Automatic cutting device for stone lantern

An automatic cutting device and lantern technology, applied in the direction of used abrasive processing devices, stone processing equipment, stone processing tools, etc., can solve the problems of inability to remove and collect waste, save manpower, expand the scope of use, and reduce waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

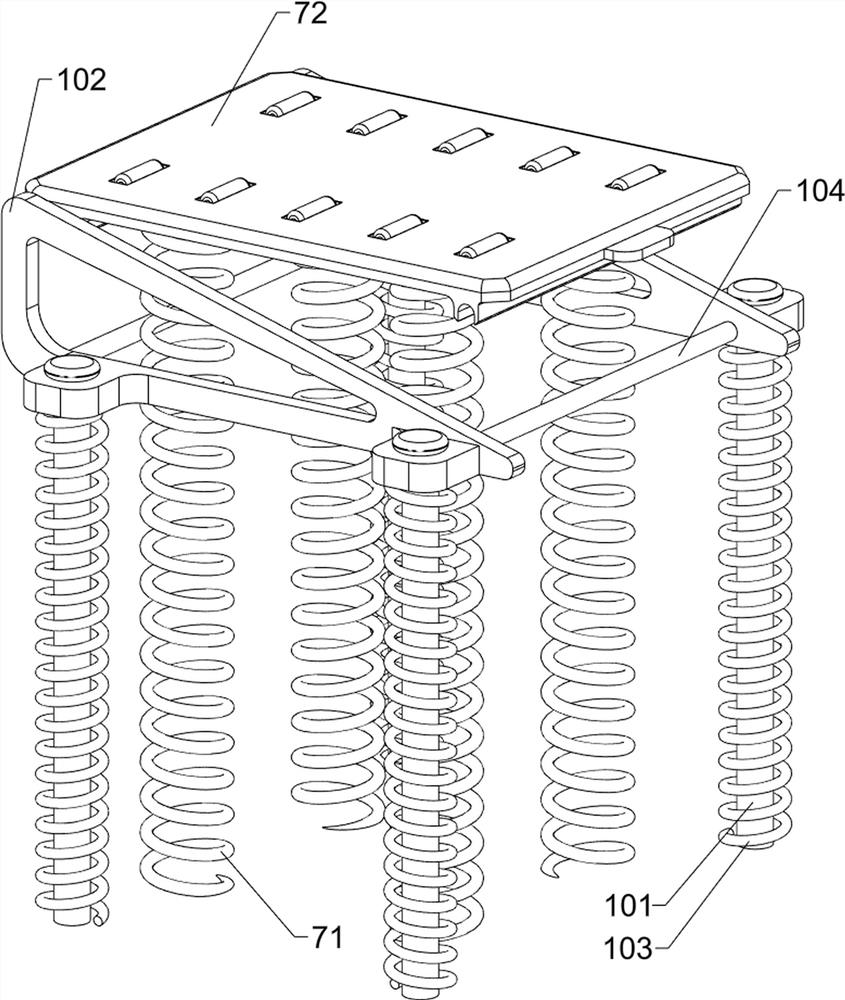

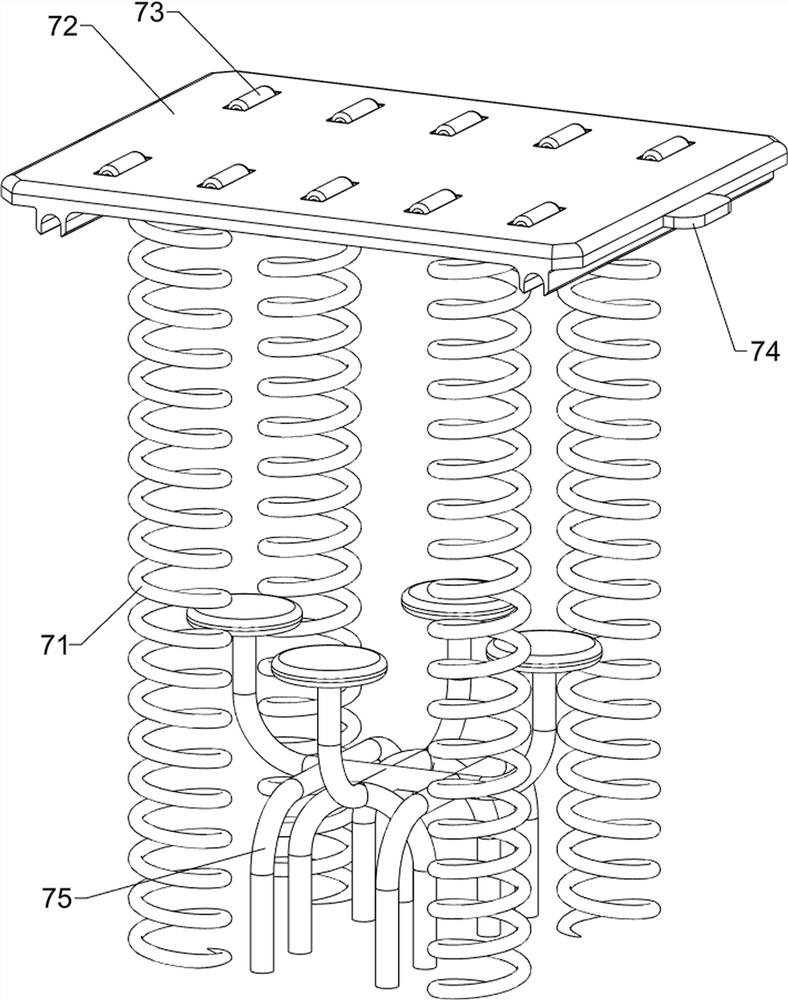

[0031] An automatic cutting device for stone lanterns, such as figure 1 , figure 2 with image 3 As shown, it includes a base 1, a first support frame 2, a motor 3, a placement assembly 4 and a liquid cutting assembly 5, and the first support frame 2 is connected to the front and rear sides of the upper part of the base 1, and the first support frame 2 is connected to the upper part of the base 1. A placement assembly 4 is arranged between them, a liquid cutting assembly 5 is arranged between the upper side of the first support frame 2 , and a motor 3 is installed on the lower part of the liquid cutting assembly 5 .

[0032] The placement assembly 4 includes a support foot 41, a first placement plate 42 and a first roller 43. The right side of the upper part of the base 1 is connected with a support foot 41, and the support foot 41 is connected with the first support frame 2 on both sides. The first support frame 2 A first placement board 42 is connected between the upper s...

Embodiment 2

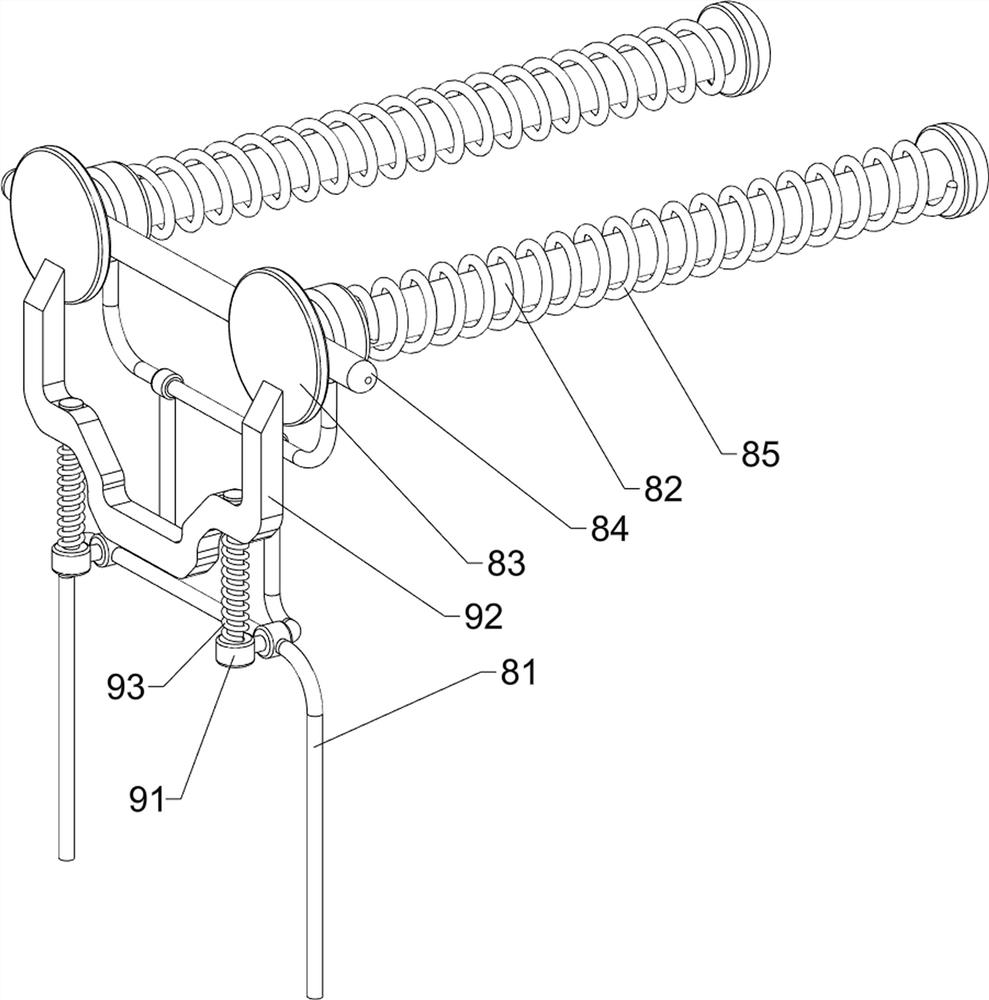

[0036] On the basis of Example 1, such as Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 As shown, a positioning assembly 6 is also included. The positioning assembly 6 includes a stopper 61, a first wedge-shaped block 62, a slider 63, a first spring 64 and a handle 65. A slider 63 is connected, the upper side of the slider 63 is connected with a first spring 64, the upper side of the first spring 64 is connected with a stopper 61, and the left side of the lower part of the stopper 61 is symmetrically connected with a first wedge-shaped block 62 front and rear, the second A wedge block 62 cooperates with the first placement plate 42 , and a handle 65 is connected to the upper side of the middle part of the stop block 61 .

[0037] When vigorously pushing the lantern to move to the left, it will eventually be blocked by the stopper 61 and cannot move freely. Sometimes it is necessary to adjust the cutting position according to the actual situation. If the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com