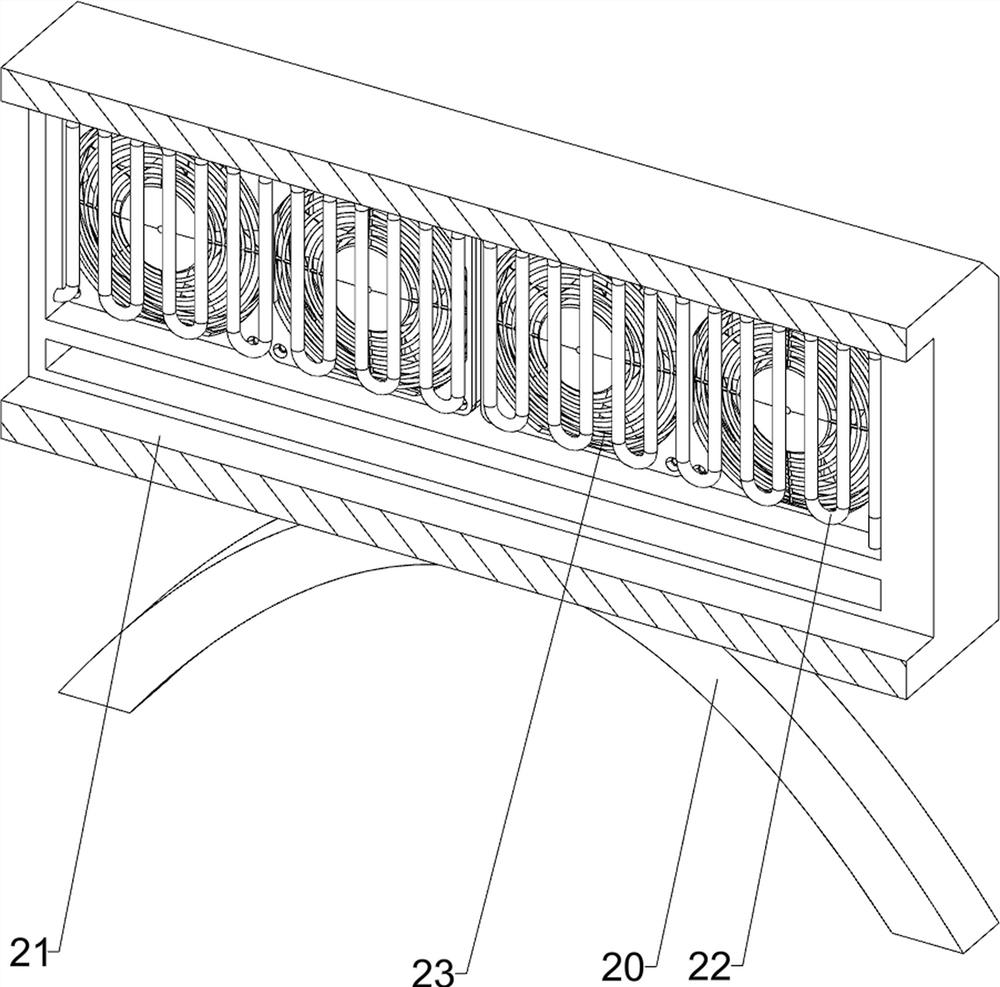

[0029] The drying mechanism 2 includes a support seat 20, a fixed box 21, a heating pipe 22 and a fan 23. The upper middle part of the substrate 1 is connected with the support seat 20 symmetrically front and back, and the upper part of the support seat 20 is connected with a fixed box 21. The front and rear of the fixed box 21 Four fans 23 are evenly spaced on both sides, and heating pipes 22 are symmetrically connected between the left and right sides inside the fixed box 21 .

[0030] Paint pulling mechanism 3 comprises first connecting rod 30, first spring...

Embodiment 2

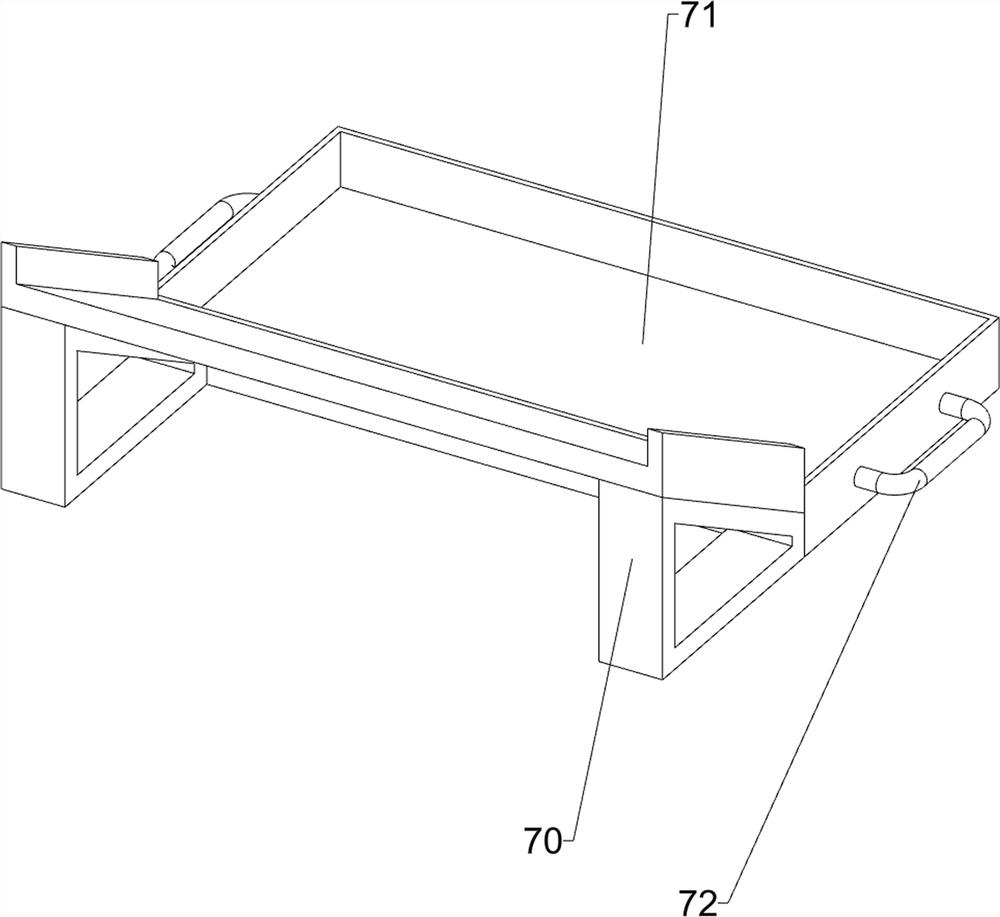

[0033] On the basis of Example 1, such as figure 1 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, it also includes a pushing assembly 4, and the pushing assembly 4 includes a support frame 40, a cylinder 41, a second connecting rod 42, a push rod 43, a placement table 44, a chute 45, a third spring 46, a second slide Block 47, wedge-shaped rod 48 and long rod 49, substrate 1 top is connected with support frame 40, and cylinder 41 is installed on the left front side of support frame 40 top, is connected with long rod 49 on the right side of cylinder 41 piston rod, and long rod 49 right side is connected with The second connecting rod 42, the rear side of the second connecting rod 42 bottom is connected with a push rod 43, and the right rear side of the support frame 40 top is connected with a placement table 44, and the placement table 44 is located on the right side of the right pulley 39, and the placement table 44 is connected to the top. Rod 43 is slidably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com