Method for recycling rear-earth elements form abandoned fluorescent lamps

A rare earth element and fluorescent lamp technology, applied in the direction of improving process efficiency, can solve the problems of cumbersome steps, no industrialization, secondary environmental pollution, etc., and achieve the effect of simple and convenient reaction, easy popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

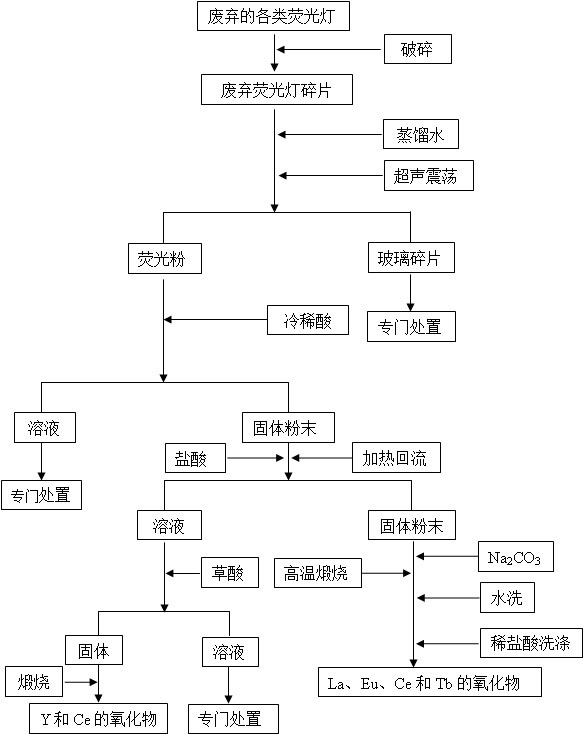

Image

Examples

Embodiment 1

[0019] (1) Use a crusher to break the waste fluorescent lamp into pieces of about 2 mm, then add a certain amount of distilled water, the liquid surface is not over the glass pieces, use a plug-in ultrasonic oscillator to realize the stripping of the fluorescent powder, and wet through an 80-mesh sieve , Separation and collection of phosphor powder in waste fluorescent lamps.

[0020] (2) Put the fluorescent powder into a flask, add 0.1M hydrochloric acid, soak at room temperature for 2 hours, filter and separate the precipitate, add 1M hydrochloric acid, reflux at 80°C for 2 hours, filter and separate to obtain rare earth elements solution and some insoluble phosphate and other rare earth phosphors.

[0021] (3) Add saturated oxalic acid solution to the rare earth element-containing solution to obtain a rare earth element precipitate, filter and separate, and calcinate at 400 ° C for one hour to obtain a high-quality rare earth oxide phosphor.

[0022] (4) Mix the solid samp...

Embodiment 2

[0024] Other contents and operations are the same as in Example 1, except that in step (2), the temperature is 90°C for reflux reaction for 1 hour, and the solution containing rare earth elements and some insoluble rare earth phosphors can also be separated; In step (3), the calcination temperature is 300°C for two hours, and high-quality rare earth oxide phosphors can also be obtained; in step (4), the calcination temperature is 1000°C, and calcination is for 2 hours, and high quality rare earth oxide phosphors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com