Patents

Literature

116results about How to "Achieve shedding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

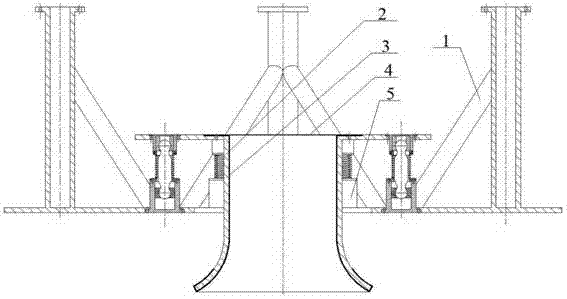

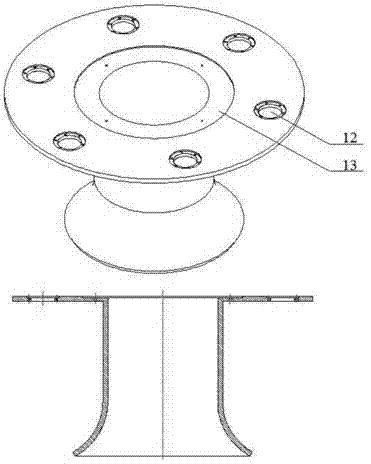

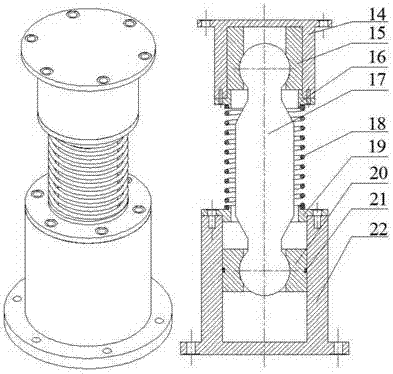

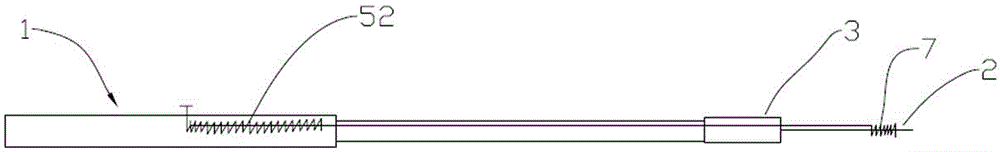

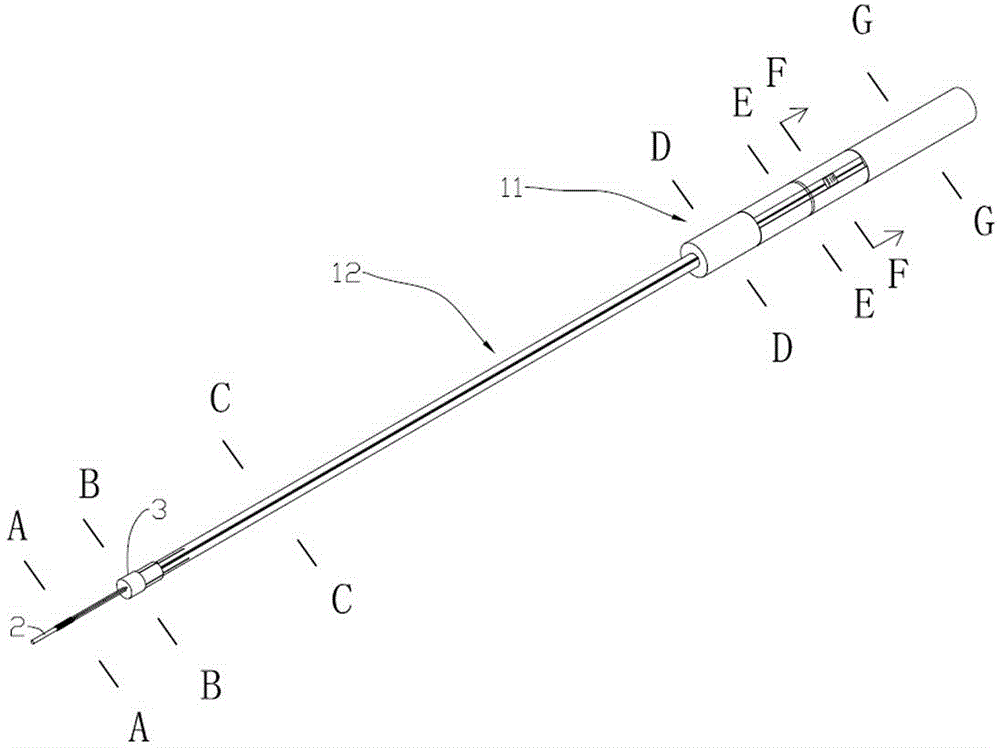

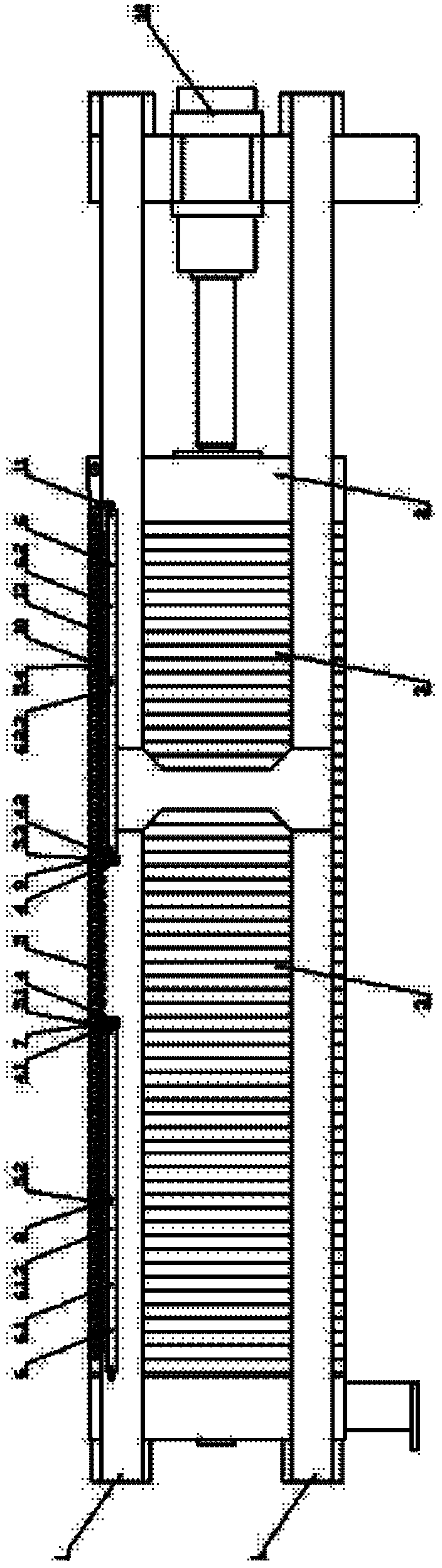

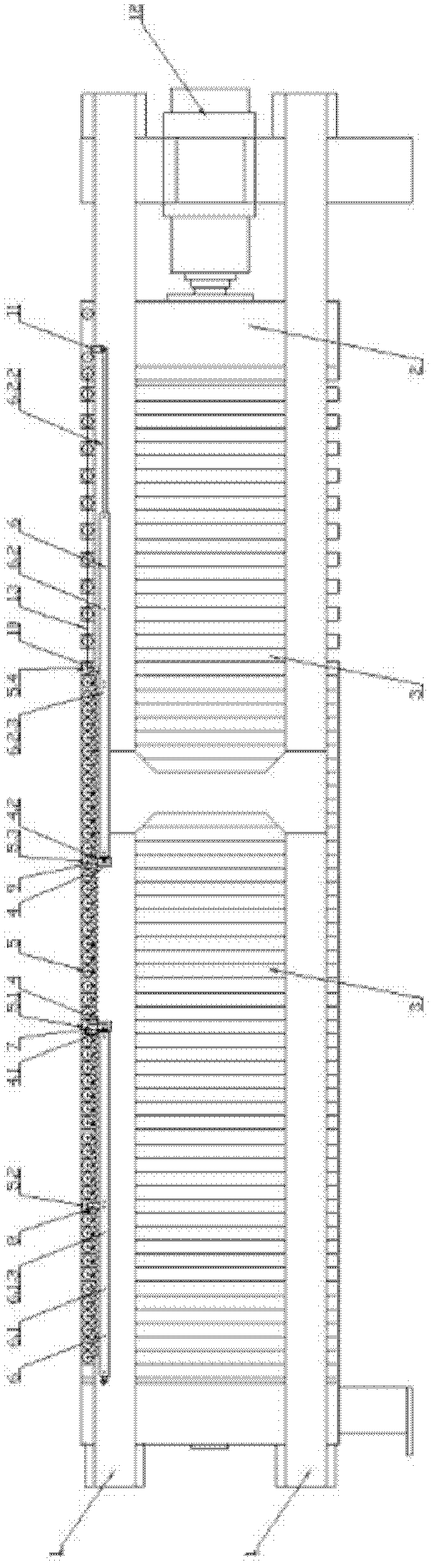

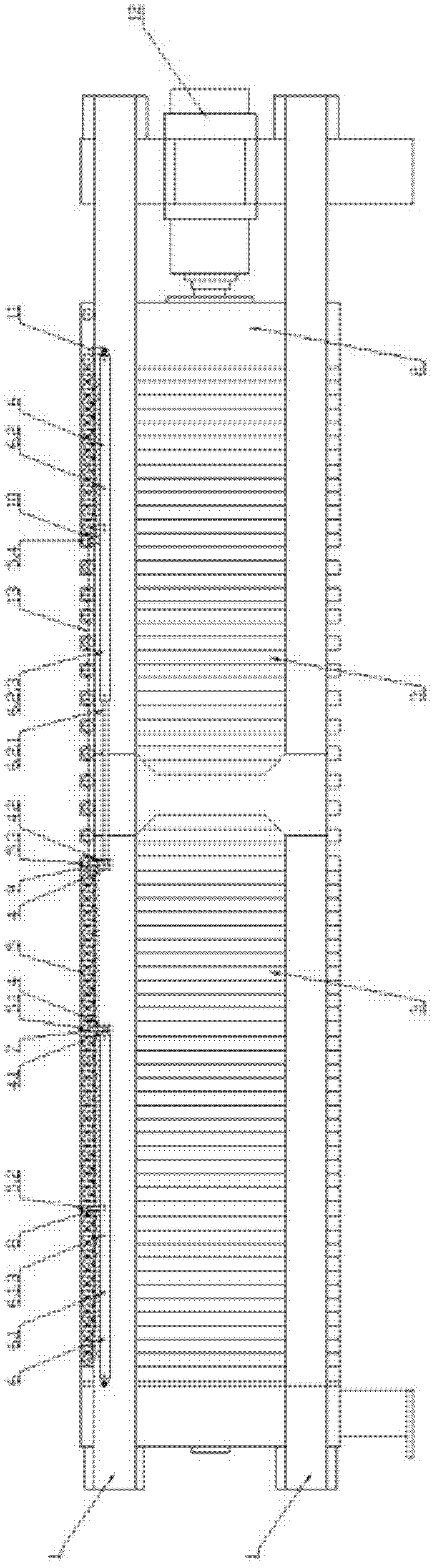

Anti-blocking-and-hanging drilling well water-secluding pipe recovery guiding device

ActiveCN105443058AAvoid hanging problemsInhibit sheddingBorehole/well accessoriesWell drillingMouth shape

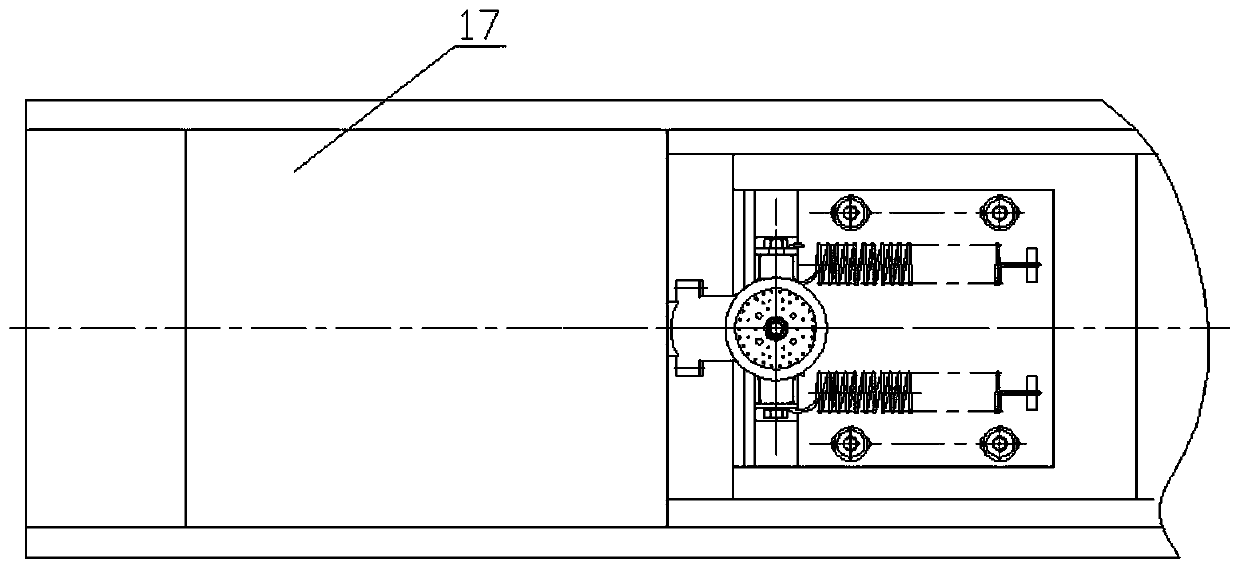

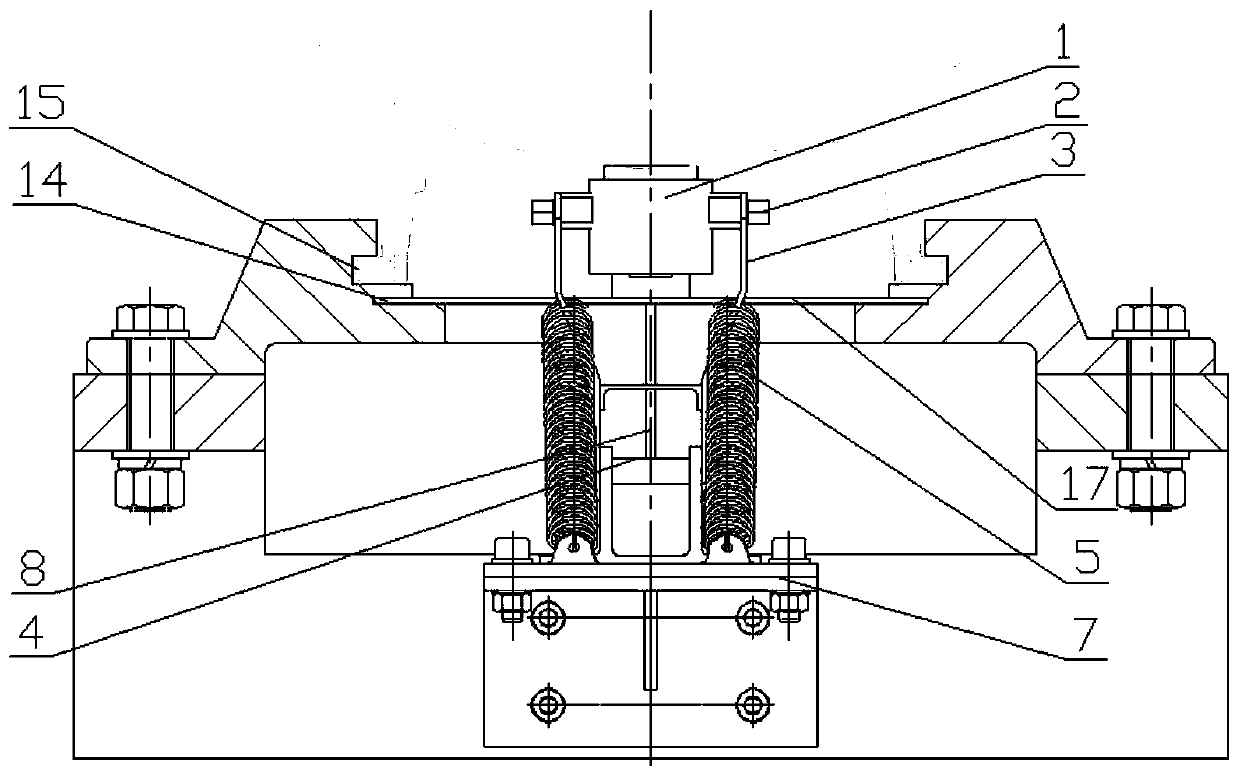

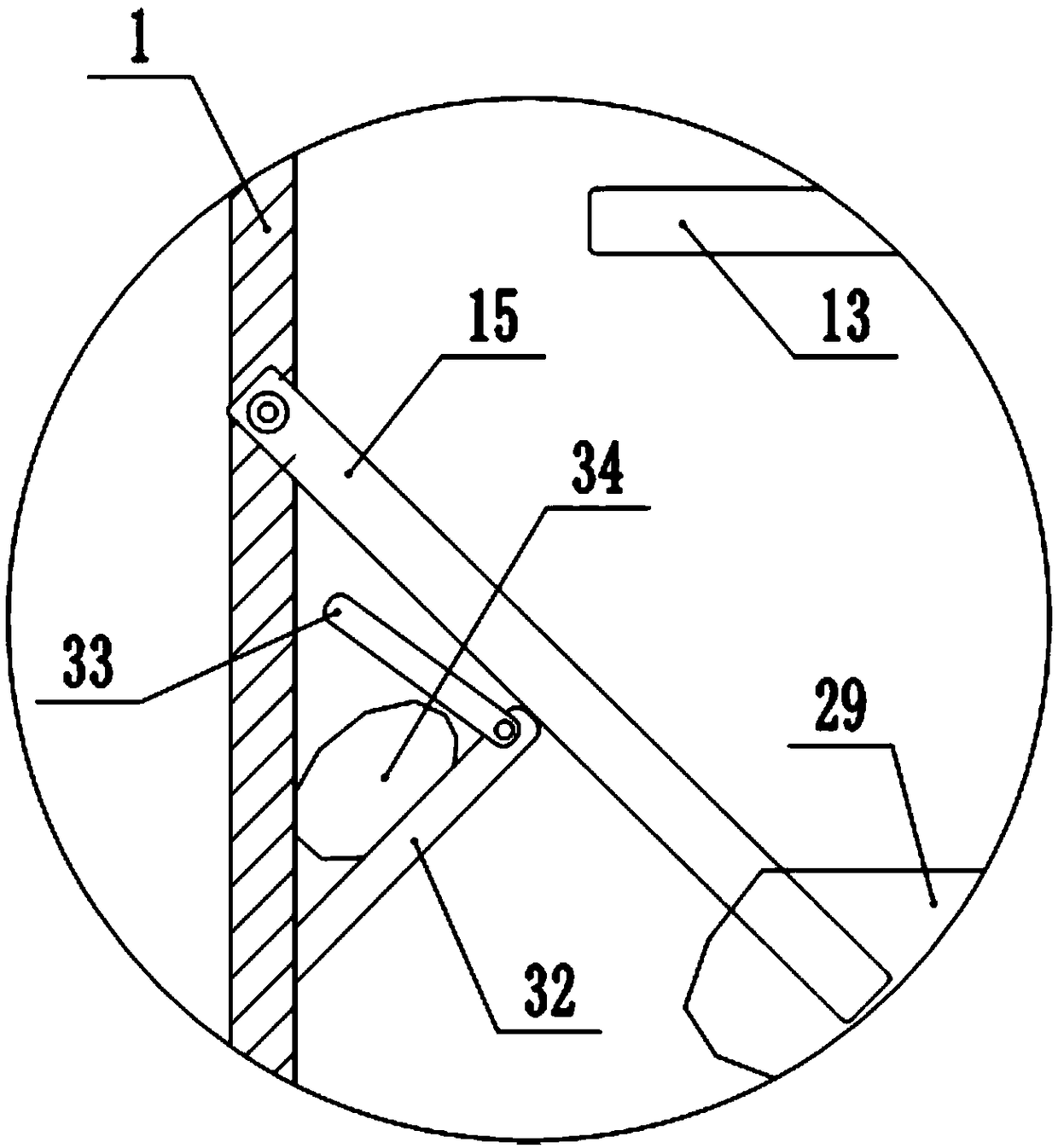

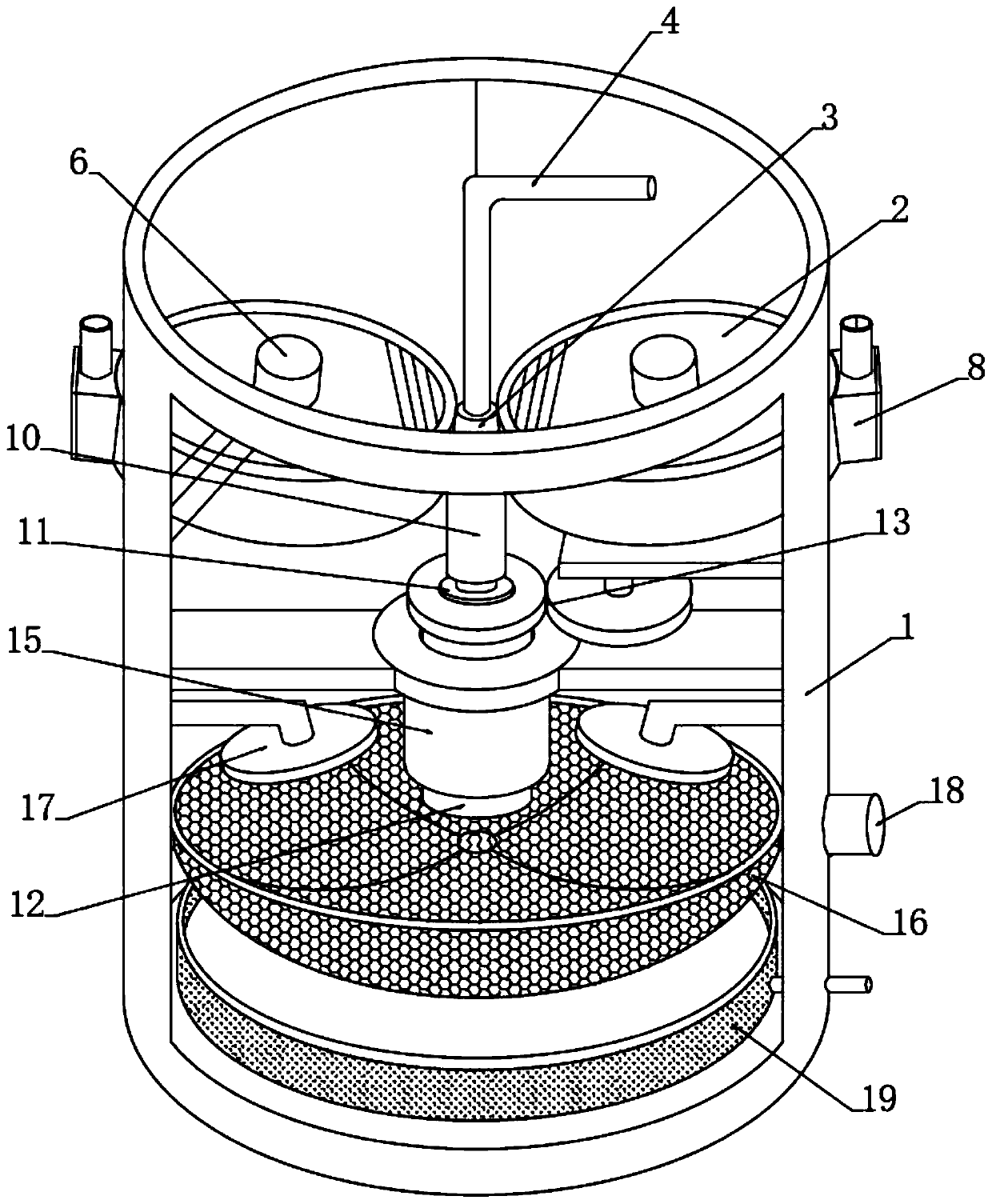

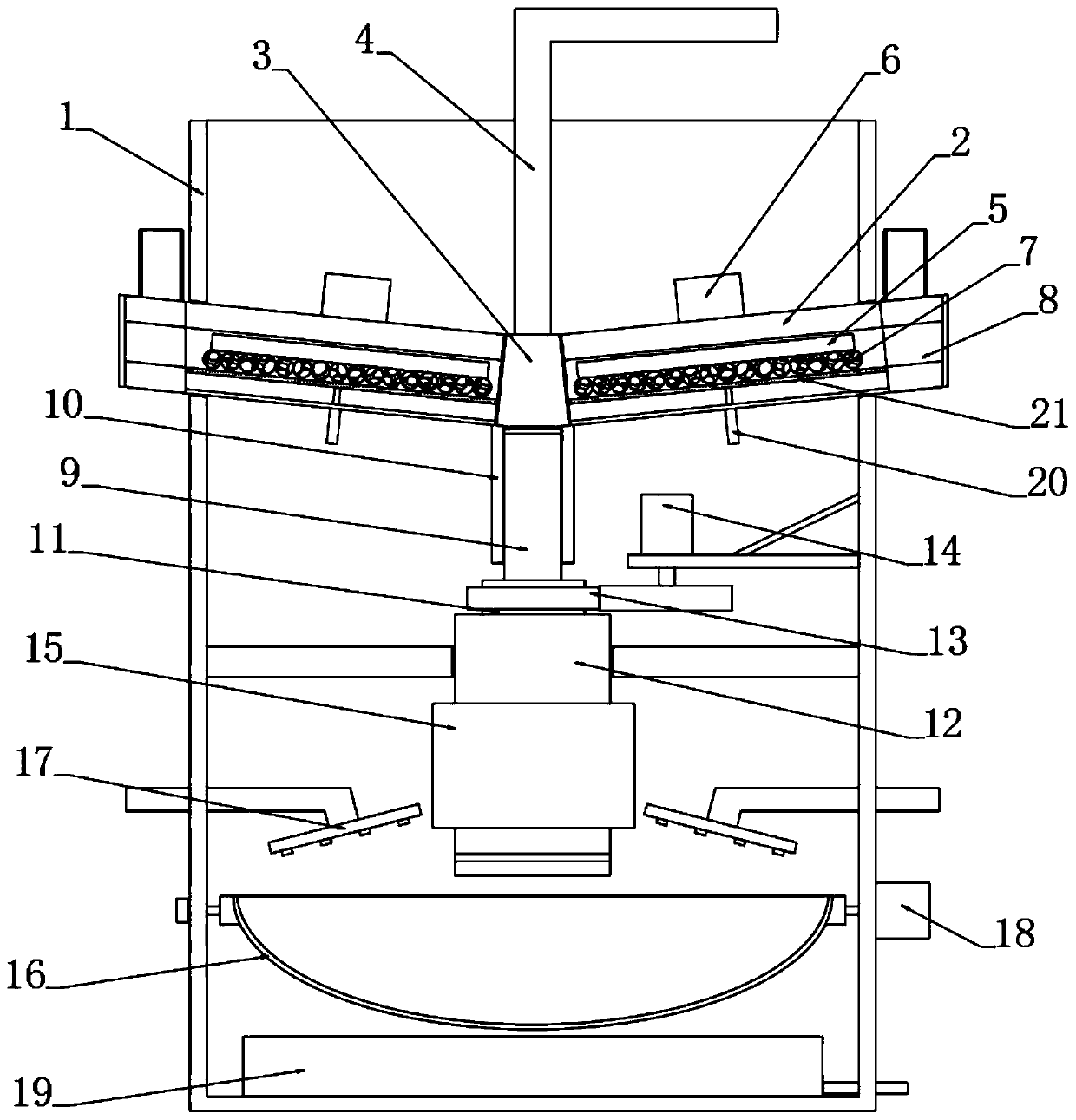

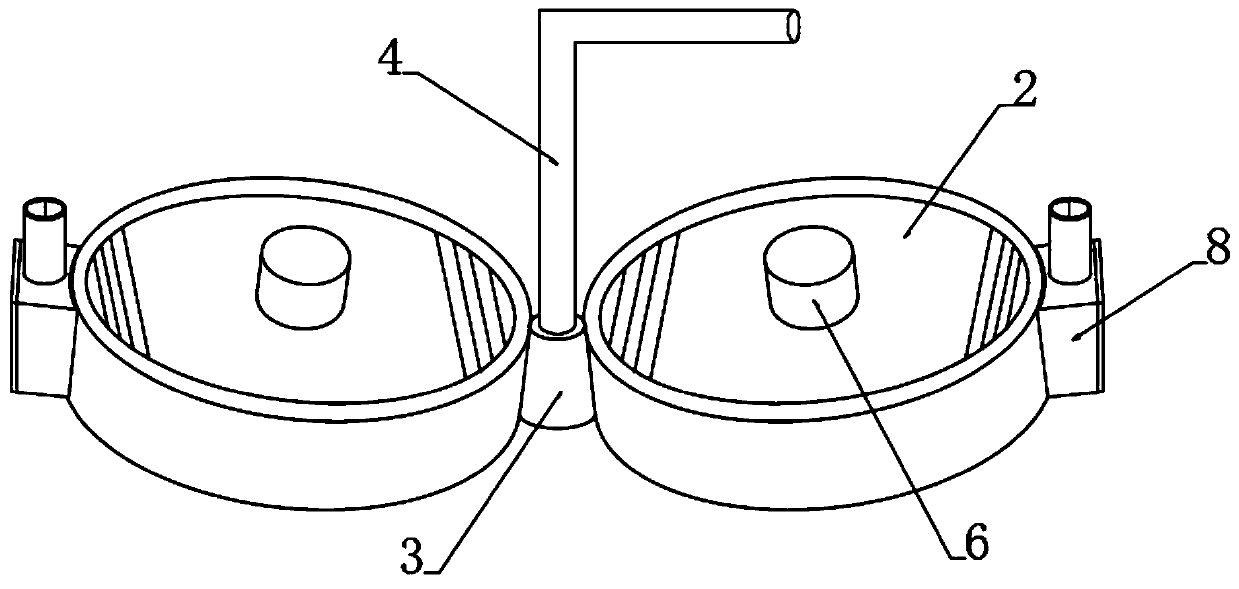

The invention relates to an anti-blocking-and-hanging drilling well water-secluding pipe recovery guiding device. The device is characterized by comprising a support, a guiding chamber, a rubber sleeve, a rubber sleeve pressing ring and a supporting device; the support is provided with multiple connecting legs, multiple supporting device lower portion mounting holes are formed in the outer side of the support, and a guiding chamber mounting hole is formed in the middle of the support; the guiding chamber is in a horn-mouth shape, the rubber sleeve is arranged inside the guiding chamber, and the rubber sleeve pressing ring is arranged at the top of the guiding chamber; the supporting device comprises an upper supporting barrel, a wearproof bushing, an upper supporting barrel cover, a connecting rod, a spring, a lower supporting barrel cover, a piston, a piston embracing clamp and a lower supporting barrel; the wearproof bushing is arranged inside the upper supporting barrel, and the piston is arranged inside the lower supporting barrel; a groove is formed at the outer side of the piston, and the groove is matched with the piston embracing clamp; the upper end and the lower end of the connecting rod are both spherical bodies, and the spring is arranged at the outer side of the connecting rod; the spring is provided with an installing ring. The device is simple in structure, convenient to operate, high in reliability and easy and convenient to assemble and can be widely applied to all types of maritime water-secluding pipe anti-blocking-and-hanging recycling operation.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

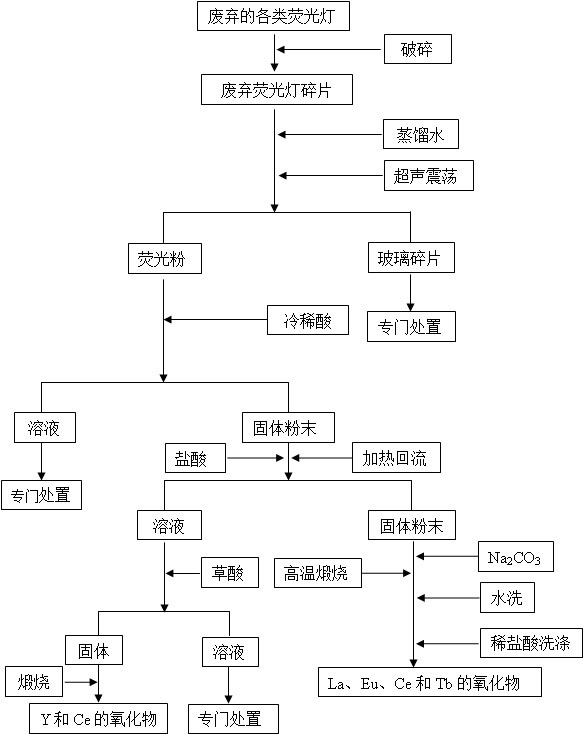

Method for recycling rear-earth elements form abandoned fluorescent lamps

InactiveCN102634667AAchieve sheddingAchieve separationProcess efficiency improvementOxalateRare-earth element

The invention relates to a method for recycling rear-earth elements form abandoned fluorescent lamps, wherein the method comprises the following steps of: breaking abandoned energy-saving lamps; separating fluorescent powder; and recycling rear-earth elements from the fluorescent powder. According to the invention, the method specifically comprises the following steps of: firstly breaking the abandoned energy-saving lamps mechanically in an enclosed container; separating the fluorescent powder out of the abandoned fluorescent lamps through a simple mechanical separation method; separating and recycling the rear-earth elements and other useful elements through carrying out a two-step acid dissolution method and adding oxalate for precipitation; fusing and refining solid powder insoluble in acid by using alkali metal carbonate; and then processing simply. Through the method provided by the invention, the reasonable recycling of all rear-earth element compositions in the abandoned energy-saving lamps can be realized, the rear-earth resources are expected to be comprehensively recycled maximally, and the method is simple and has wide application prospect.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

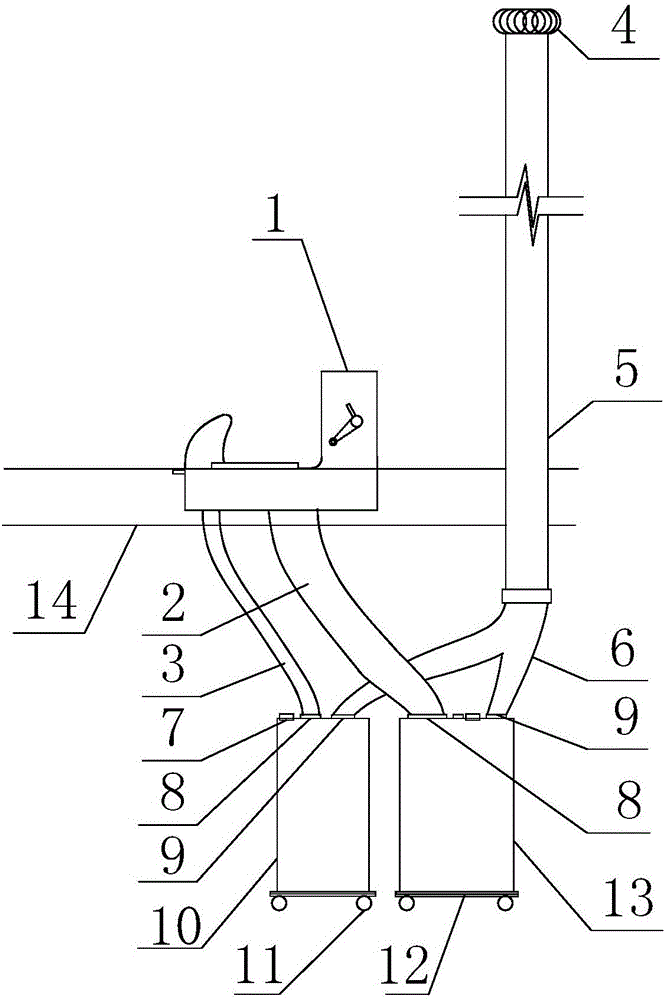

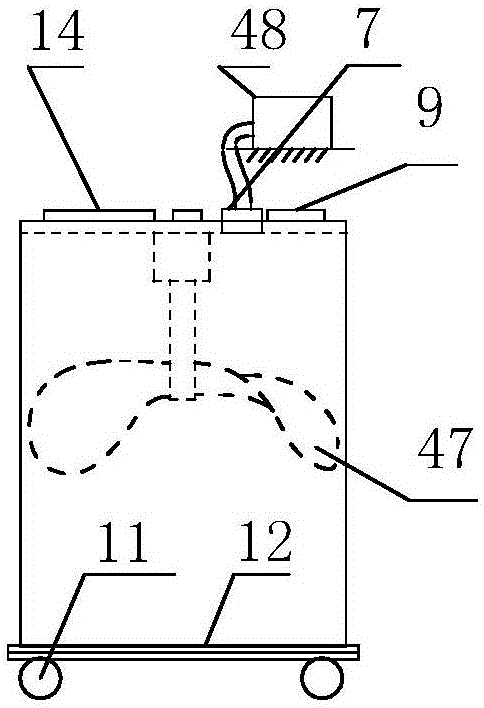

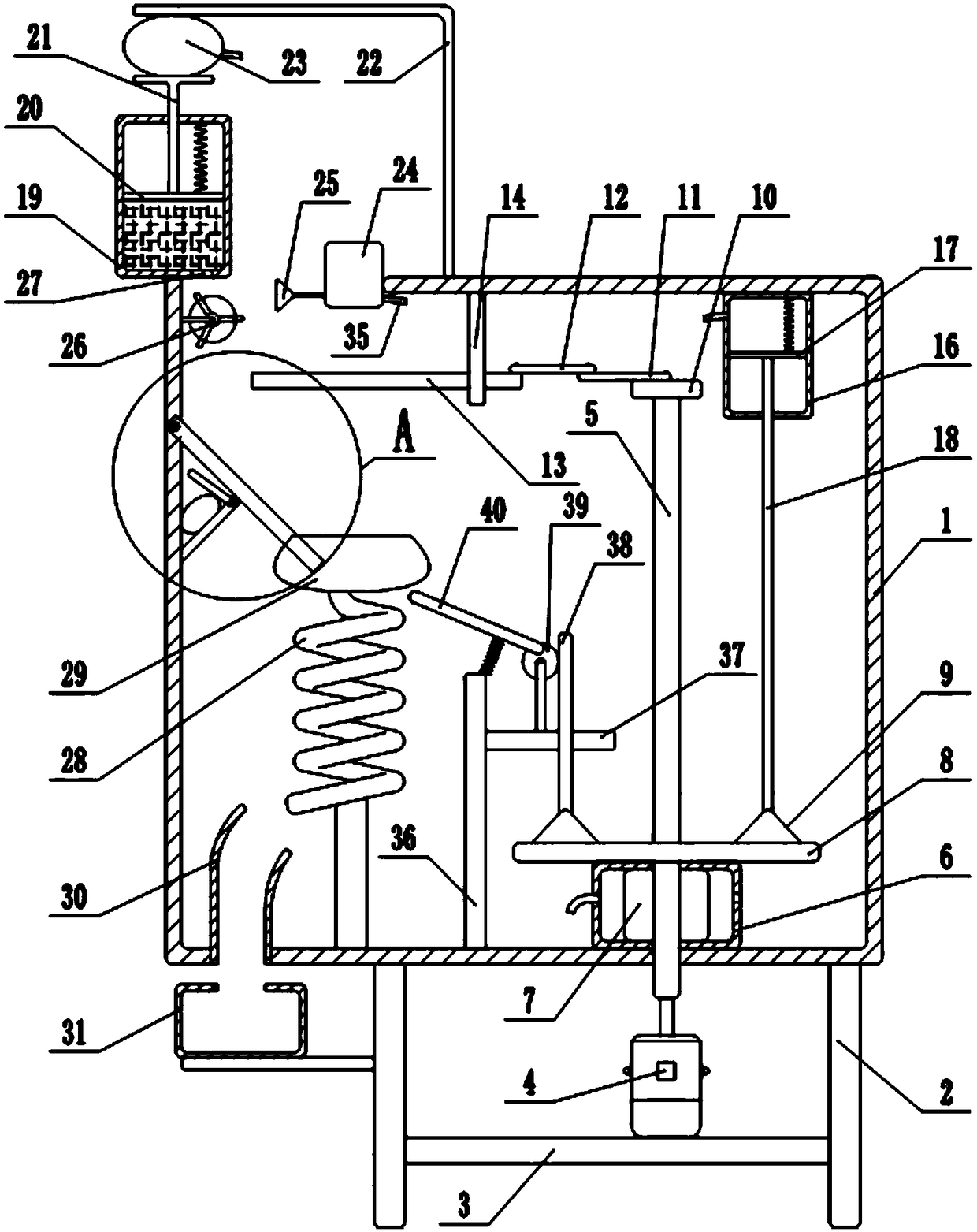

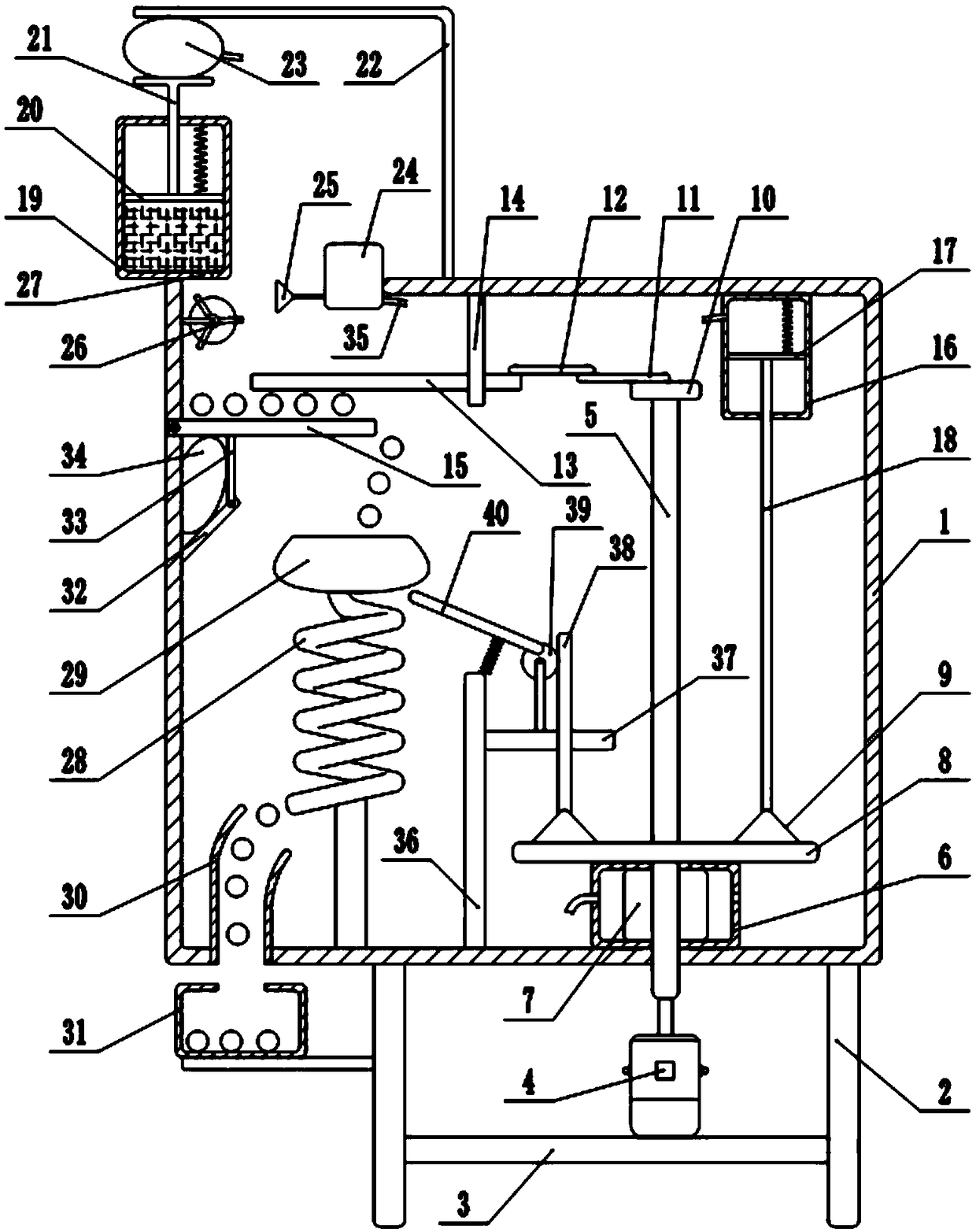

Flushing-free excrement and urine separating collecting and treatment system of public washroom

ActiveCN106214046AImprove processing efficiencyImprove utilization efficiencyBathroom accessoriesWater resourcesContamination

Provided is a flushing-free excrement and urine separating collecting and treatment system of a public washroom. A urine drainage pipe and an excrement discharge pipe separated from the urine drainage pipe are arranged in the public washroom and communicated with a urine collecting container and an excrement collecting container, the tops of the containers are communicated with an air drainage pipe, and an excrement-urine separation toilet stool comprises a bag storage box, a bag containing mechanism and an odor separating plate opening mechanism. Stacked excrement bags are stored in the bag storage box, the side wall of an inlet of an excrement channel is provided with a transversely-arranged bag hanging groove, the excrement bag on the innermost side is provided with the bag containing mechanism, and the excrement bag on the innermost side falls off through a chute and is arranged in the bag hanging groove. An odor separating plate controlled by a bag falling switch is arranged at the bottom of the excrement channel, and the bag falling switch is controlled to enable the excrement bags to slide into the collecting container after defecating. According to the system, water resources are saved, environmental friendliness is achieved, the problems of toilet deodorization and excrement falling opening contamination are solved, the treatment and utilization efficiency of excrement and urine organic fertilizer resources is greatly improved, and wide application prospects are achieved.

Owner:云南八卫科技有限公司

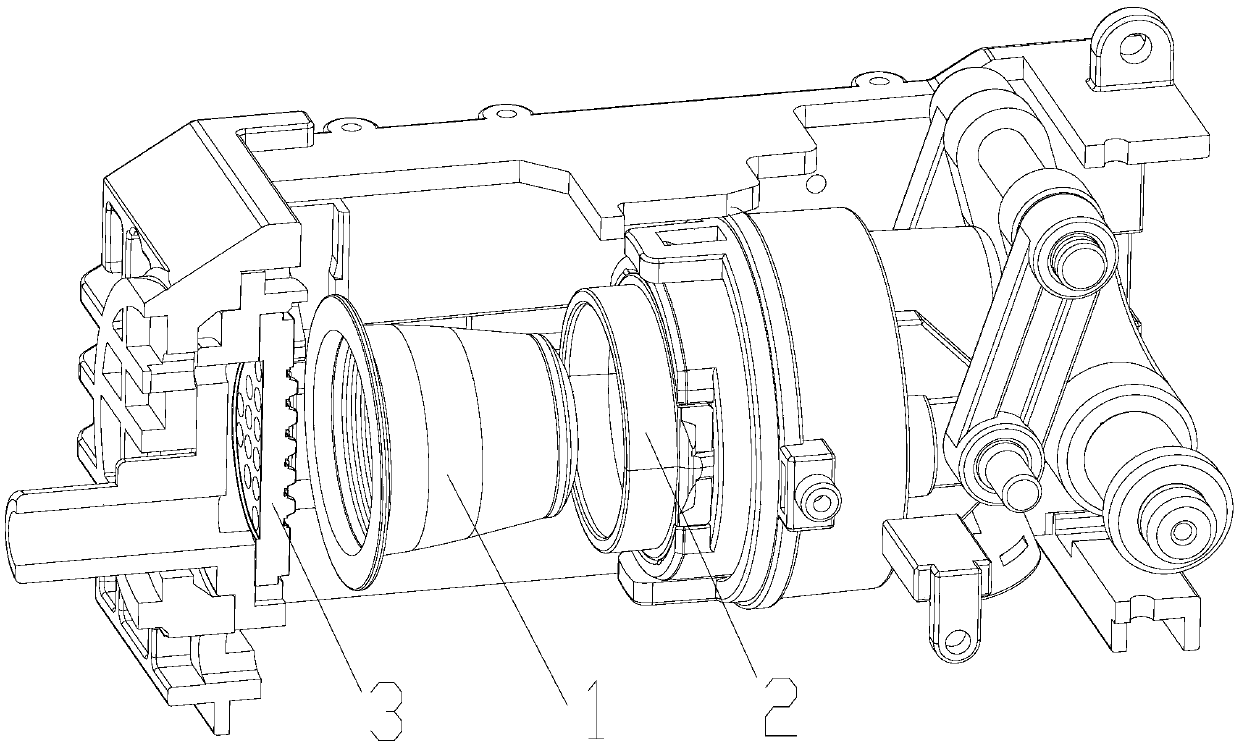

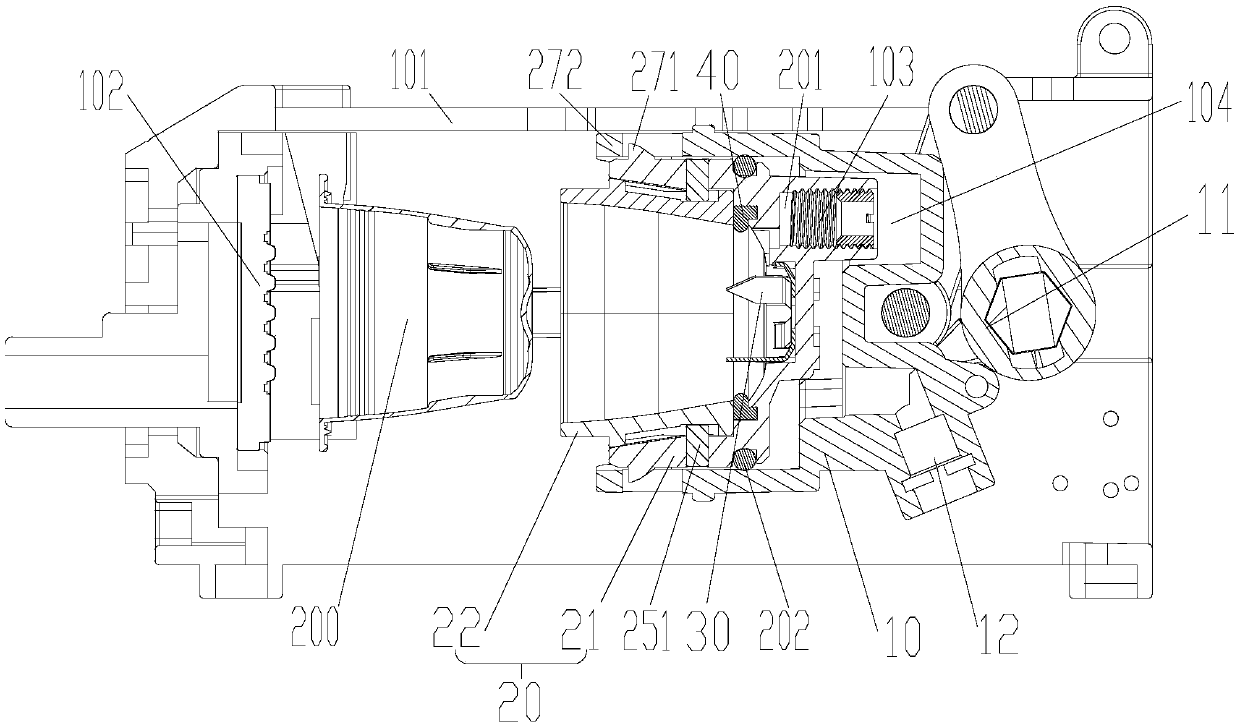

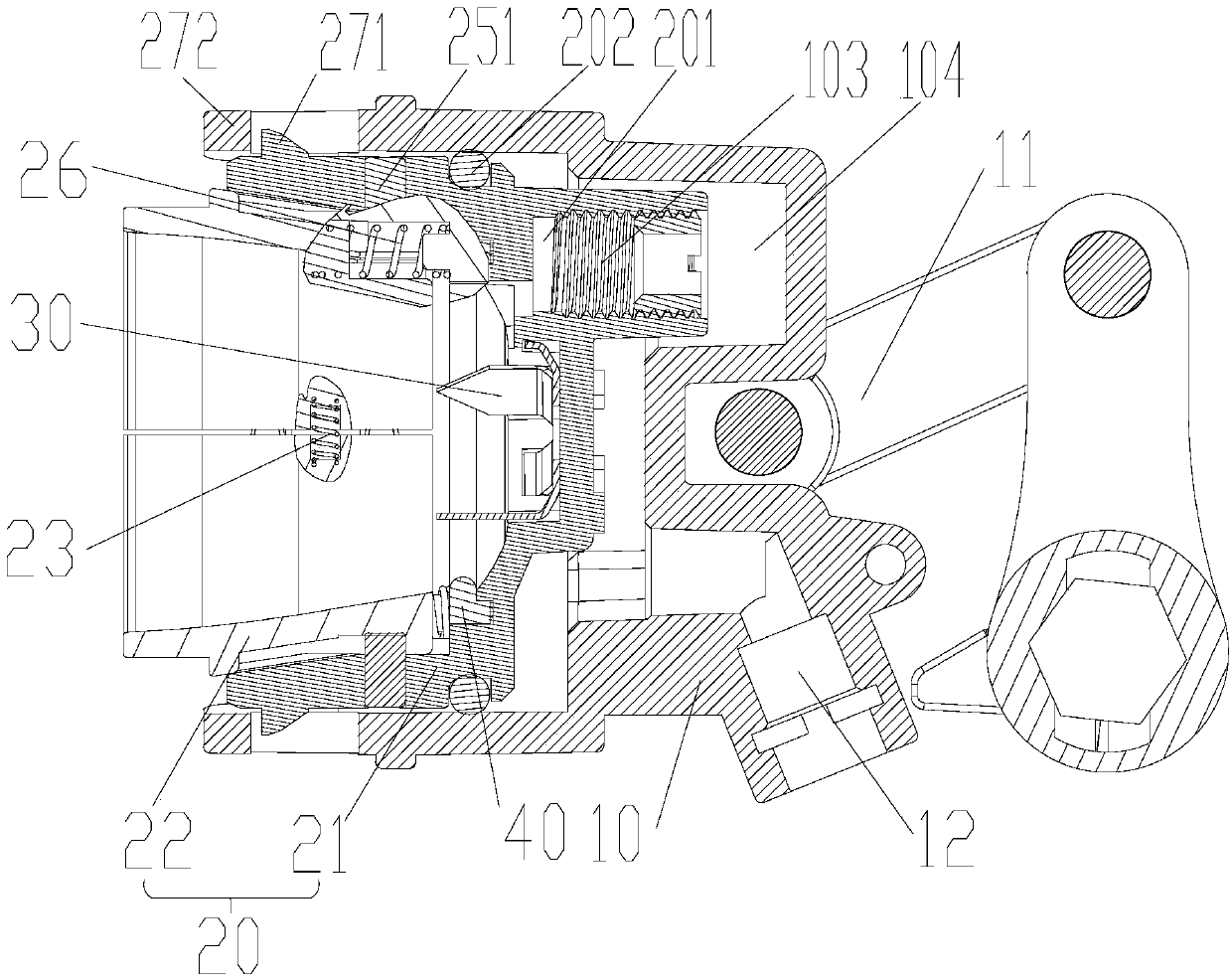

Rapid fall-off device for rocket launching electrical connector

ActiveCN109696082ASimple structureImprove reliabilityRocket launchersCoupling device detailsRocket launchElectricity

The invention discloses a rapid fall-off device for a rocket launching electrical connector. The rapid fall-off device comprises a plug shell, a rotary arm, a rotary arm shaft, a rotary arm bracket, abase, a tension spring, a pulling rope, a shifting fork, a gas cover plate and a compressed spring linkage mechanism; the plug shell is used for fixing a plug of the external electrical connector, the plug shell and the rotary arm are hinged, the rotary arm is movably connected with the rotary arm bracket through the rotary arm shaft, the rotary arm bracket is fixed to the base, and the tension spring is fixed between the rotary arm and the base; one end of the shifting fork is fixed to the rotary arm shaft, the other end of the shifting fork abuts against the gas cover plate, and the middleof the shifting fork is connected with the rotary arm through the pulling rope; and when a rocket is ignited to move, the plug shell is driven to move horizontally, under the action of the tension spring, the rotary arm drives the plug shell to rotate around the rotary arm shaft, the plug is separated from a socket on the rocket, meanwhile, the rotary arm drives the shifting fork to rotate throughthe pulling rope, limiting to the gas cover plate is relieved, and the compressed spring linkage mechanism drives the gas cover plate to cover the plug. According to the rapid fall-off device, the electrical connector can be ignited firstly and then falls off, and the rocket is launched reliably and accurately.

Owner:XIAN AEROSPACE PROPULSION TECH INST

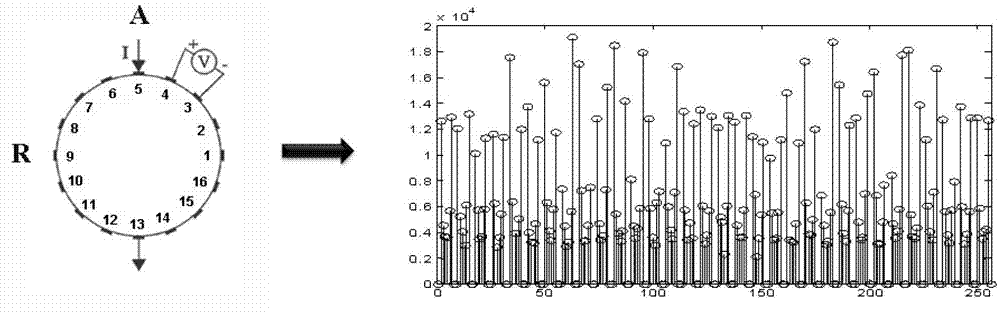

Abnormal electrode connection detecting method for impedance detection

InactiveCN103040466ADetermine the connection statusAchieve sheddingDiagnostic recording/measuringSensorsPhysicsImpedance imaging

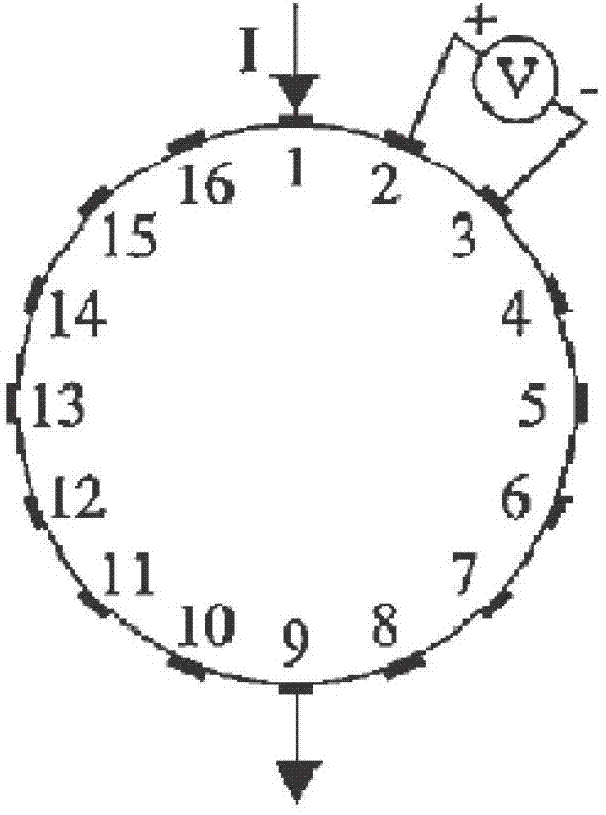

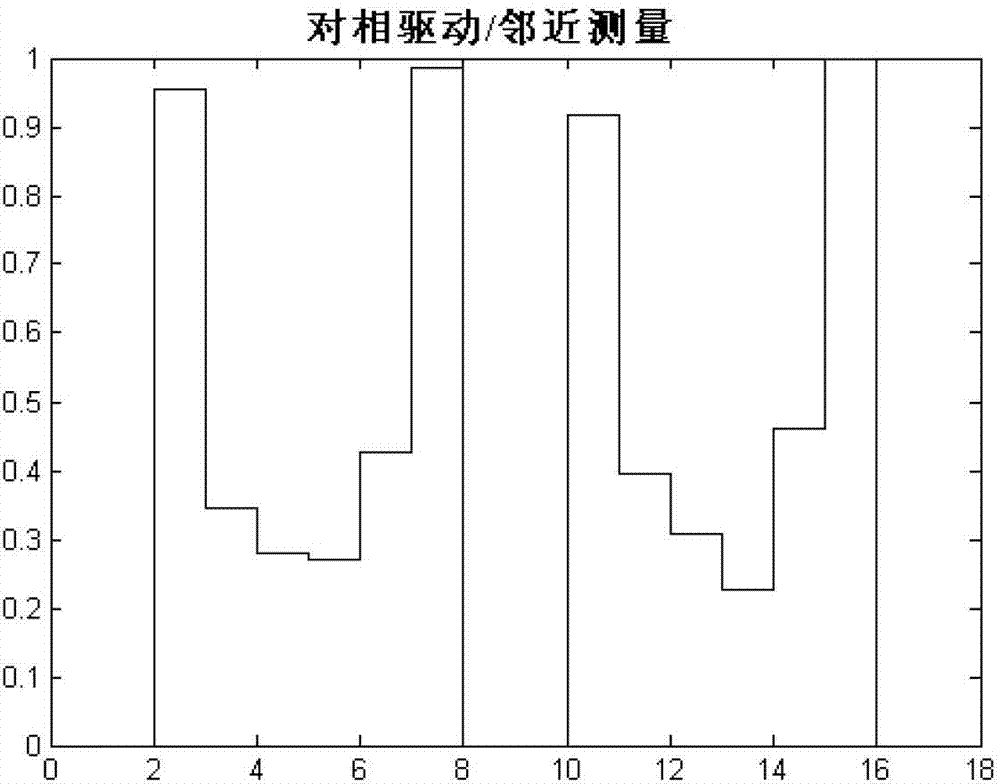

The invention discloses an abnormal electrode connection detecting method for impedance detection. The abnormal electrode connection detecting method includes utilizing acquired original data of an impedance imaging system to calculate relevancy of acquired data of various electrode channels, acquiring electrode variable coefficient according to the relevancy, and judging whether electrode connection is abnormal or poor in contact when variable coefficient of a certain electrode is larger than the set threshold value. The abnormal electrode connection detecting method is an automatic, quick and accurate electrode connection state detection method, and can provide reliable basis for clinical staff to adjust electrode connection in time and guarantee continuity and completeness of impedance image monitoring.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

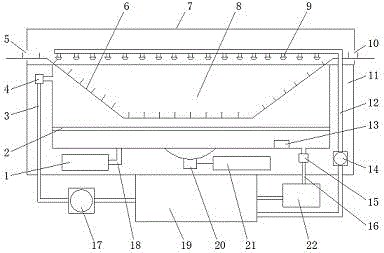

High-pressure disinfection and cleaning integrated machine

InactiveCN105750262AAvoid colliding with each otherAvoid manual handlingCleaning using liquidsFood treatmentOzone generatorWater flow

The invention discloses a high-pressure disinfection and cleaning integrated machine. The high-pressure disinfection and cleaning integrated machine comprises an ozone generator, a conveying belt, a cleaning tank, high-pressure nozzles, a water tank body, a cleaning fluid storage tank, an ultrasonic generator and a filtering device, wherein the cleaning tank is arranged in the water tank body, an inlet and an outlet are arranged at two ends of the water tank body, and the conveying belt is arranged in the inlet and the outlet. With the adoption of the conveying belt, mutual collision and manual carrying of cleaning articles are avoided, the labor intensity is reduced, and the cleaning efficiency is increased; the high-pressure nozzles and the cleaning fluid storage tank are adopted for washing fruits and vegetables by the aid of water flow, the cleaning effect on the articles is improved, water recycling is realized, and energy is saved; by means of the ultrasonic generator, tiny bubbles are formed on the water surface and break instantly once meeting attachments, and the attachments on the surfaces of the articles fall off; the disinfection and sterilization functions are realized by the aid of the ozone generator, and the high-pressure disinfection and cleaning integrated machine is applicable to cleaning of the articles.

Owner:泰州市海陵区固泰标准件厂

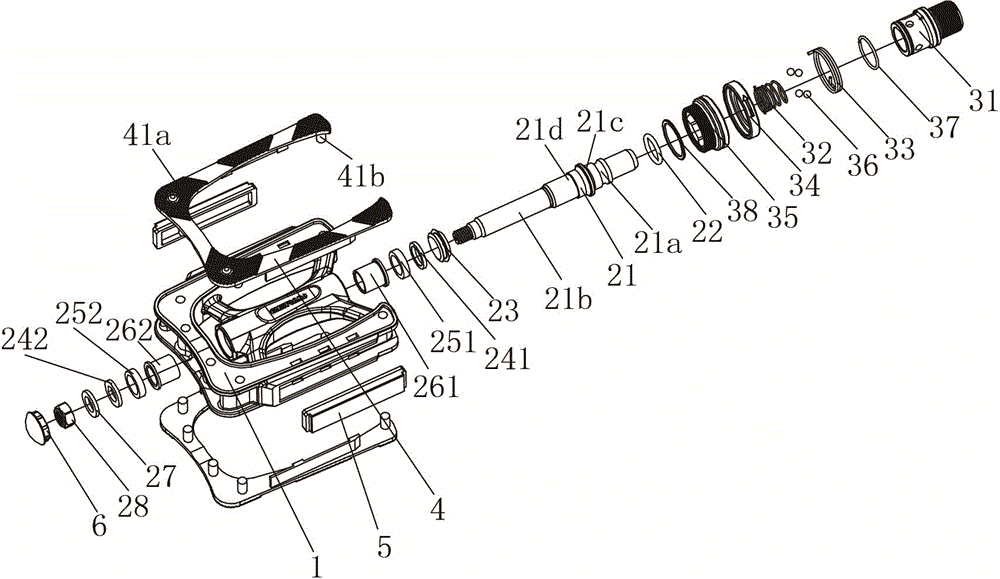

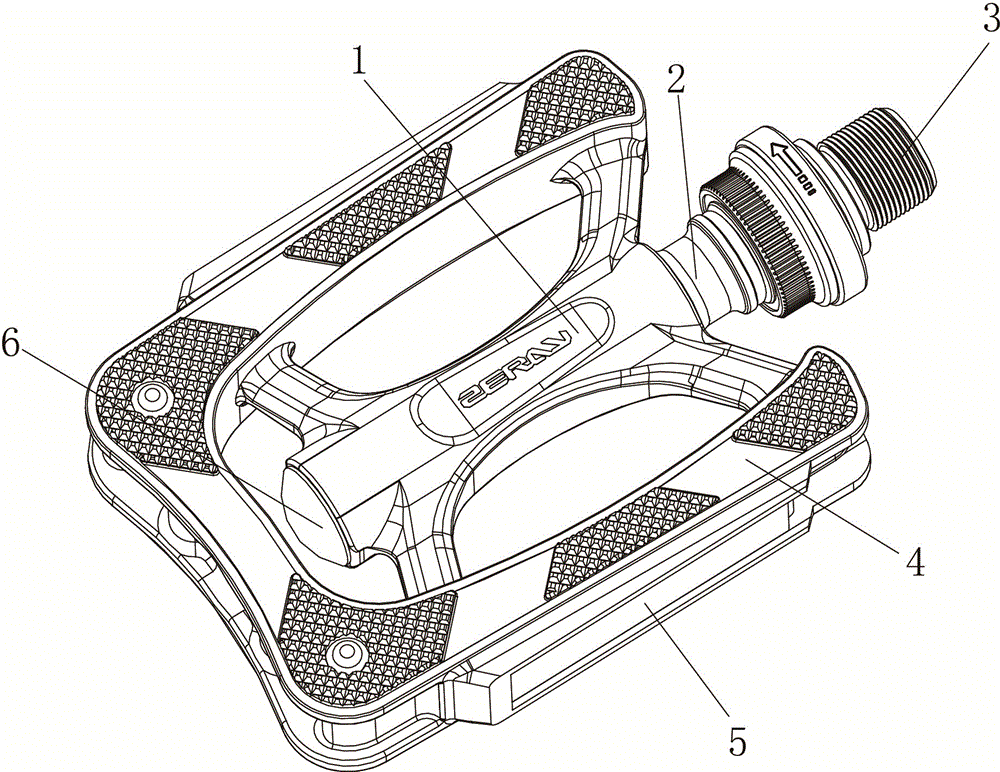

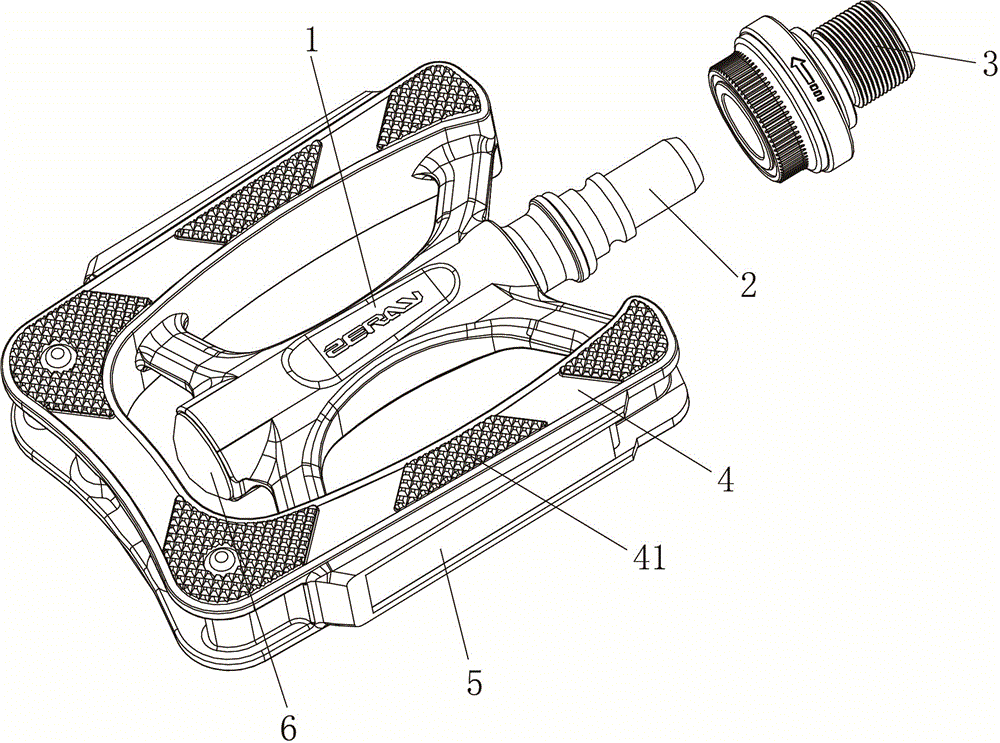

Pedal with rapidly-detachable structure

InactiveCN104139824AAchieve sheddingHigh strengthVehicle cranksMechanical engineeringMental detachment

The invention relates to a pedal with a rapidly-detachable structure. The pedal comprises a pedal body, wherein a core shaft assembly is arranged on the pedal body in a penetrating manner; a rapidly-detachable shaft head assembly is arranged on the core shaft assembly. The pedal with the rapidly-detachable structure is novel in structure and light and handy in shape; the use requirements on detachment and installation can be easily realized; and the rapidly-detachable pedal of a bicycle can be arranged and automatically popped out at any angle.

Owner:NINGBO JULONG MACHINERY CO LTD

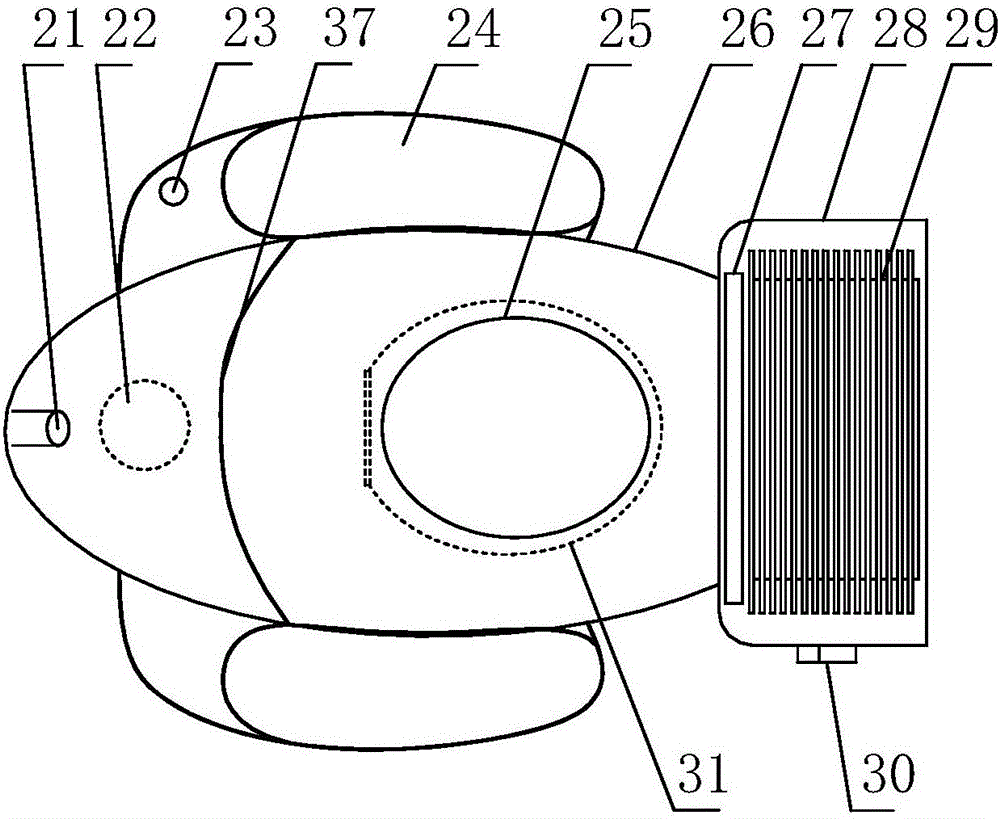

Wafer level packaging structure, method and product for LED flip chip

ActiveCN103296174AImprove light extraction efficiencyAchieve sheddingSemiconductor devicesEngineeringHeat sink

The invention discloses a wafer level packaging structure, method and product for an LED flip chip. The wafer level packaging structure comprises the LED flip chip, a silicon substrate, a lens, a printed circuit board and a heat sink. The obverse side of the silicon substrate is provided with a concave cavity in a machined mode, and the concave cavity is used for accommodating the LED flip chip. The length of the bottom of the concave cavity is identical to the length of the LED flip chip. The reverse side of the silicon substrate is provided with two through holes in a machined mode, and the two through holes are communicated with the concave cavity. Insulating layers are deposited on the surface of the concave cavity and the surfaces of the two through holes. A radiating metal layer and a reflecting metal layer are deposited on the insulating layer on the surface of the concave cavity. Metal bodies are filled in the two through holes. The metal bodies in the through holes are connected with the radiating metal layer on the surface of the concave cavity. An opening is formed between two metal layers at the inner bottom of the concave cavity and used for isolating the metal layers into two parts. An insulating layer is deposited on the reverse side of the silicon substrate, and a metal layer is arranged on the surface of the insulating layer in a wiring mode and used for electrode connection. Fluorescent powder is coated in the concave cavity. The periphery of the concave cavity is provided with an annular positioning cavity in a machined mode, and the annular positioning cavity is used for fixing the lens. The wafer level packaging structure, method and product for the LED flip chip can improve LED luminous efficiency, enhance heat dissipation capability and finish self alignment.

Owner:HUAZHONG UNIV OF SCI & TECH

Boiler decoking agent

The invention relates to a decoking agent capable of reducing and removing coke blocks and deposited ash which are positioned in a coal burning boiler and an industrial boiler. The decoking agent comprises the following components in percentage by weight: 3%-10% of potassium nitrate, 1%-5% of magnesium nitrate, 0.5%-2% of cupric nitrate, 5%-20% of ammonium sulfate, 0%-2% of picric acid and 0%-2% of borax. According to the decoking agent, an copper ion is a combustion-supporting catalyst, and can reduce the ignition point of deposited carbon and promote the sufficient combustion of coal powder; borax can crisp the coke blocks, promote the combustion of carbon contained in the coke blocks and realize the falling of the coke blocks; the nitrate is an oxidizing agent, can release oxygen for combustion support under the condition of high temperature and can clean coke and the deposited ash by synergically generating explosion effect with picric acid. The decoking agent disclosed by the invention has the advantages of low cost and easiness for obtaining of raw materials, simple preparation process and convenience for use without causing any corrosion or generating any secondary pollution on the boilers.

Owner:聂冰晶 +1

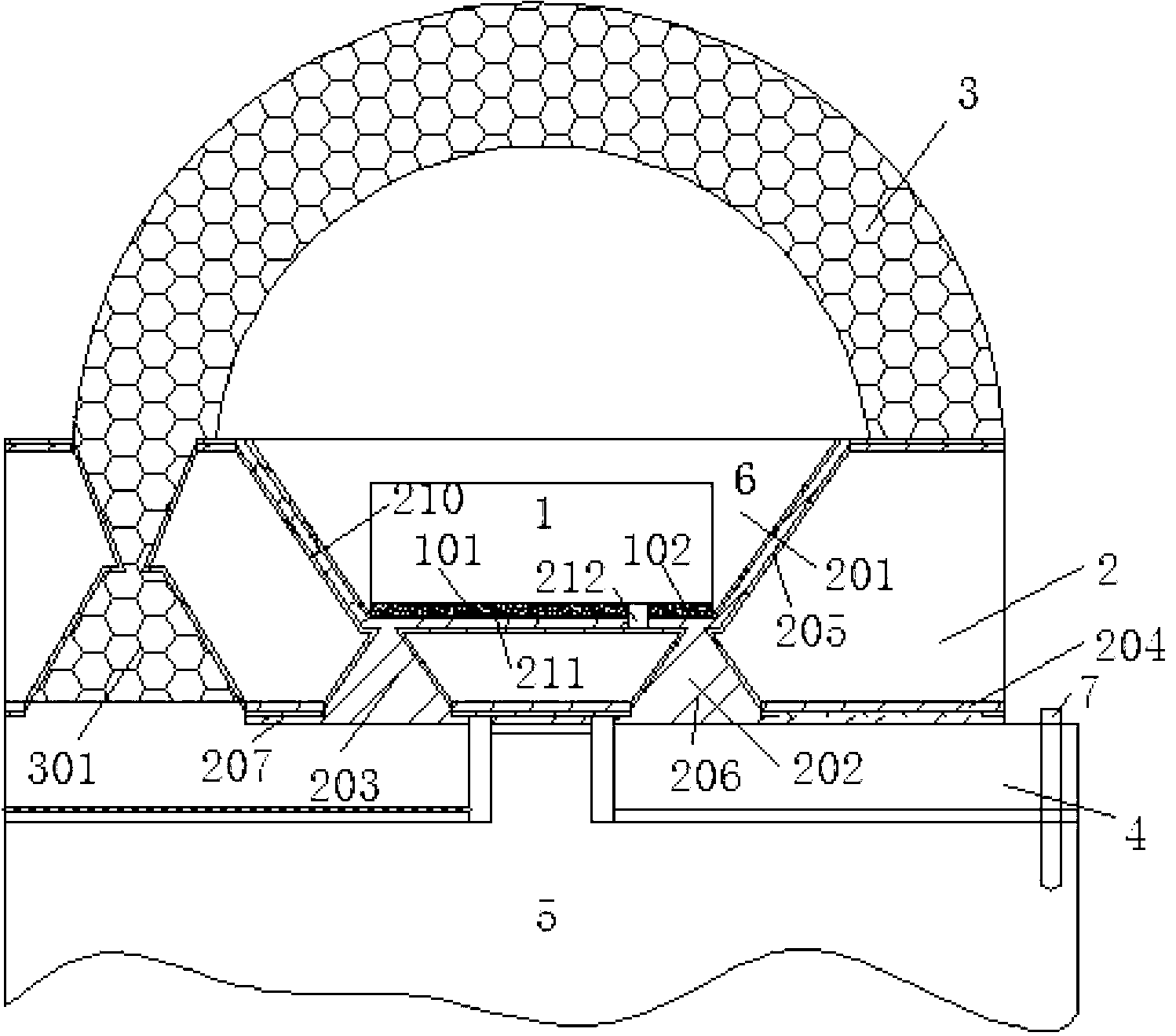

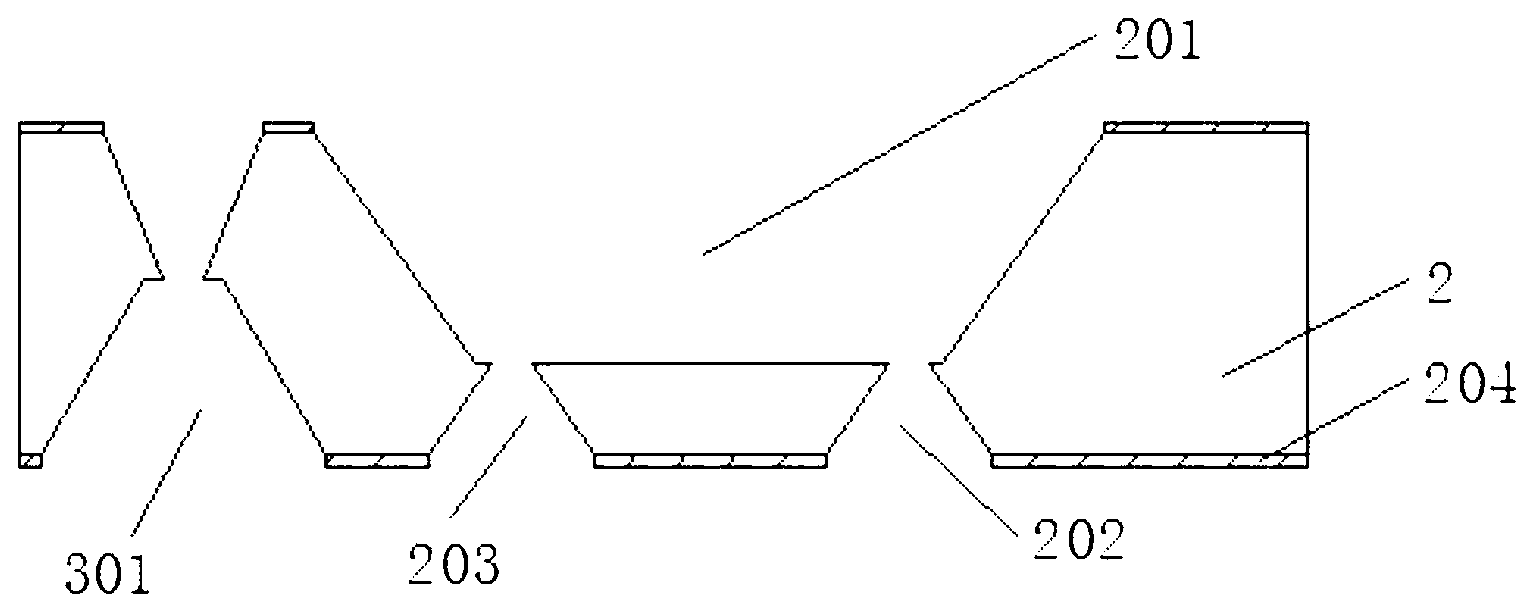

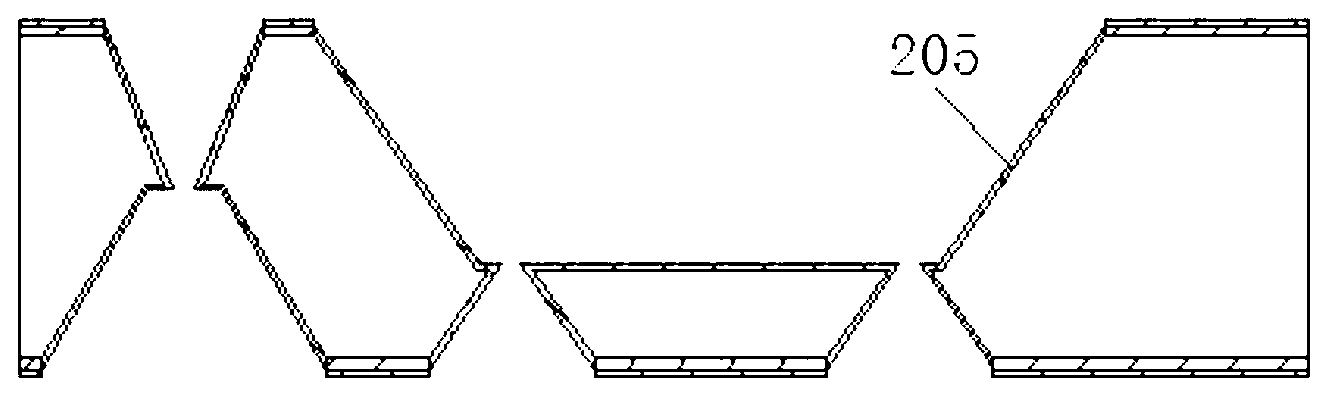

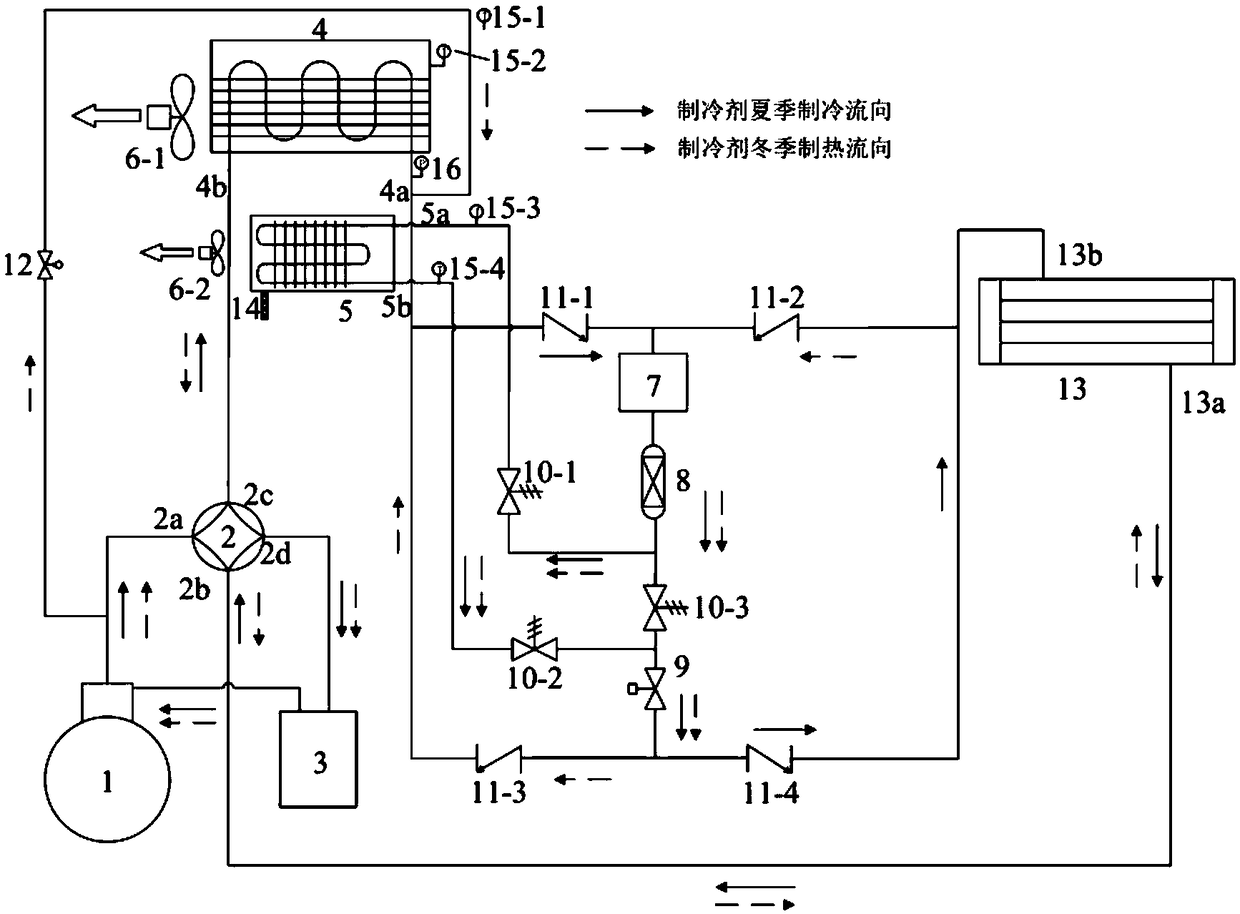

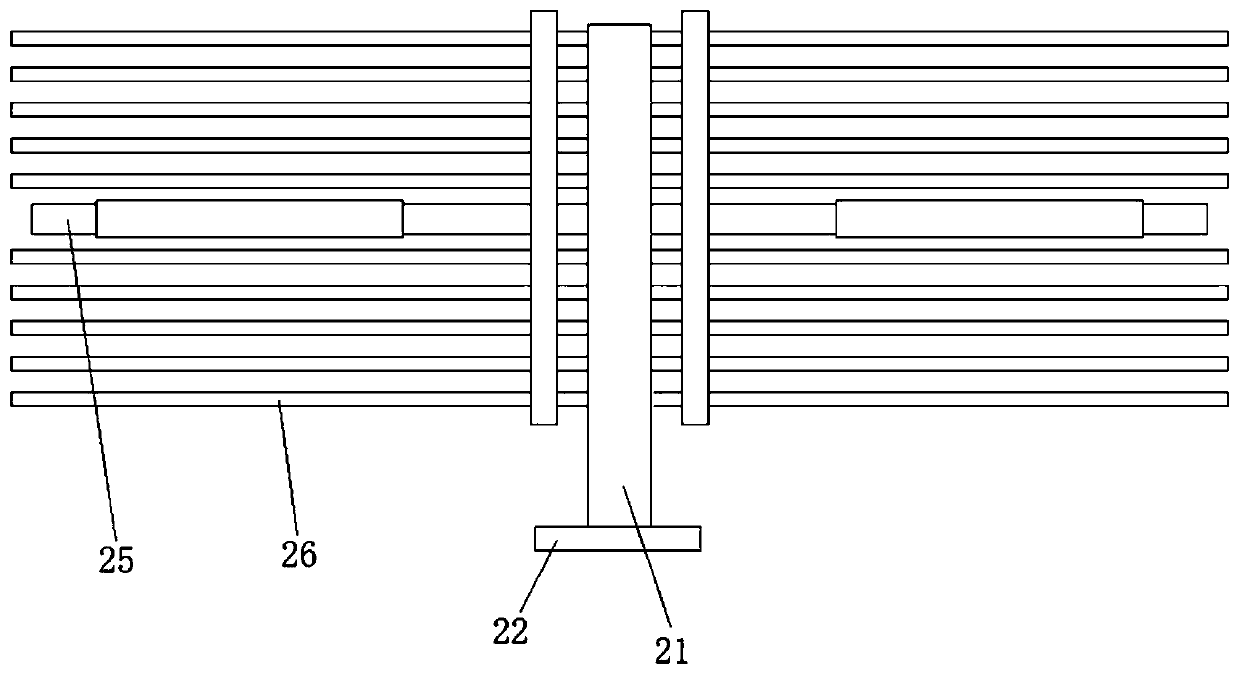

Superhydrophobic fin type heat exchanger based air source heat pump with detached defrosting device and working method thereof

ActiveCN109469990AShedding achievedReduce adhesionMechanical apparatusCorrosion preventionVapor–liquid separatorFrost

The invention discloses a superhydrophobic fin type heat exchanger based air source heat pump with a detached defrosting device and a working method thereof. The air source heat pump comprises a gas-liquid separator, a compressor, a four-way commutator, a first heat exchanger, a second heat exchanger, a first fan, a liquid storing branch circuit, a defrosting water loop and a defrosting refrigerating agent conveying branch circuit; the defrosting water loop comprises a defrosting device, a first electromagnetic valve and a second electromagnetic valve; the defrosting refrigerating agent conveying branch circuit is installed between the refrigerating agent output end of the compressor and the first heat exchanger, and an electric regulating valve is installed on the defrosting refrigeratingagent conveying branch circuit; the defrosting device is located under the first heat exchanger, and frost layers condensed on the surfaces of fins of the first heat exchanger can exactly fall to thedefrosting device; and the heat, for melting the frost layers, of the defrosting device is from the heat released through supercooling of a refrigerating agent output by a refrigerating agent conveying flow channel arranged on the inner side of the second heat exchanger. According to the superhydrophobic fin type heat exchanger based air source heat pump with the detached defrosting device and the working method thereof, the frost layers on the surfaces of the fins overall fall off in the defrosting process, the defrosting time is significantly shortened, and defrosting energy consumption canbe effectively reduced.

Owner:SOUTHEAST UNIV

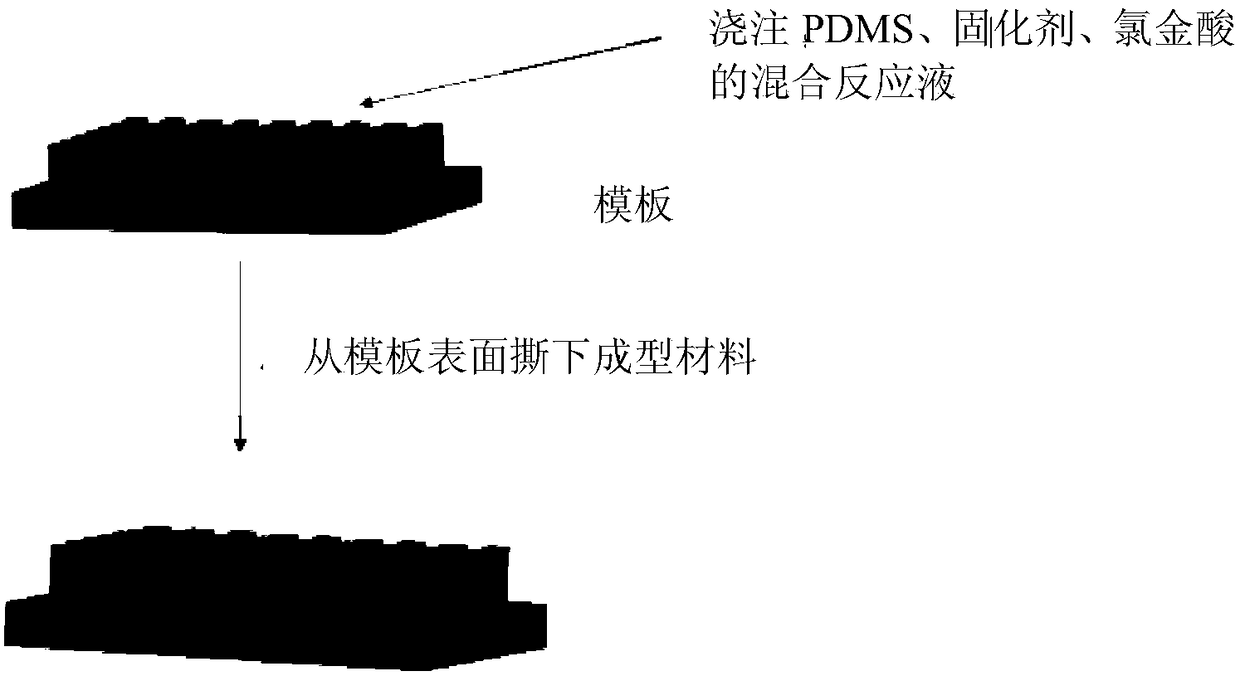

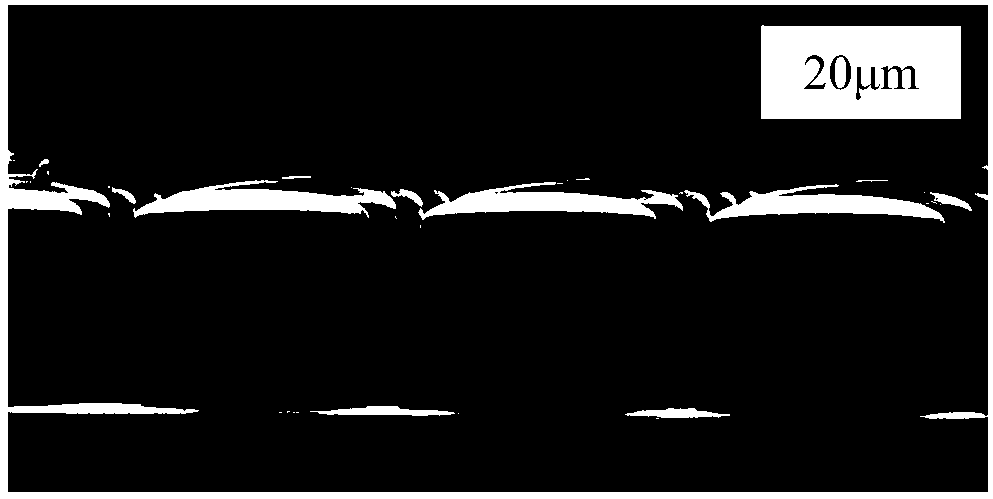

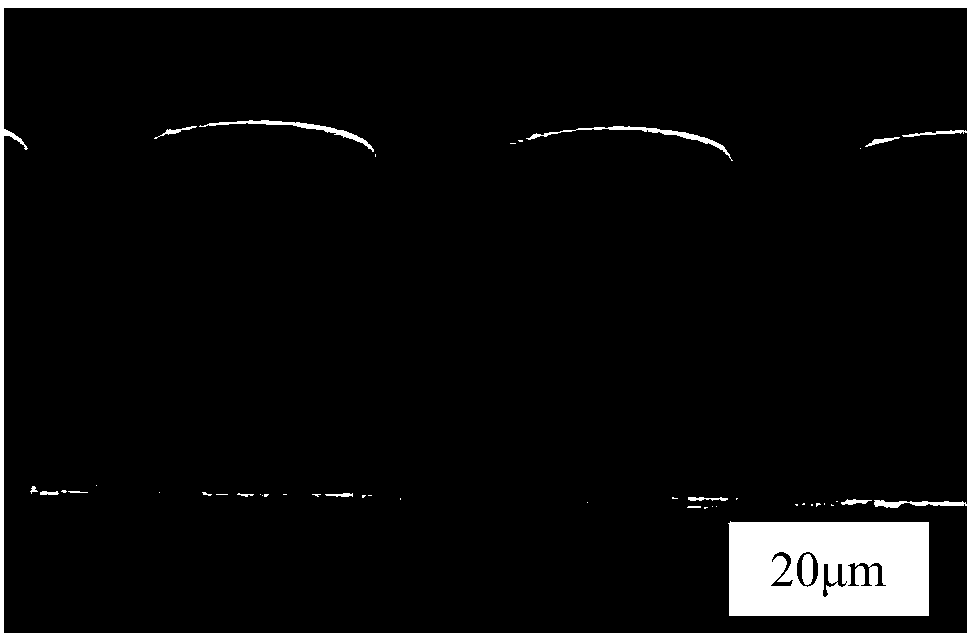

Biomimetic material as well as preparation method and application thereof

The invention provides a biomimetic material as well as a preparation method and application thereof. The biomimetic material is prepared by the following method with the steps that high-molecular polymers are sufficiently mixed with excessive reductive curing agents; then, a noble metal salt water solution is added, so that noble metal salts and the excessive reductive curing agents react to obtain nanometer form noble metal; then, drying curing is performed to obtain the biomimetic material. The biomimetic material has various good properties, such as high viscosity, repeated use performanceand high conductivity, and can be applied to various technical fields such as the technical fields of microfluidics.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

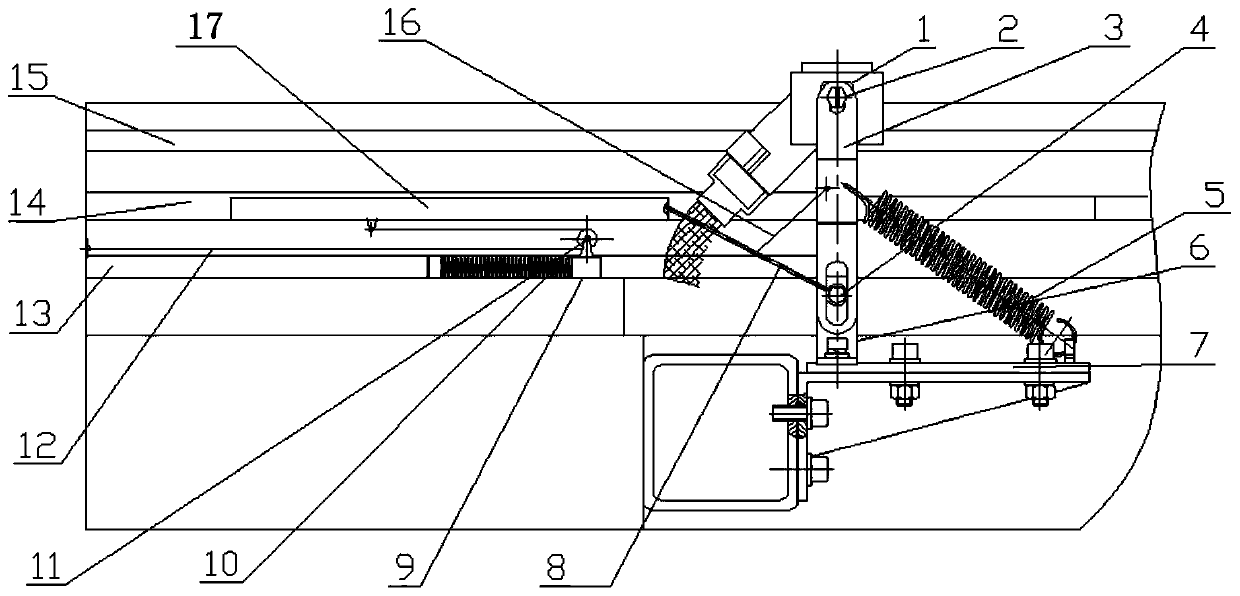

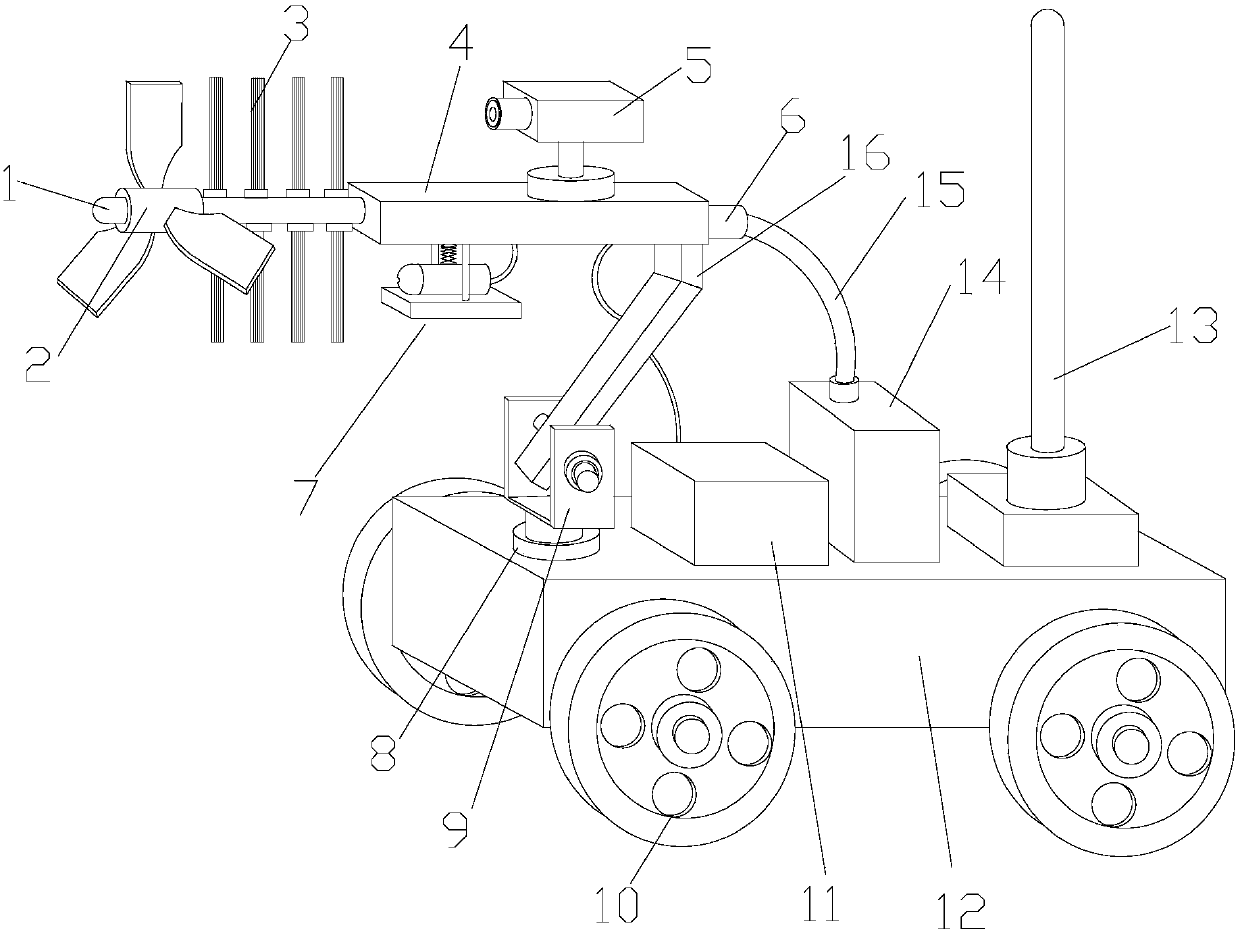

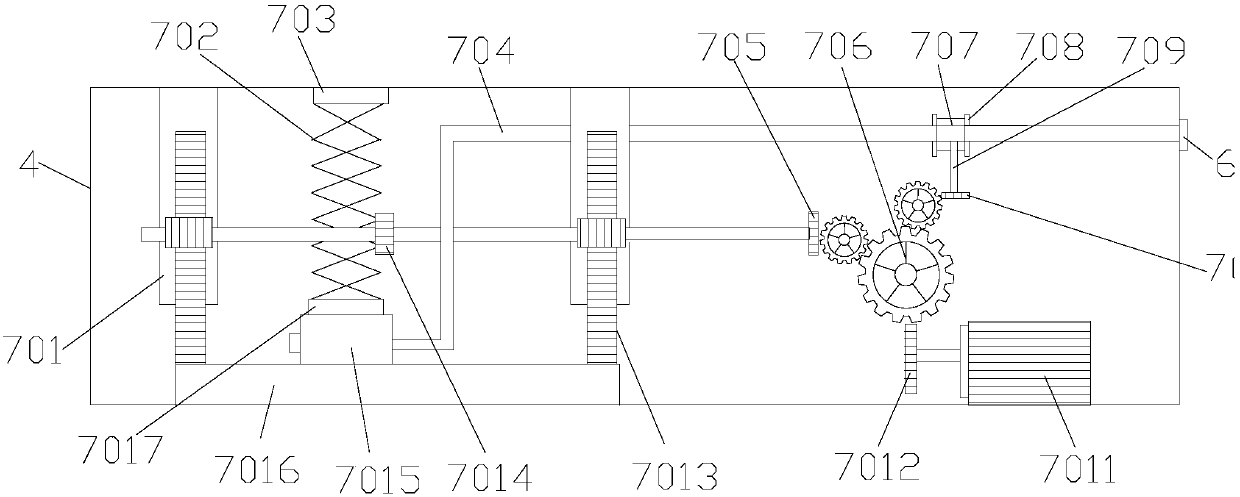

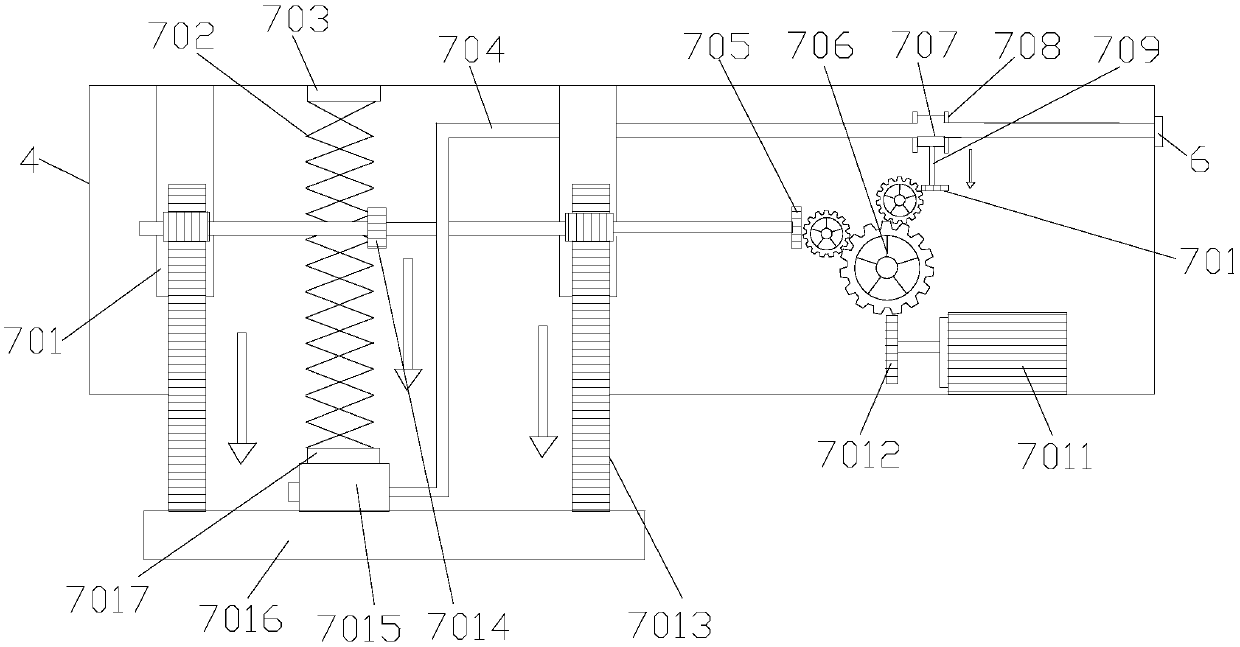

Clearing machine for residential housing water supplying and draining ditch wall automatic clearing equipment

InactiveCN107724450AAchieve sheddingImprove work efficiencySoil-shifting machines/dredgersDrive wheelSurveillance camera

The invention discloses a cleaning machine for automatic equipment for cleaning water supply and drainage ditch walls of houses and residences. Seat, movable frame, driving wheel, power control box, driving seat, wireless signal receiving mechanism, water storage tank, water supply pipe, movable arm, the present invention realizes the cleaning of the water supply and drainage ditch wall of the house by providing an automatic cleaning device The automation equipment can automatically clean up the moss and other attached aquatic organisms stuck to the equipment during the working process, thereby improving the working efficiency of the equipment and having strong practicability.

Owner:倪其棍

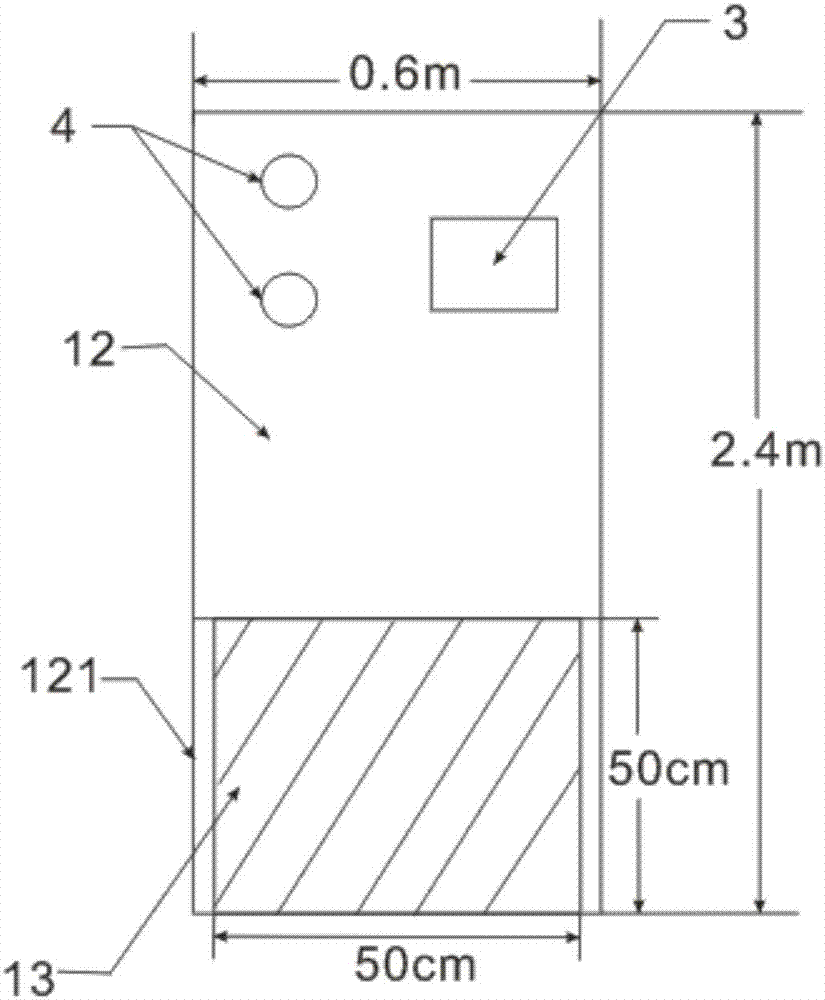

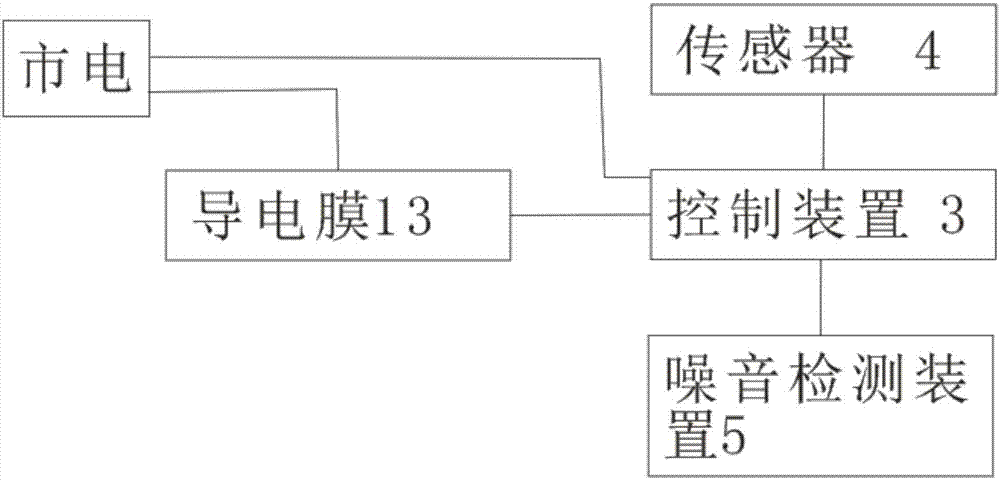

Internal wall heat-insulation fireproof functional wallboard with electro-thermal film

PendingCN107268831AFlame retardant hasWaterproofLighting and heating apparatusWallsTemperature controlEngineering

The invention discloses an internal wall heat-insulation fireproof functional wallboard with an electro-thermal film. The wallboard comprises an inner wallboard body and a facing material, wherein the inner wallboard body is a composite plate and comprises a heat-insulation flame-retardant plate and a base plate, the heat-insulation flame-retardant plate and the base plate are adhered together through an adhesive layer, a conductive area is arranged on the base plate, and the conductive area is covered with the electro-thermal film; the surfaces of the base plate and the conductive area are coated with the facing material, and the electro-thermal film is electrified to generate heat. By means of the structure, heat and cold of a wall can be effectively prevented from invading indoors, and the temperature of the indoor environment is kept normal; meanwhile, the electro-thermal film is arranged on the base plate and has a heating function, the functional wallboard capable of achieving automatic heating and intelligent temperature control is formed, the indoor temperature is effectively adjusted, and the energy consumption is greatly reduced; the heating area is large, and the functional wallboard has excellent heat insulation, waterproof and dehumidifying functions, so that the heat is not absorbed by the wall and is released outdoors, a constant comfortable temperature is kept in a room, and the room is particularly suitable for babies or elder people to live in.

Owner:深圳市廷宏科技有限公司

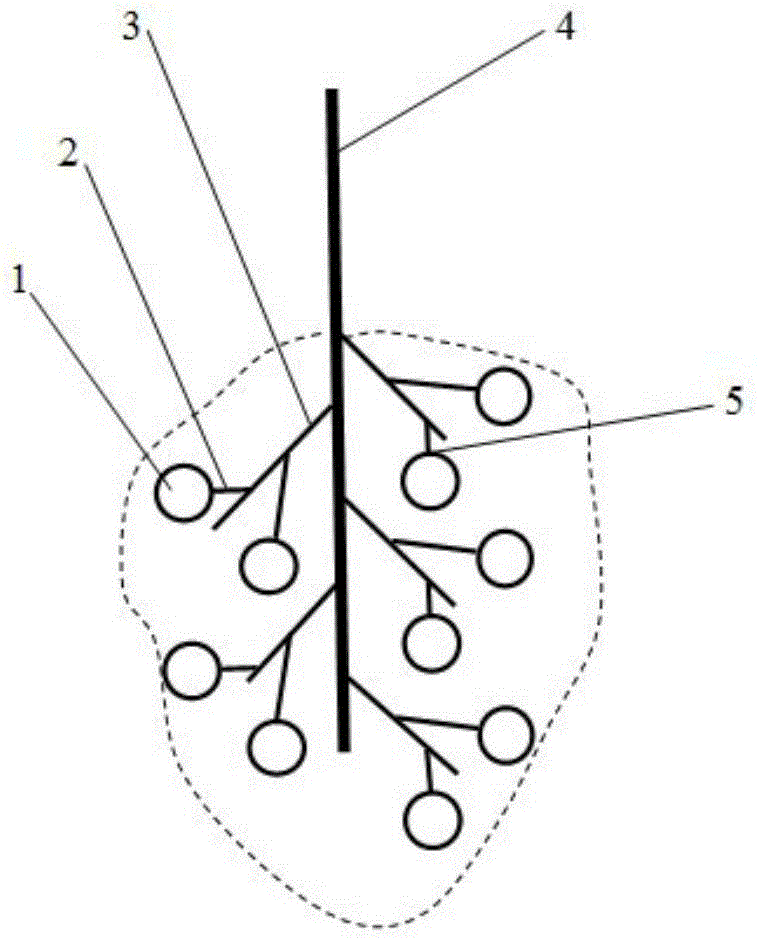

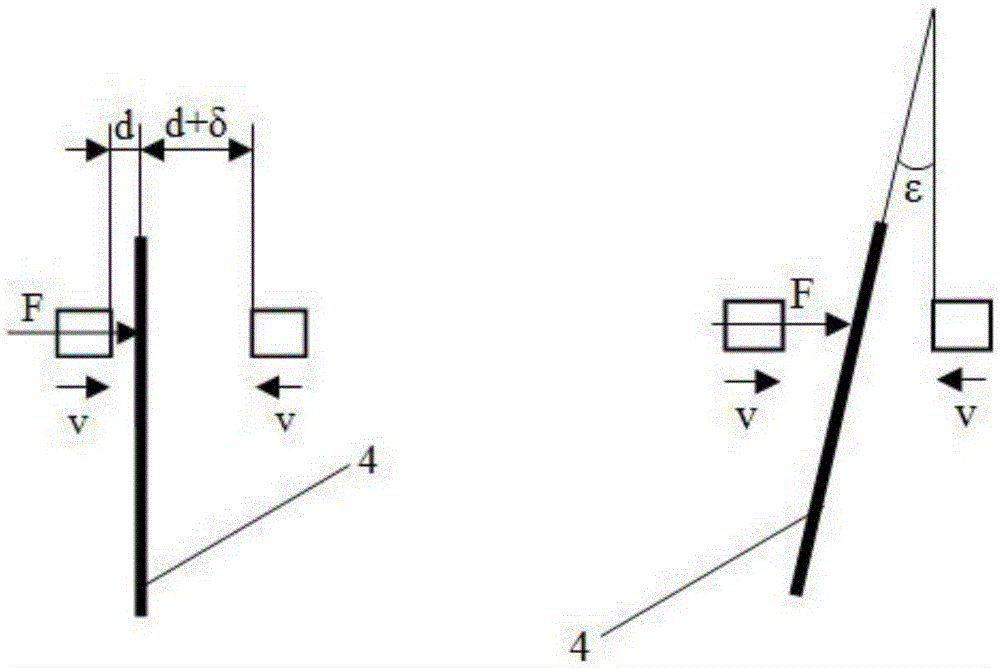

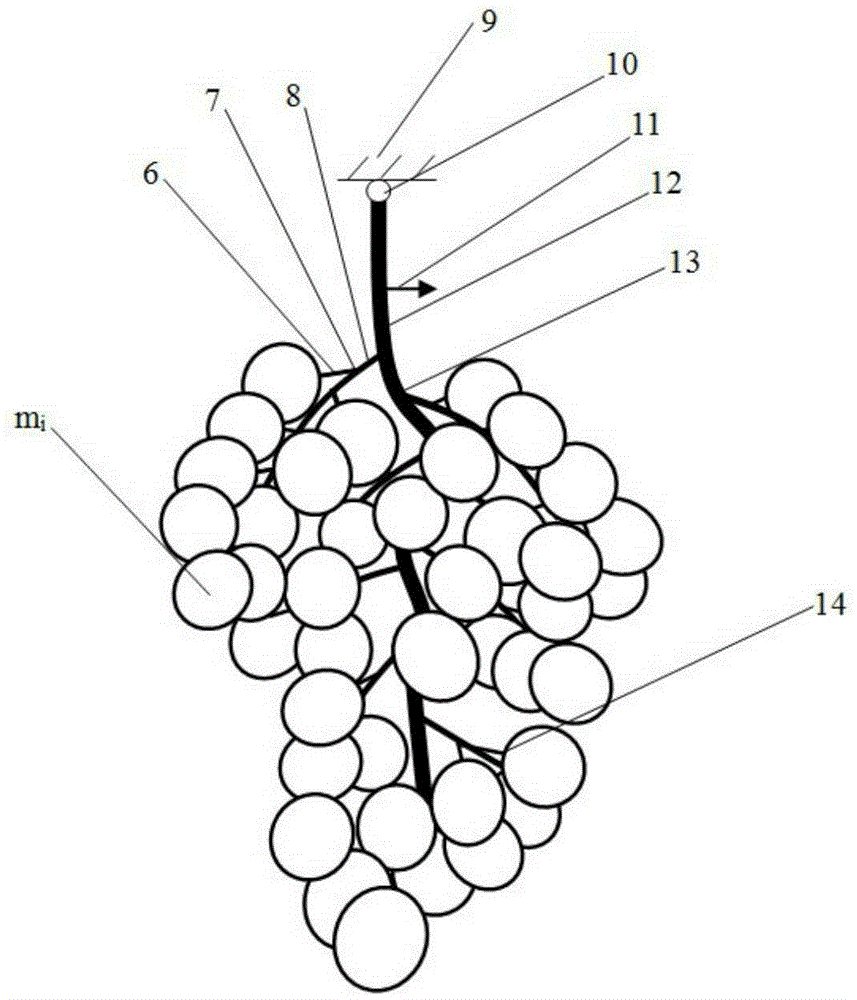

Cluster vibration fall-off simulation model and establishment method thereof

InactiveCN105320821AImplement incentive transferAchieve swingSpecial data processing applicationsLaser scanningPhases of clinical research

The invention discloses a cluster vibration fall-off simulation model and an establishment method thereof, and relates to the field of agriculture devices and simulation analysis. A cluster system entity model is obtained through the combination of laser scanning and entity modeling, a main cluster shaft is represented by a flexible rod, branch cluster shafts are represented by class-I rigid rods, fruit stems are represented by class-II rigid rods, and all fruits are represented by mass balls. Normal distribution laws of connection of the flexible rod, the mass balls and entities are obtained according to physical and mechanical characteristic tests of large samples, and different main cluster shaft restraining and stimulation openings of the picking and transferring stages are added, and the cluster vibration fall-off simulation model is established. Cluster characteristics under large individual differences are effectively reflected, simulation analysis of stimulation transferring and fruit swinging and fall-off of complex cluster systems is achieved, and foundation is provided for structure optimization and control optimization of robots.

Owner:JIANGSU UNIV

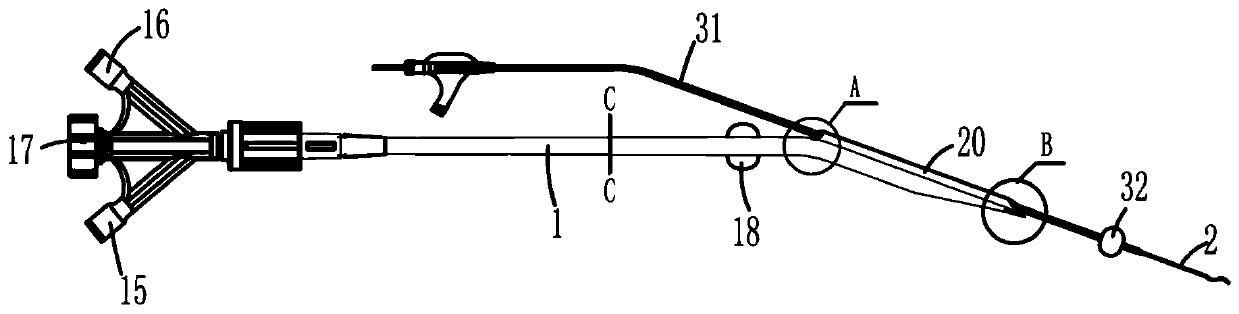

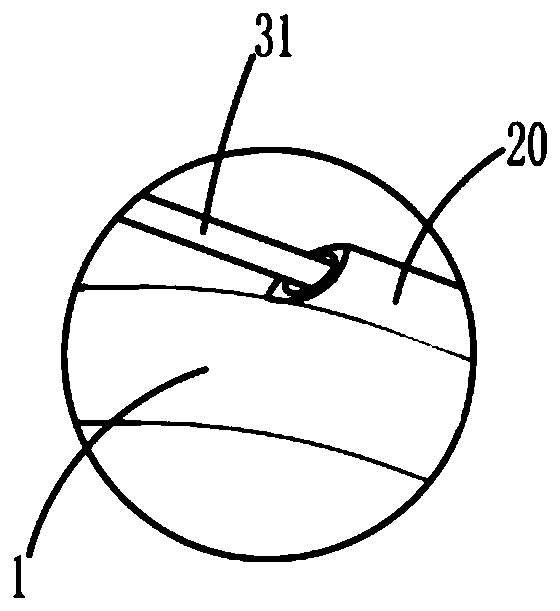

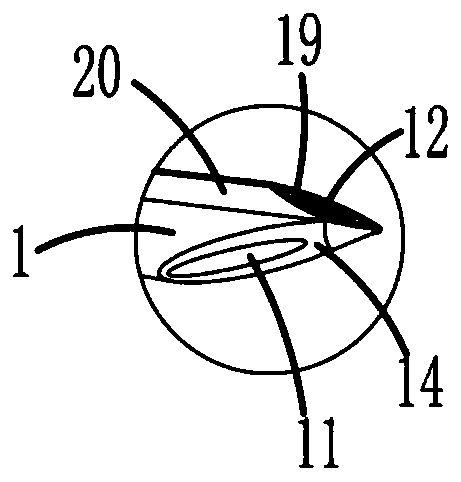

Thrombus treatment system

The invention relates to a thrombus treatment system which comprises a first catheter, a second catheter, a plugging device and a stirring device, the first catheter is provided with a first channel,the second catheter is provided with a second channel, the plugging device comprises a third catheter and a plugging device which is arranged at the far end of the third catheter and has an open stateand a closed state, the stirring device comprises a first sheathing canal, a second sheathing canal arranged outside the first sheathing canal in a sliding and sleeving mode and a stirring assembly arranged at the far end of the first sheathing canal. A large amount of thrombus in the inferior vena cava can be removed under the condition that relative safety is guaranteed, the venous valve and the venous vessel wall are protected, the blood loss amount is controllable, the operation steps are simple, operation is more convenient, the operation time can be shortened, and the hospitalization cost of a patient is reduced.

Owner:SUZHOU TIANHONGSHENGJIE MEDICAL INSTR CO LTD

Novel shell-breaking device for gordon euryale

The invention discloses a novel shell-breaking device for gordon euryale, and is characterized in that the lower left part of a rotary drum is arranged in a fruit box in an immerged manner, and the rotary drum is supported on a frame by a right drum shaft and a left drum shaft, and a number of suction holes are evenly distributed in the same circumferential wall in the radial direction and are fixedly connected with the corresponding number of gordon euryale taking devices; a left cylinder and a right cylinder are fixedly connected on the frame; the front end of an expansion rod of each cylinder is fixedly connected with a press plate, so as to make the expansion rods of the two cylinders extend at the same time, drive a left extrusion plate and a right extrusion plate to move towards thecenter, reduce the distance between the two press plates, and extrude gordon euryale in the gordon euryale taking devices so as to achieve shell breaking. Mechanized shell breaking of gordon euryale seeds is achieved, the labor intensity of workers is greatly reduced, and the production efficiency is improved.

Owner:SICHUAN AGRI UNIV

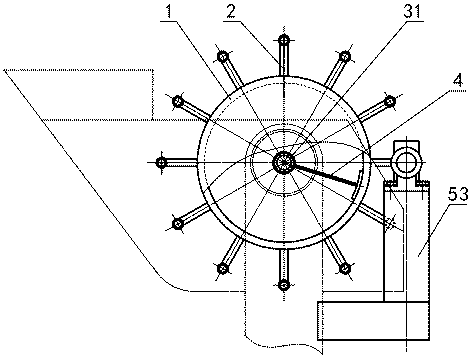

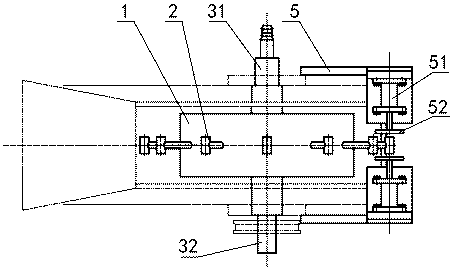

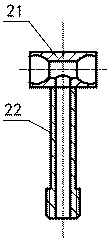

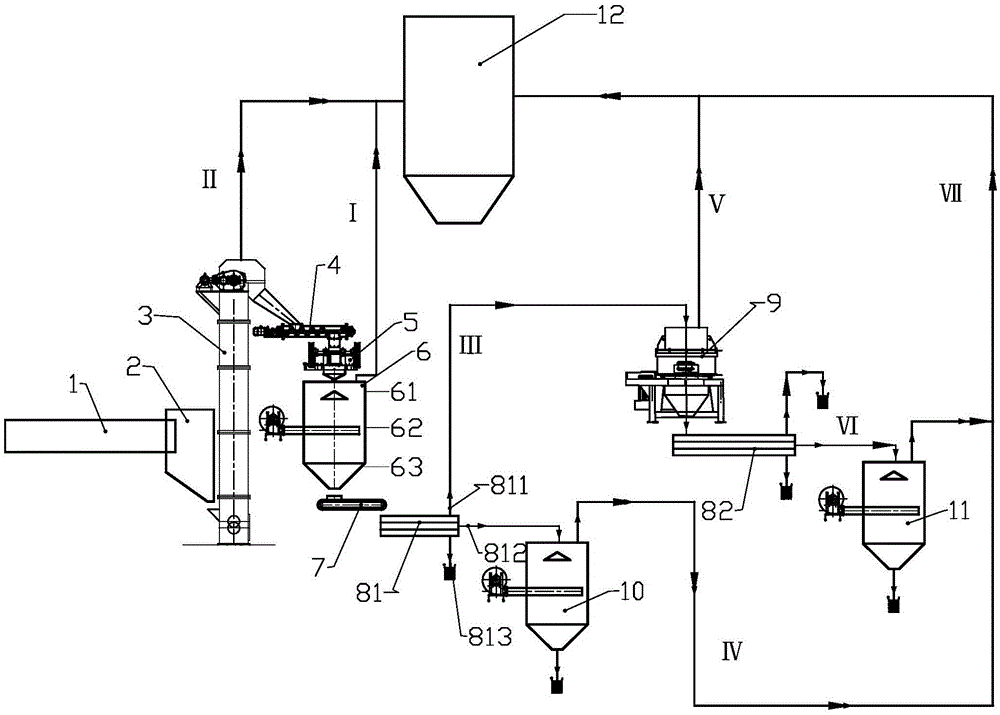

Processing system for kiln tail ceramsite caking materials

ActiveCN105562188AImprove surface conditionAchieve separationGrain treatmentsExpanded clay aggregateProcess engineering

The invention discloses a processing system for kiln tail ceramsite caking materials. The processing system comprises a feeding device, a material lifting device, a spiral extrusion feeder, a cage-type crusher, a first-level particle separating subsystem, a second-level crushing and separating subsystem and a dust removing subsystem which are connected in sequence. The first-level particle separating subsystem comprises three sets of separating equipment. The first swinging screen equipment is of a double-layer screen cloth structure. Second swinging screen equipment is of a double-layer screen cloth structure. The dust removing subsystem is simultaneously connected with the first-level particle separating subsystem, an impact-type crusher, the second separating equipment and third separating equipment through a pipeline. According to the processing system for the kiln tail ceramsite caking materials, the method of combining the spiral extrusion feeder with the cage-type crusher is adopted, and the proportion of bonding aggregates in the screened materials is decreased; meanwhile, pre-shaping processing is conducted on all particles, and thus the surface states of the particles are improved.

Owner:山东谊星新材料有限公司

Injection moulding method using cold-hot flow passage

The invention relates to a method of injection molding by adopting hot runners and cold runners, which is characterized in that the upper end of each cold runner of a former die for injection molding is additionally provided with a transition runner outside which a transition sleeve and a degumming sleeve are arranged; the upper end of each transition runner is connected with a hot runner containing liquid for injection molding in a molten state; materials for injection molding in the hot runner are heated to 260 to 300 DEG C to ensure that the liquid for injection molding is kept in a molten state; an injection molding machine is then started to cause the molten liquid in the hot runner to be conveyed to the transition runner and then to be separately conveyed to the multipoint cold runner to conduct the multipoint casting so as to complete the injection molding of products. The method of injection molding of the invention has the advantages of controlling sprue wastes in a minimum production amount, ensuring the economic production, reducing the pressure of injection molding and prolonging the service life of the dies.

Owner:SHANGHAI YAHONG MOLDING

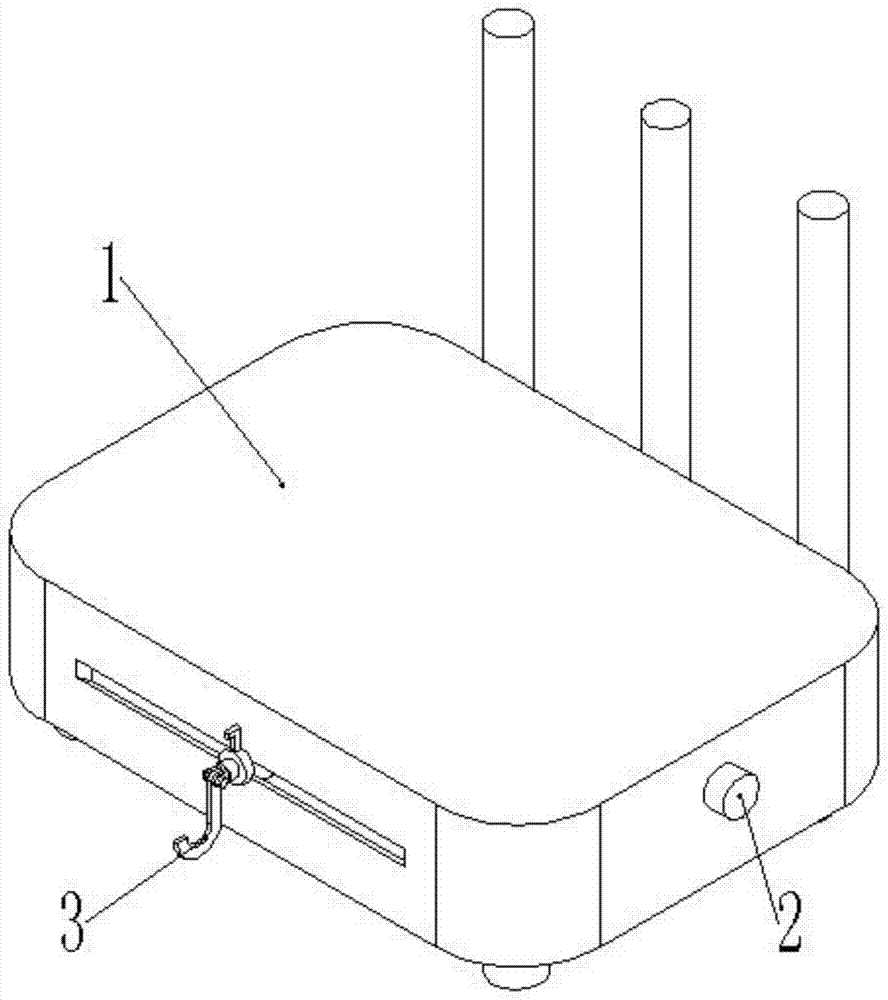

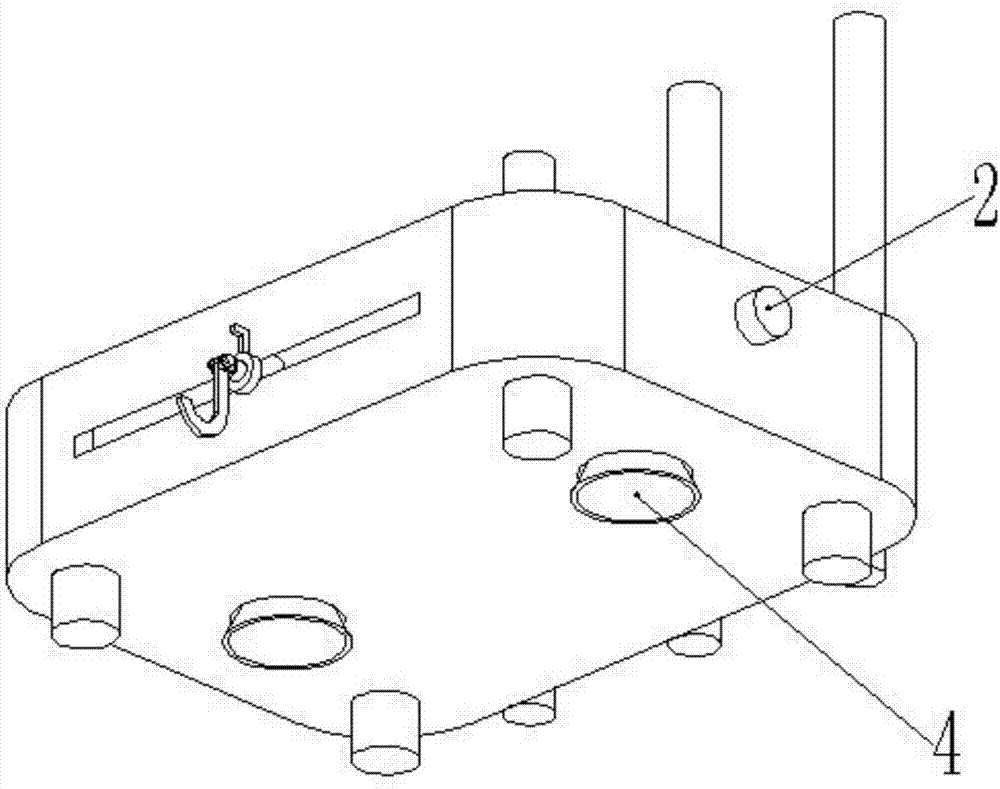

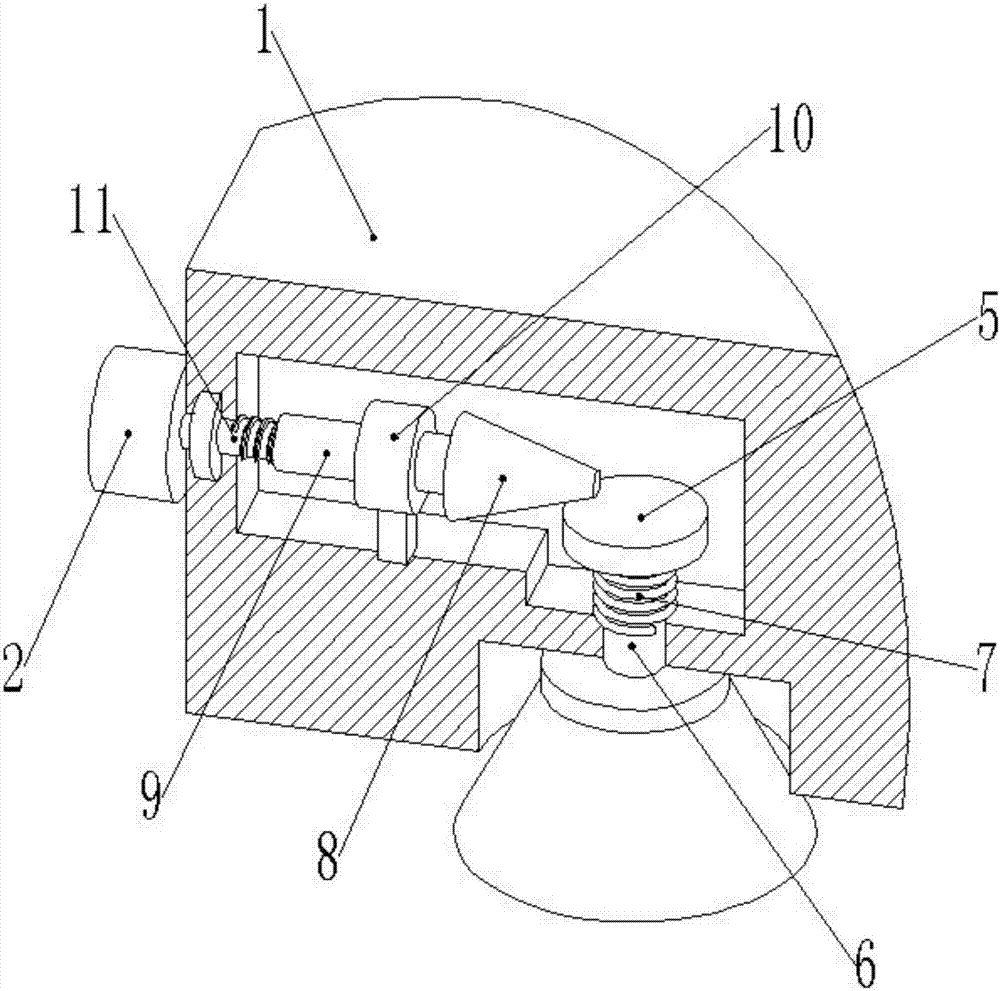

Wireless router convenient to fix and hang

InactiveCN108011830AImprove stabilityAchieve suspensionData switching networksSelection arrangementsWireless routerEngineering

The invention relates to the related technical field of routers, and in particular relates to a wireless router convenient to fix and hang. A placement groove is formed in the router; a support base is arranged in the placement groove; a sleeve is rotatably in sleeved connection on the support base; a screw is in threaded connection in the sleeve; one end of the screw is rotatably in sleeved connection in the router, and fixedly connected with a first knob; a tip cone is fixedly connected onto the sleeve; a baffle is arranged below the tip cone; a connecting rod is fixedly connected below thebaffle; suction cups are arranged below the connecting rod; a spring is in sleeved connection on the connecting rod; a sliding groove is formed at the front side of the router; a sliding block is arranged in the sliding groove; a first screw shaft is fixedly connected onto the sliding block; the first screw shaft is in threaded connection with a nut; a shifting rod is arranged on the side surfaceof the nut; two frame plates are arranged on the first screw shaft, wherein the frame plate at the left side is provided with a threaded hole; the frame plate at the right side and a hook are providedwith a through hole; a second screw shaft passes through the through hole, and is in threaded connection with the threaded hole; one end of the second screw shaft is fixedly connected with a second knob; and the other end of the second screw shaft is fixedly connected to a limiting plate.

Owner:NORTH CHINA INST OF SCI & TECH

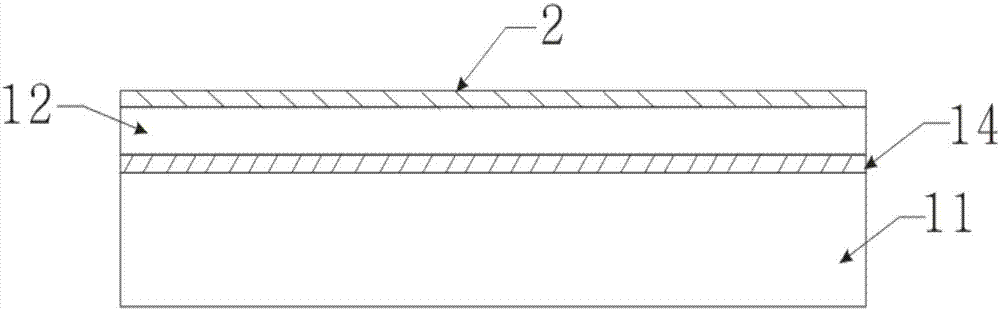

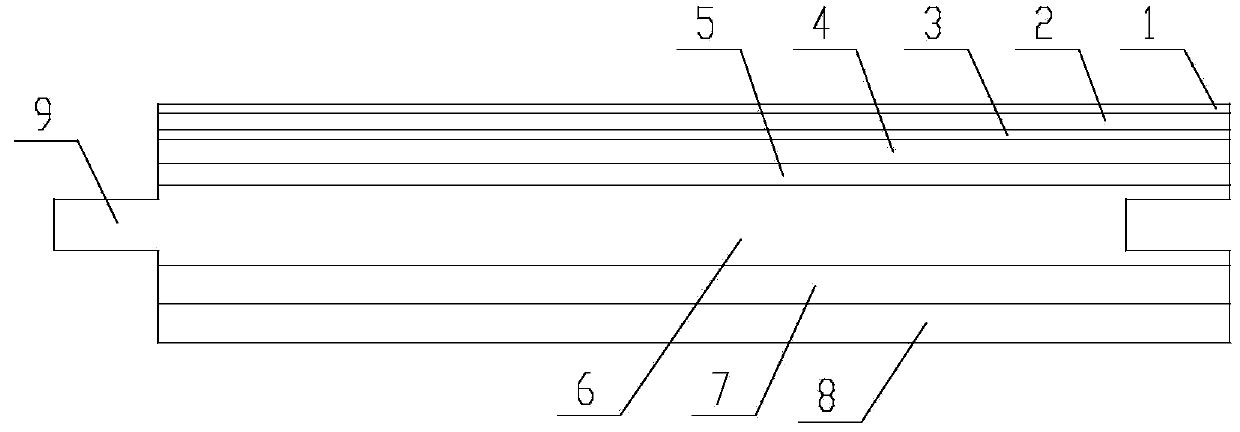

Fireproof waterproof and environmental-friendly floor

InactiveCN103790328AStable materialNot easy to shrinkSynthetic resin layered productsWood layered productsCement boardEnvironmentally friendly

The invention relates to a fireproof waterproof and environmental-friendly floor. The environmental-friendly floor is of a multi-layer structure and comprises a UV resin layer, anti-abrasion paper, melamine paper, a fireproof wood veneer, a first cement board, a multi-layer wood veneer pressboard, a second cement board and a polyvinyl ethyl layer, wherein the UV resin layer, the anti-abrasion paper, the melamine paper, the fireproof wood veneer, the first cement board, the multi-layer wood veneer pressboard, the second cement board and the polyvinyl ethyl layer are arranged in parallel from top to bottom, and connecting parts are arranged on the two sides of the multi-layer wood veneer pressboard and matched mutually. The fireproof grade of the fireproof waterproof and environmental-friendly floor can reach the B1 grade, the floor does not crack when soaked in water within 120 h, paint-free fire prevention and falling prevention are achieved, the floor contains no harmful substance and is ecological and environmentally friendly, and patterns are formed on the melamine paper after hot pressing, so that the floor has a decorative effect and is suitable for indoor decoration. In addition, the materials are stable and not prone to expanding, shrinking or deforming; the floor is high in surface hardness and abrasion resistance; the fancy is various, the decoration is rich and colorful, product speed is high, and manufacturing cost is low, so that popularization is facilitated; not only can use requirements of people be met, but also forest resources can be protected, and the environment is protected.

Owner:张家港市柏林新型材料科技有限公司

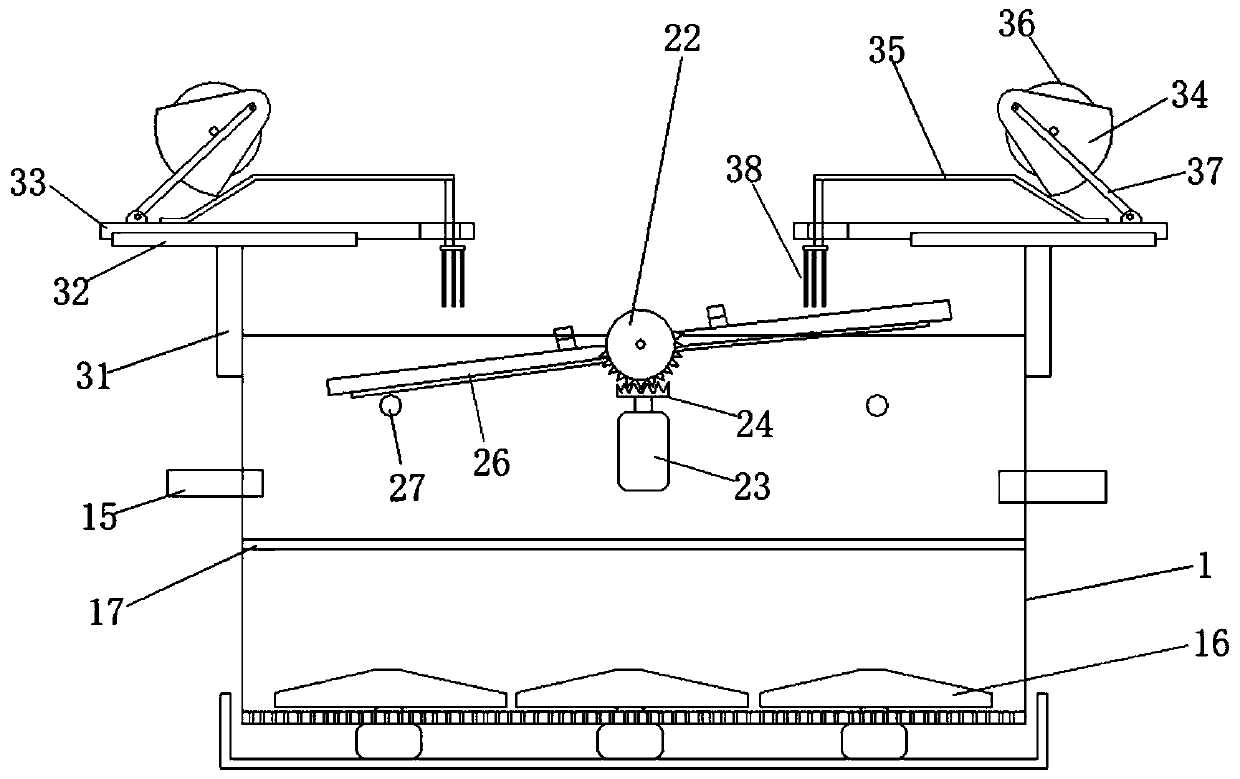

Capsule extraction mechanism and capsule coffee machine

PendingCN109662581AAchieve sheddingRealize the function of dropping packetsBeverage vesselsBiomedical engineering

The invention relates to a capsule extraction mechanism and a capsule coffee machine, wherein the capsule extraction mechanism comprises a capsule outer cavity, a capsule inner cavity arranged in thecapsule outer cavity and a bayonet disc; the bayonet disc is arranged on the capsule inner cavity and is used for puncturing a capsule arranged in the capsule inner cavity; the capsule inner cavity comprises an inner cavity main body and at least two cavity petals arranged in the inner cavity main body, and the cavity petals are enclosed to form a capsule accommodating space; the cavity petals canmove relative to the cavity body to extend out of the inner cavity body, and when the cavity petals extend out of the inner cavity body, the cavity petals are relatively expanded. According to the capsule extraction mechanism, the capsule contained in the capsule accommodating space can be dropped off through the relative opening of the cavity petals, so that the capsule dropping function is achieved, and the capsule extraction mechanism is suitable for capsules prepared from degradable materials.

Owner:NINGBO JIAYIN ELECTRICAL & MECHANICAL TECH CO LTD

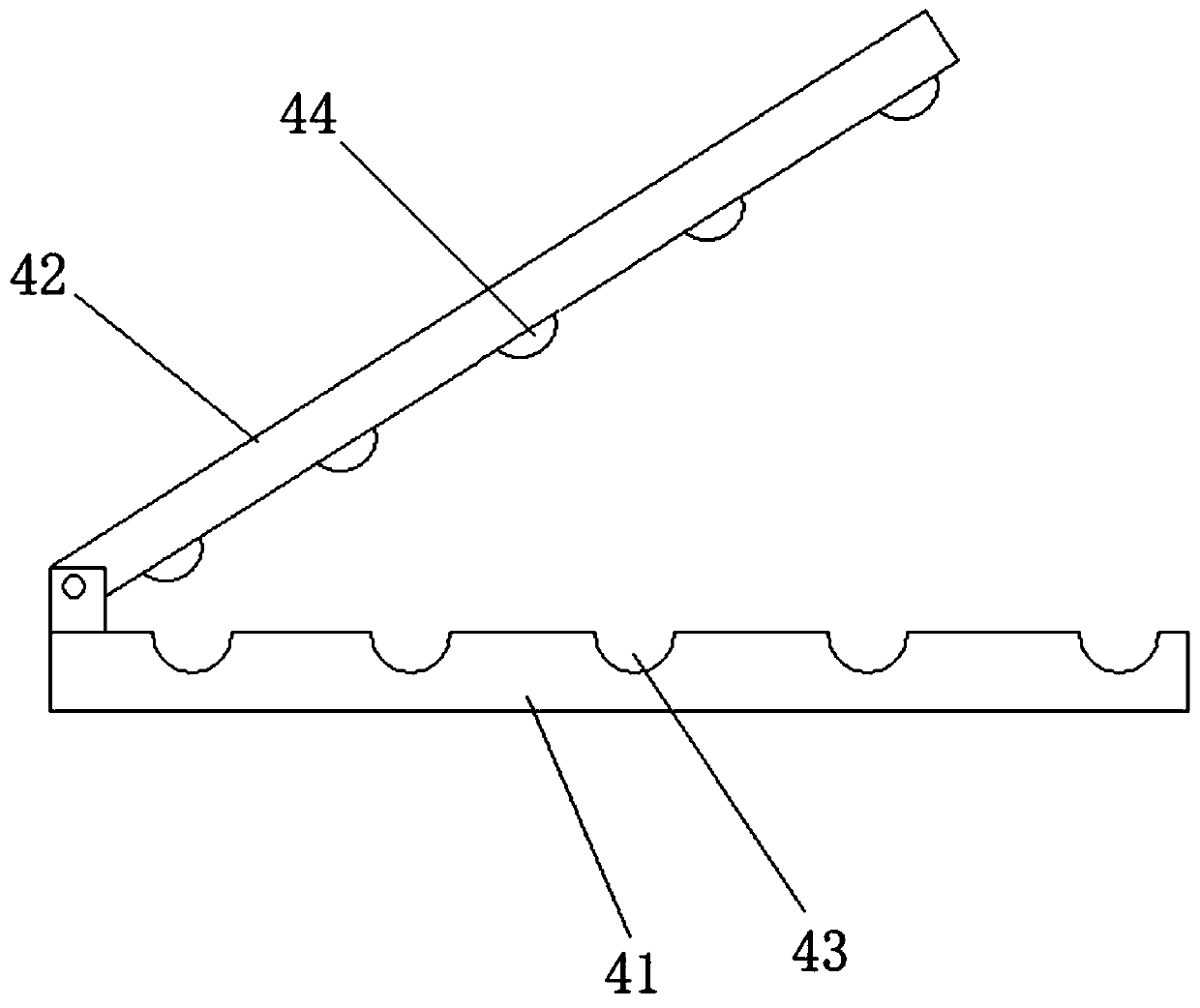

Peanut fruit and root hair separating device and working method thereof

ActiveCN111213474ASo as not to damageCause damageDigger harvestersAgricultural engineeringElectric machinery

The invention discloses a peanut fruit and root hair separating device and a working method thereof. The peanut fruit and root hair separating device includes a peanut beating mechanism, a peanut combing mechanism, and a storage bin; the peanut beating mechanism includes a roller shaft, a stepping motor, an impact rod, and a plurality of load-bearing rods, the stepping motor drives the roller shaft to reciprocate, a limiting bar is arranged between a pair of side walls of the storage bin, and a cushion pad is in contact with the limiting bar along with the impact bar; and the peanut combing mechanism includes a bracket structure, a fixed bottom plate, a sliding plate, a cam, a press sheet and a fixed motor, and the fixed motor drives the press sheet to intermittently clears residual peanuts. Through the automatic design, manual operation is reduced, and the separation efficiency of peanuts is high, omission nor damage to peanuts does not occur.

Owner:YANCHENG INST OF IND TECH

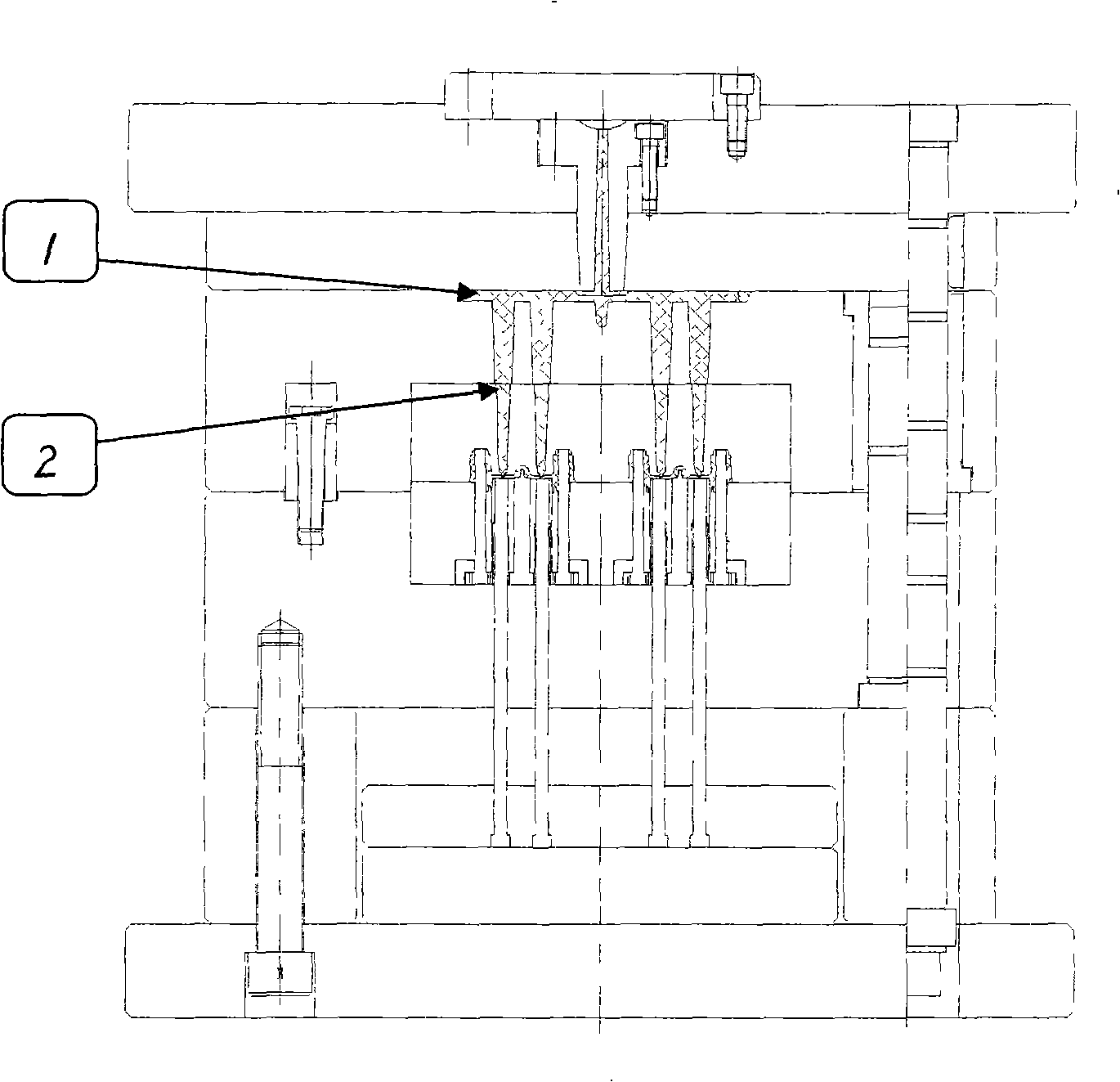

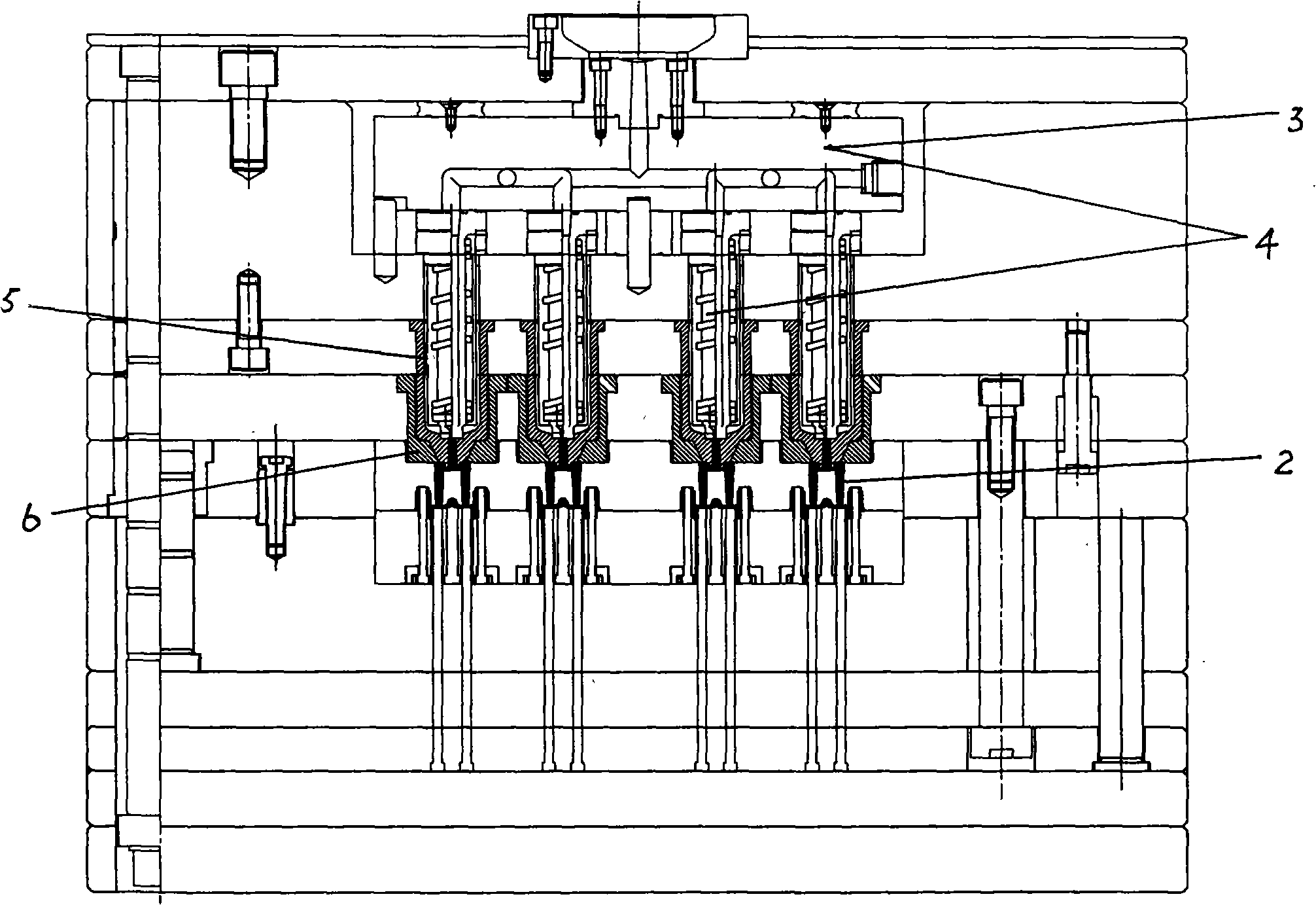

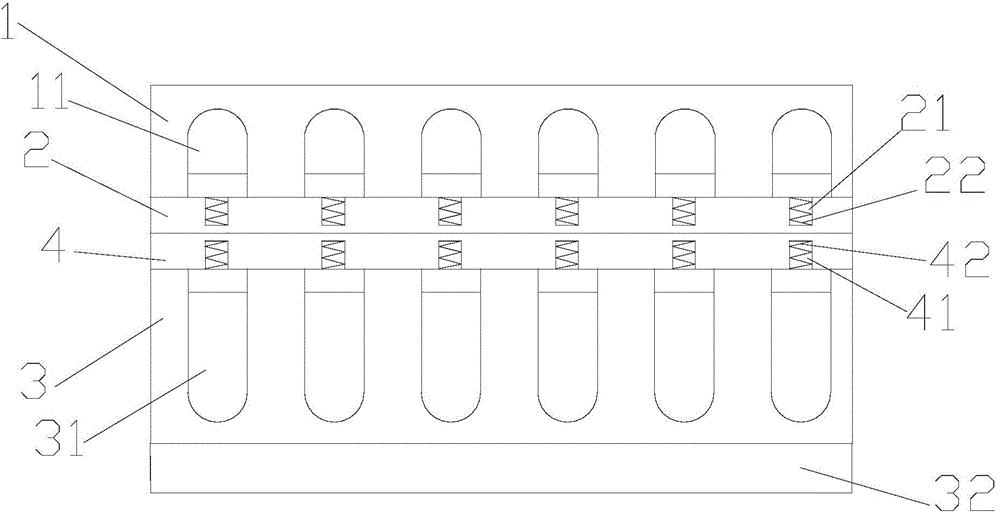

Multifunctional empty capsule manufacturing mould

The invention discloses a multifunctional empty capsule manufacturing mould. The multifunctional empty capsule manufacturing mould comprises an upper cover plate, an upper de-molding plate, a lower cover plate, a lower de-molding plate, a capsule cap mould core and a capsule body mould core, wherein the upper cover plate is positioned on the top of the mould; the upper de-molding plate is positioned under the upper cover plate, and the upper de-molding plate and the upper cover plate are mounted in a movable fit mode; the lower cover plate is positioned on the bottom of the mould; a base is further arranged on the bottom of the lower cover plate; a reinforcing rib is further arranged in the base; the lower de-molding plate is positioned above the upper cover plate, and the lower de-molding plate and the lower cover plate are mounted in the movable fit mode; the capsule cap mould core and the upper de-molding board are mounted in a threaded mode; the capsule body mould core and the lower cover plate are mounted in the threaded mode; and the cross section diameter of the capsule cap mould core is equal to that of the capsule body mould core. The multifunctional empty capsule manufacturing mould is good in heat dispersion, saves the production cost, has exchangeability, and ensures the quality and the safety of the capsules.

Owner:SHAOXING HAIBANG PHARMA

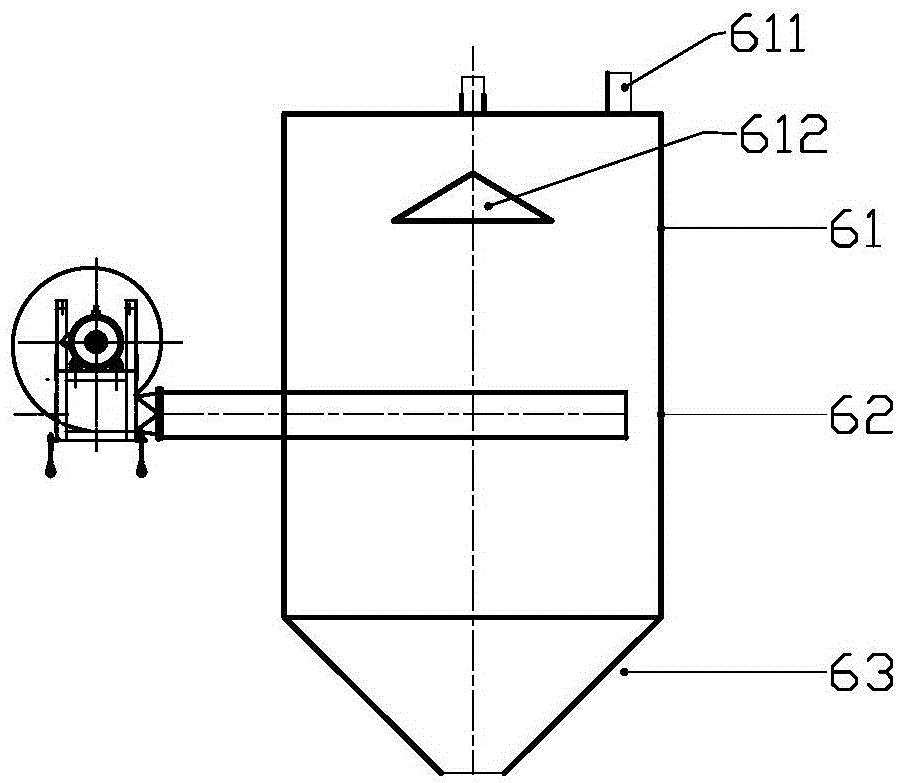

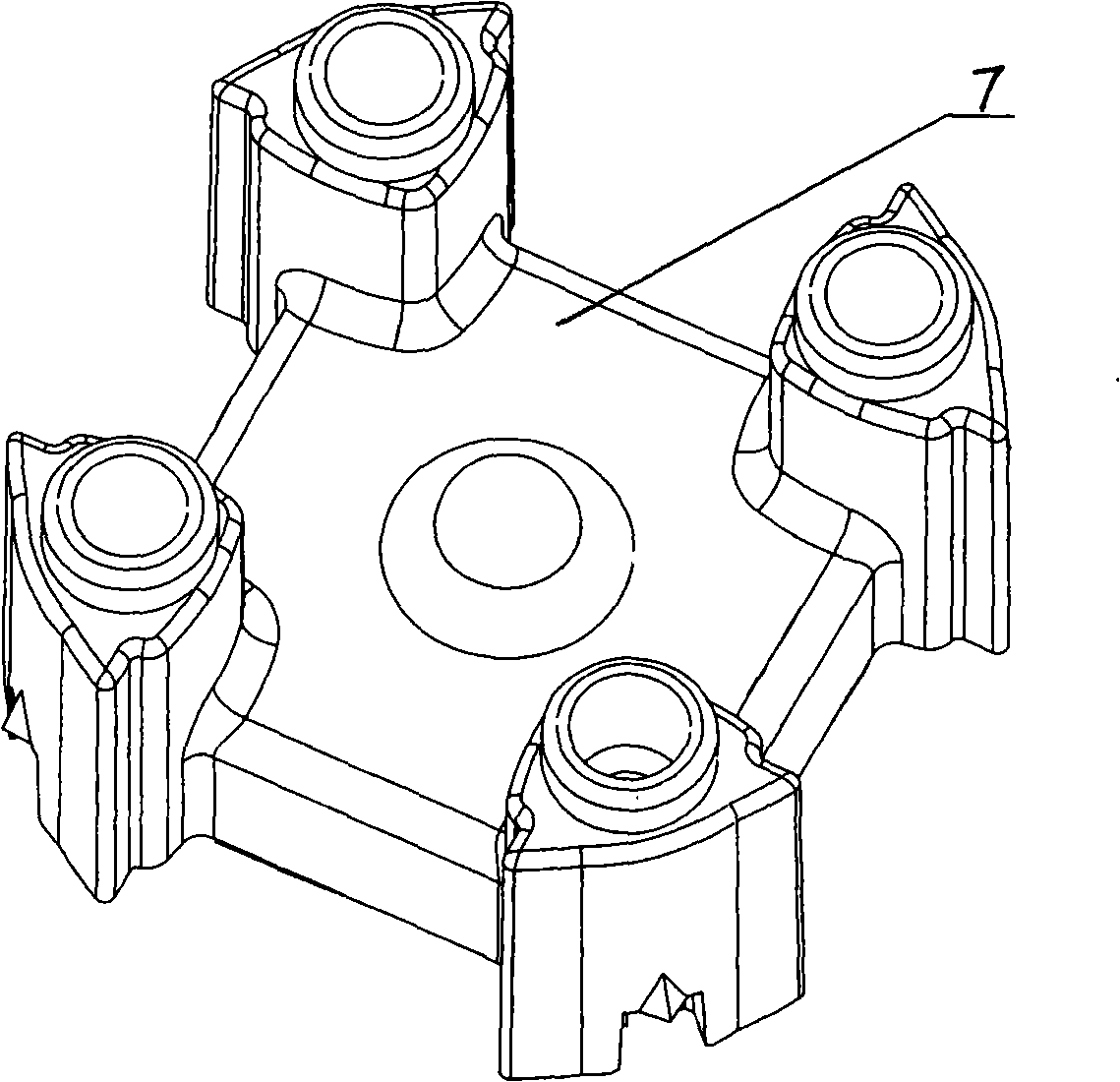

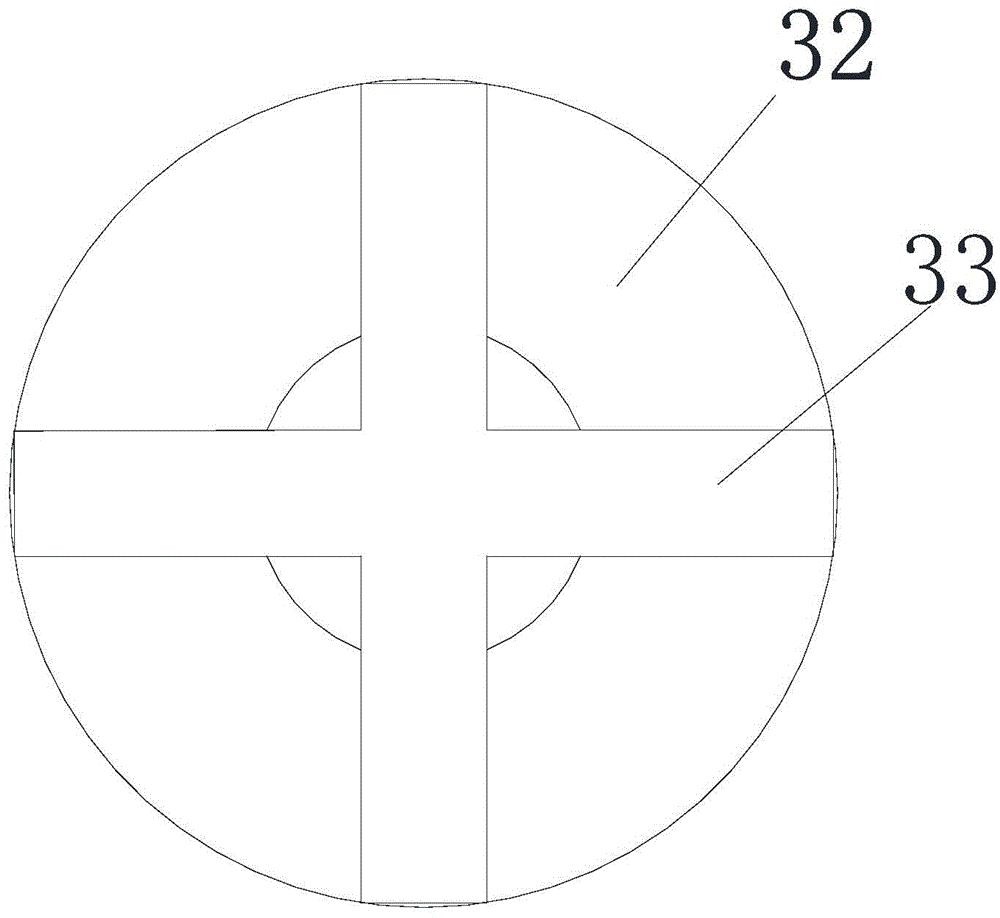

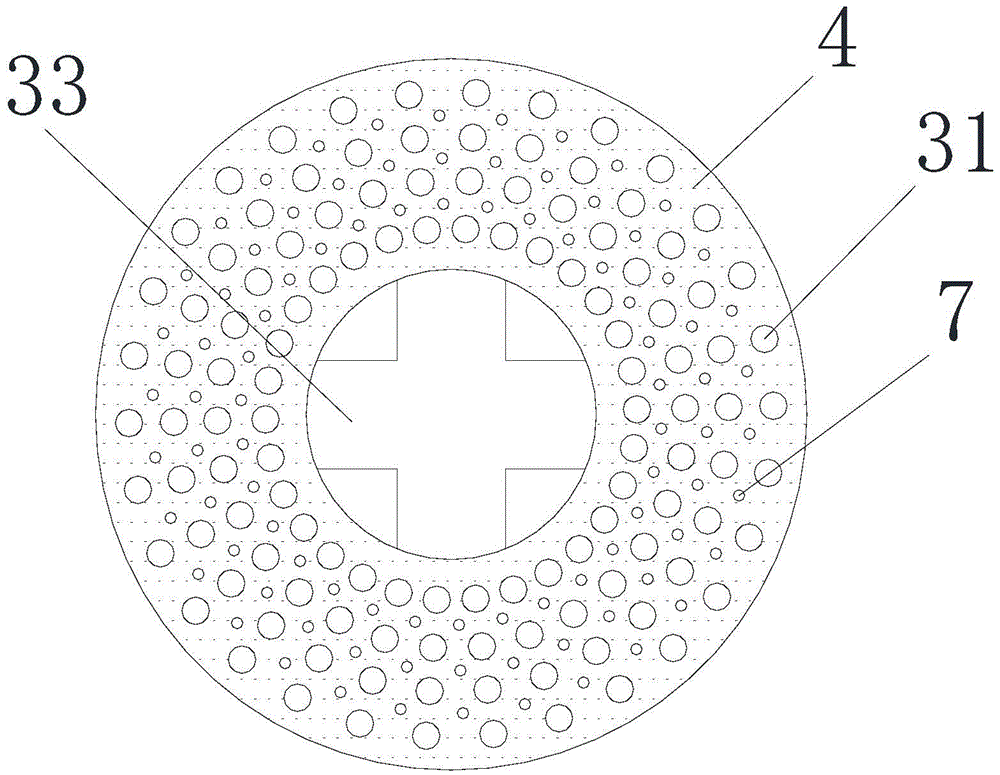

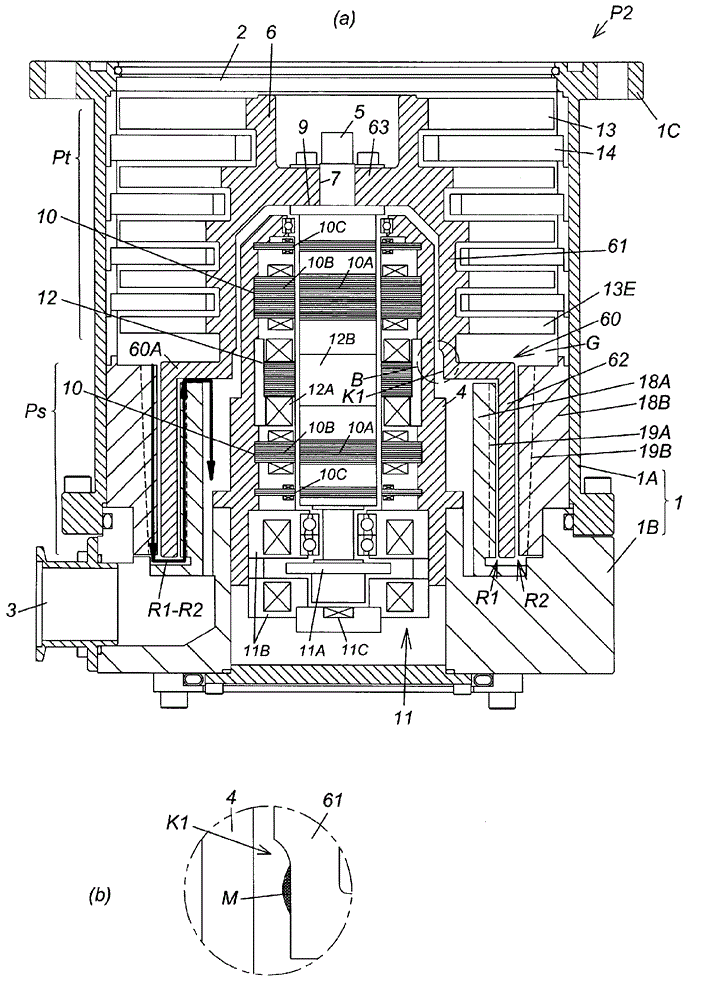

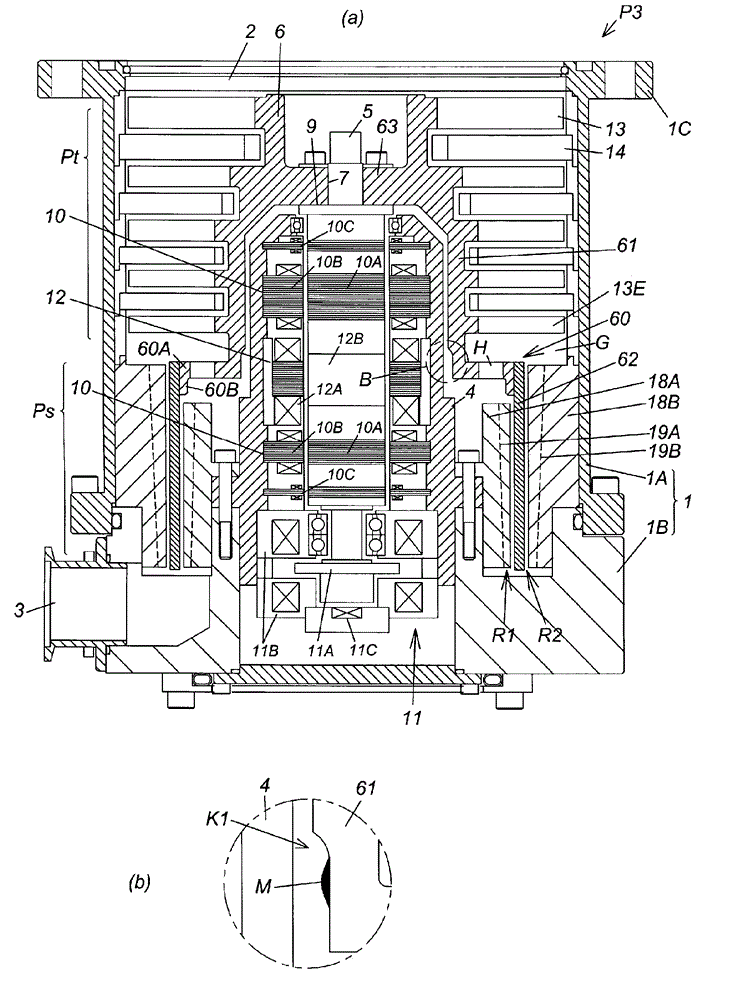

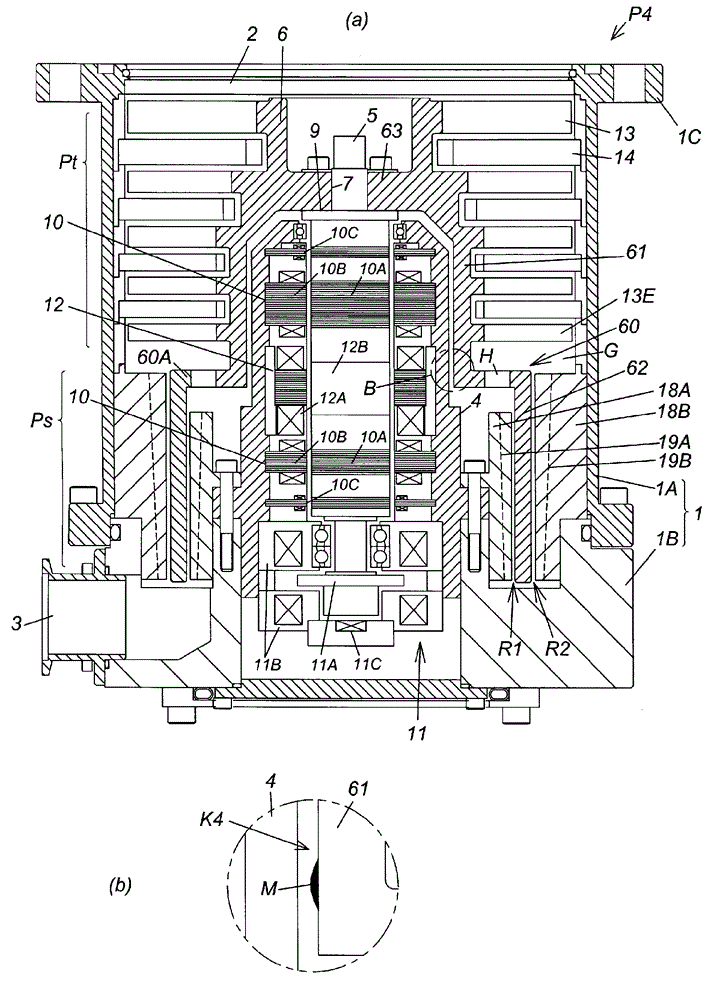

Rotor, and vacuum pump equipped with rotor

ActiveCN104541063AImprove the exhaust effectPrevent bad situationPump componentsEngine fuctionsEngineeringVacuum pump

[Problem] To provide a rotor that improves the evacuation capabilities of a vacuum pump, and that prevents shedding of fragments from a balancing section, and a vacuum pump equipped with this rotor. To provide a rotor for a vacuum pump suited to improving the evacuation capabilities of the vacuum pump and the operability of the balancing section, and that prevents shedding of fragments from the balancing section, or, in the unlikely event that shedding has occurred, affords rapid expulsion and rapid discovery thereof. [Solution] The rotor (6) of a vacuum pump (P1) is provided with first and second cylinders (61, 62) and a linking part (60) linking both of the cylinders (61, 62) together. The first cylinder (61) is provided on the outside peripheral surface with a plurality of rotating blades (13), these rotating blades (13) being arranged in alternating fashion to a plurality of stationary blades along the axial center of the vacuum pump to constitute a bladed evacuation section (Pt). A thread groove evacuation channel (R1) is formed on at least the inside peripheral side of the second cylinder (62), thereby constituting a thread groove evacuation section (Ps). In the rotor (6), a balancing section (K1) for the rotor (6) is furnished on the inside peripheral surface of the first cylinder (61) of the linking part (60), and this balancing section (K1) is furnished with a mass addition means (M).

Owner:EDWARDS JAPAN

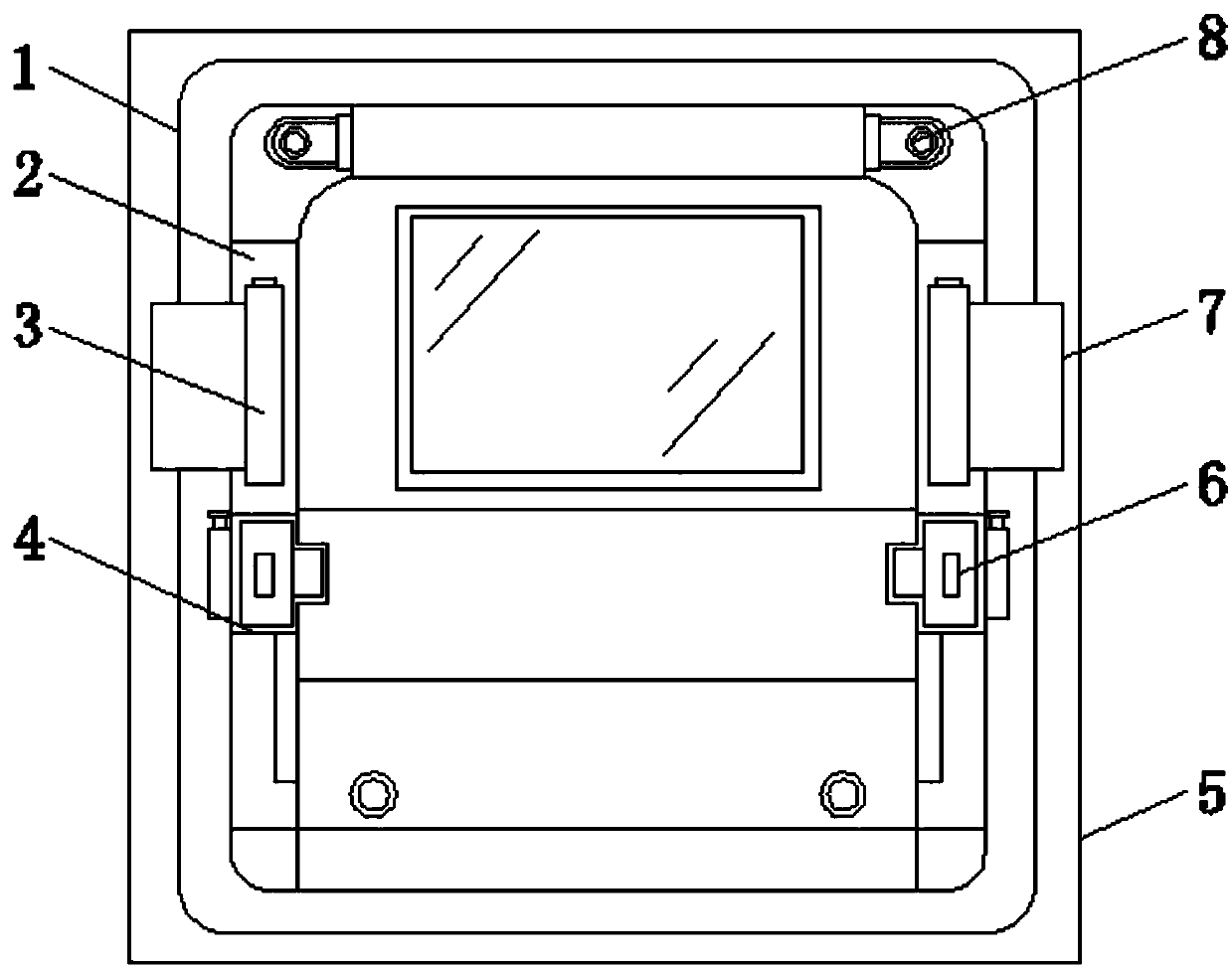

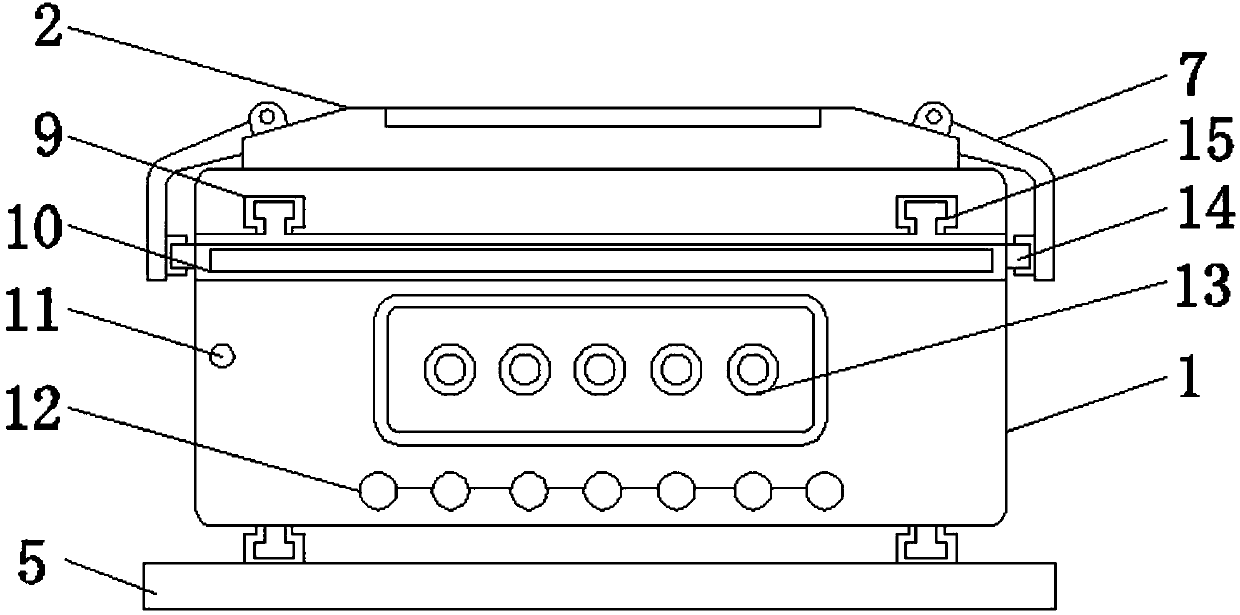

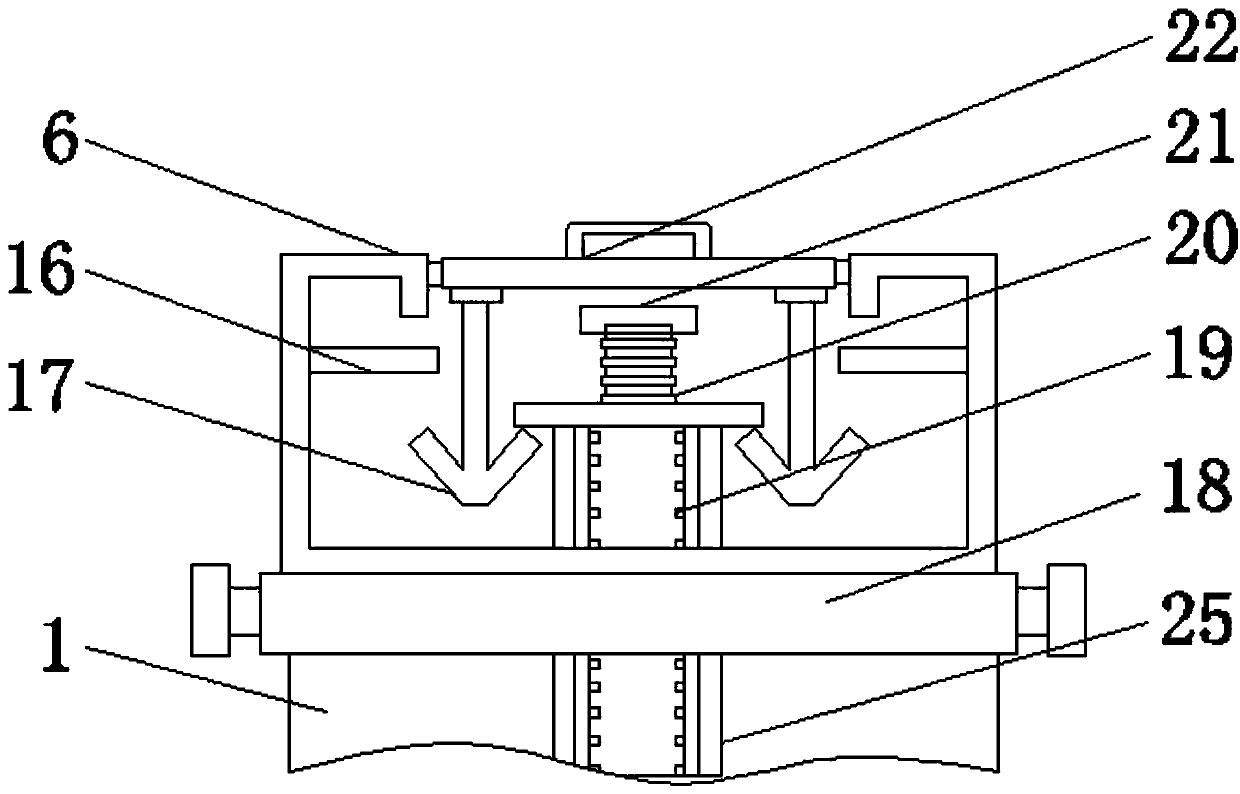

Electric energy meter modular assembly structure

InactiveCN107607756AEasy to assembleThe assembled structure is conveniently installed byTime integral measurementElectricityModularity

The invention relates to an electric energy meter modular assembly structure. The modular assembly structure comprises an electric energy meter box, an electric energy meter cover, an electric energymeter base and locks; second sliding grooves are formed in both ends of the top of the electric energy meter base, the electric energy meter box is installed on the upper sides of the second sliding grooves through second sliding blocks, first sliding blocks are installed at both ends of the top of the electric energy meter box, and the locks are hinged to the portions, on the outer sides of the first sliding blocks, of the top end of the electric energy meter box through second hinging shafts. According to the modular assembly structure, by installing the locks, stop blocks, elastic bodies, press lock blocks and pan head screws and forming blind holes in the electric energy meter cover, the pan head screws are installed in the blind holes to lock the electric energy meter cover, and thenthe press lock blocks are inserted in the locks; by hiding the pan head screws in plastic packages, terminal electricity customers are effectively prevented from operating internal hardware or a circuit board, and the secrecy performance is good.

Owner:胡小爱

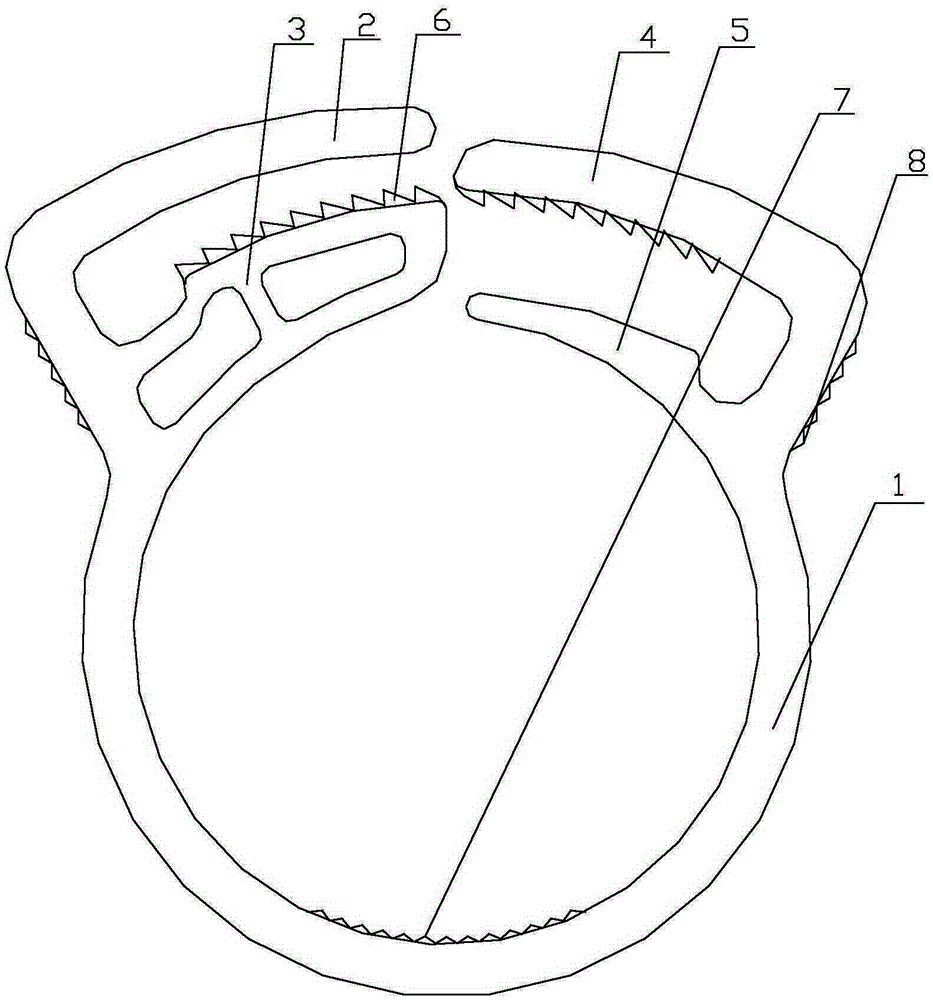

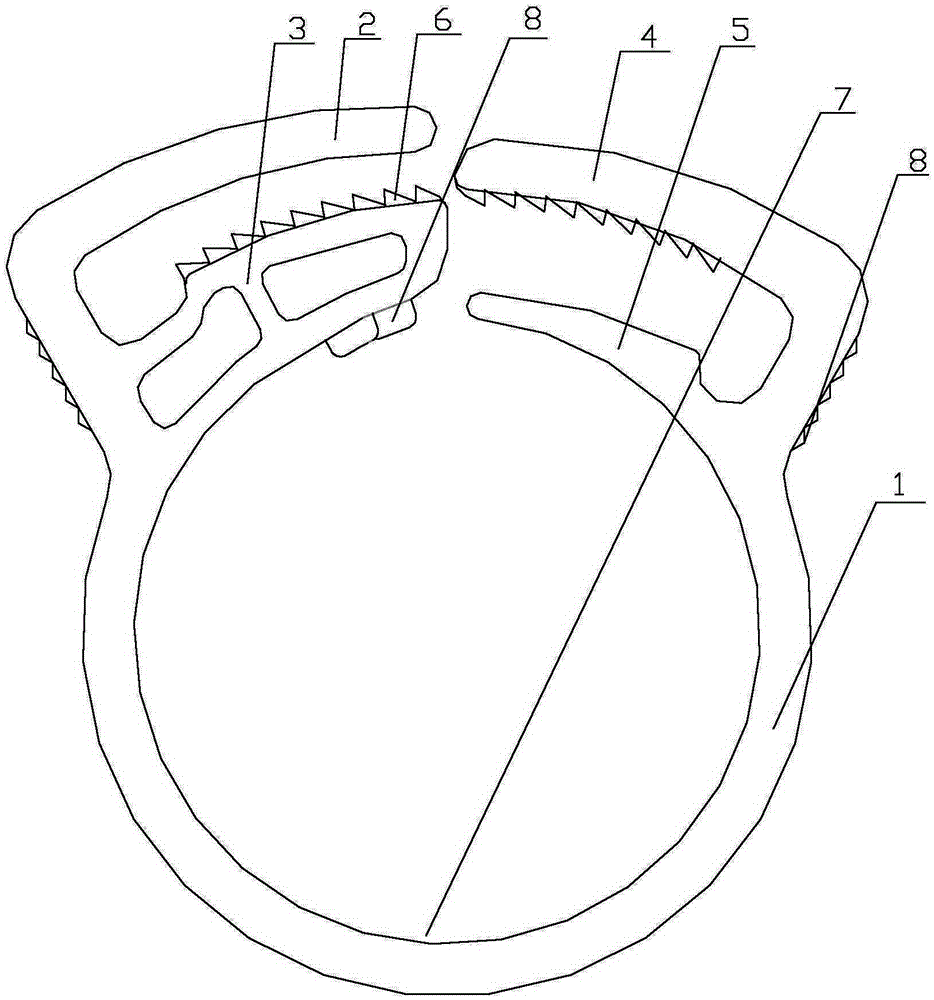

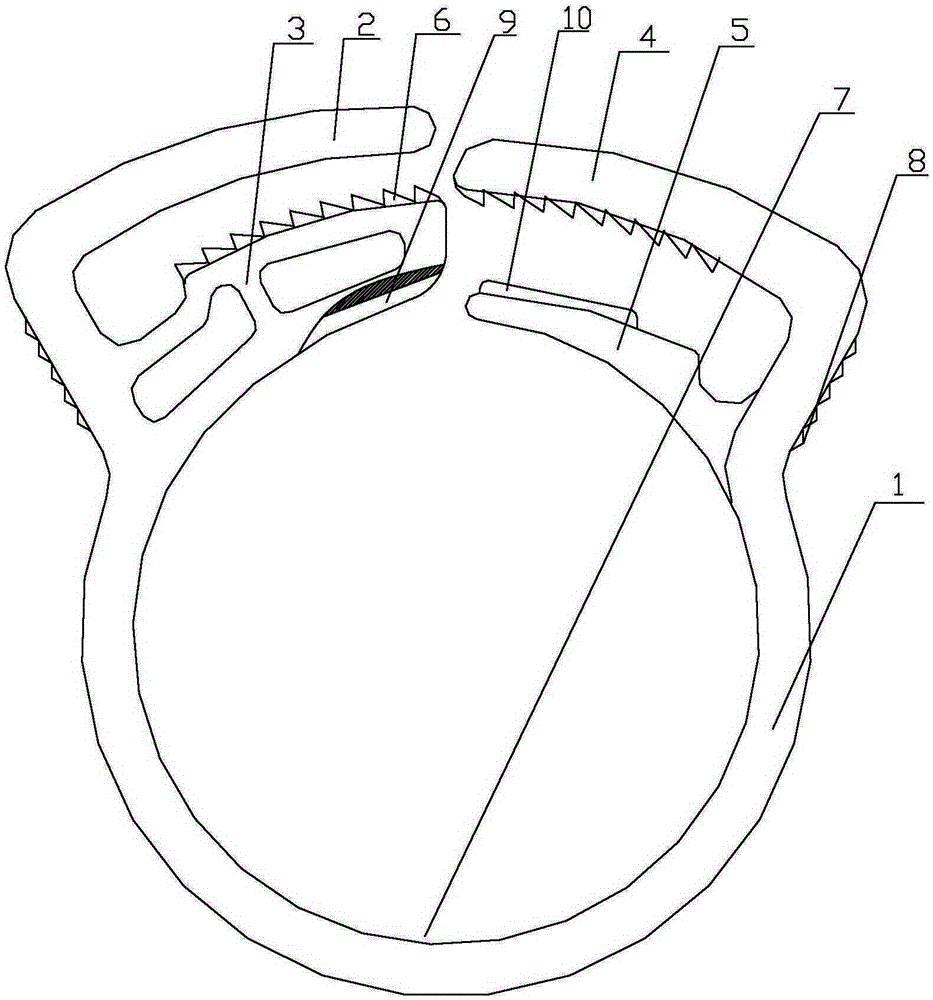

Annular locking mechanism used for wire harnesses

The invention discloses an annular locking mechanism used for wire harnesses and relates to a fixing device. A body of the annular locking mechanism is a semi-closed circular ring. An upper clamping plate and a lower latch plate are arranged at one end of the circular ring. An upper latch plate and a lower clamping plate are arranged at the other end of the circular ring. Latches which are opposite in tooth form are arranged in the upper latch plate and the lower latch plate respectively. The upper latch plate is arranged between the upper clamping plate and the lower latch plate. The lower latch plate is arranged between the upper latch plate and the lower clamping plate. The annular locking mechanism has the beneficial effects that the design is novel, the structure is simple, and a traditional plastic ribbon is improved to be in an annular shape; a normal locking function of the annular locking mechanism is guaranteed, and meanwhile a ring receding effect is achieved; material waste is avoided, using is convenient and fast, the structure is stable and firm, the practicability is high, and application and popularization are facilitated.

Owner:ANHUI ANLAN MOLD

Ball forming machine

ActiveCN109259288AAchieve extrusionAchieve kneadingFood coatingFood shapingEngineeringFood processing

The invention relates to the technical field of food processing and discloses a ball forming machine, comprising a barrel and a motor. The motor is connected with a spindle; the spindle is rotationally connected with a blowing box; the spindle is coaxially and fixedly connected with a turnplate; the turnplate is provided with arc protrusions; a driving disc is fixedly connected to the upper end ofthe spindle and is fixedly connected with a rotating bar; the rotating bar is hinged to a connection bar; the connecting bar is hinged to a rubbing plate; a cylinder is fixedly connected inside the barrel; a piston is slidably connected inside the cylinder and is fixedly connected with a push bar; a storage cylinder is fixedly connected to the upper end of the barrel; a floating plate is slidablyconnected inside the storage cylinder; a squeezing bar is fixedly connected to the upper surface of the floating plate; a supporting bent bar is fixedly connected to the upper end of the barrel; a second elastic balloon is fixedly connected to the support bent bar and is communicated with the cylinder; a spiral pipe is fixedly connected inside the barrel; the upper end of the spiral pipe is communicated with a collection bucket; the lower end of the barrel is provided with a discharge port. The ball forming machine has high ball production efficiency.

Owner:象山锦绣升平食品有限公司

Adsorption type efficient waste gas purification device based on magnetic particles

InactiveCN111530235AAchieve sheddingBalanced utilizationDispersed particle separationPhysical chemistryWaste gas

The invention discloses an adsorption type efficient waste gas purification device based on magnetic particles, and belongs to the technical field of waste gas treatment. According to the adsorption type efficient waste gas purification device based on the magnetic particles, a plurality of high-strength adsorption balls are adsorbed through an electromagnet disc to form an adsorption layer; the adsorption layer can be rotated, and blockage caused by non-uniform adsorption degree of the adsorption layer in each direction is avoided; meanwhile, different magnetic adsorption areas are sequentially arranged on the electromagnet disc from inside to outside, the magnetic adsorption areas are sequentially powered off from outside to inside during use according to the time limit, falling of the high-strength adsorption ball from outside to inside is realized, furthermore, uniform utilization of the high-strength adsorption balls laid inside and outside is further fully achieved, and adsorption blockage is avoided. When the falling high-strength adsorption balls are desorbed, breakage of the adsorption materials at the outer ends of the magnet balls is completed in combination with certaintemperature and rotary collision shearing, and subsequent collection and utilization of the magnet balls and the adsorption materials are facilitated.

Owner:黄龙标

Inoculating needle used for sterile operation

InactiveCN103952299AAchieve sheddingEasy to useBiological material testing proceduresCulture mediumsMaterials science

The invention relates to an inoculating needle used for a sterile operation. The inoculating needle used for the sterile operation comprises a handle, a locking end cover, a nickel alloy spring ring, a connecting rod, a sliding block, a pretight spring and a needle body, wherein a round hole and a cross-shaped seam are formed in a fixed part of the handle, one locking end cover is fastened on the fixed part, one nickel alloy spring ring is sheathed on the upper part of the needle body, one connecting rod is connected with the outer side of the nickel alloy spring ring in a welding way, the connecting rod is penetratively arranged in a groove of the handle along the axial direction, a groove in a mounting part is a pretight spring mounting cavity, an annular secondary auxiliary barrel is sheathed outside a corresponding mounting part, a linear sliding chute and a sliding block are arranged in the axial direction of a secondary barrel, the sliding block is connected with a stirring rod fixed on the connecting rod into a whole by virtue of a fastening structure, and the pre-tight spring can cause that the connecting rod tends to move in the direction far away from one end of the needle body. The sliding block is pushed by virtue of a thumb, so that the nickel alloy spring ring quickly stretches out, a fungus block is fallen off, inoculation time is shortened, long-time contact between a culture medium and the outside air is avoided, and pollution probability is reduced.

Owner:MAIZE RES INST SHANDONG ACAD OF AGRI SCI

Quick-opening device for filter board of pressure filter

The invention discloses a quick-opening device for a filter board of a pressure filter. A roller set is arranged on a filter board set. Unit filter boards in the filter board set are respectively connects to unit rollers in the roller set. A moving mechanism used for moving the unit rollers in the movable roller set along a main beam is arranged on the main beam. The moving mechanism comprises atleast two oil cylinders used for unloading, at least two electromagnets, and a controller used for controlling the power-on and power-off of the electromagnets. The electromagnets are arranged on theoil cylinders, and are electrically connected with the controller. The electromagnets are slidably coupled with the main beam. Unit cylinders of the at least two cylinders are arranged on a horizontal direction of the main beam. The quick-opening device provided by the invention is advantaged in that: when the number of the filter boards is large, sectioned blanking is adopted. That is to say, the stroke of a compaction cylinder is maintained, and the at least two oil cylinders used for unloading are arranged on the main beam.

Owner:浙江雅顿环境科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com