Annular locking mechanism used for wire harnesses

A locking mechanism and ring-shaped technology, applied in the direction of flexible and slender elements, packaging, transportation and packaging, etc., can solve the problems of lack of comprehensive utilization, unreasonable operation, high production cost, etc., and achieve strong practicability and structure The effect of stability, firmness and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below with reference to specific embodiments and drawings.

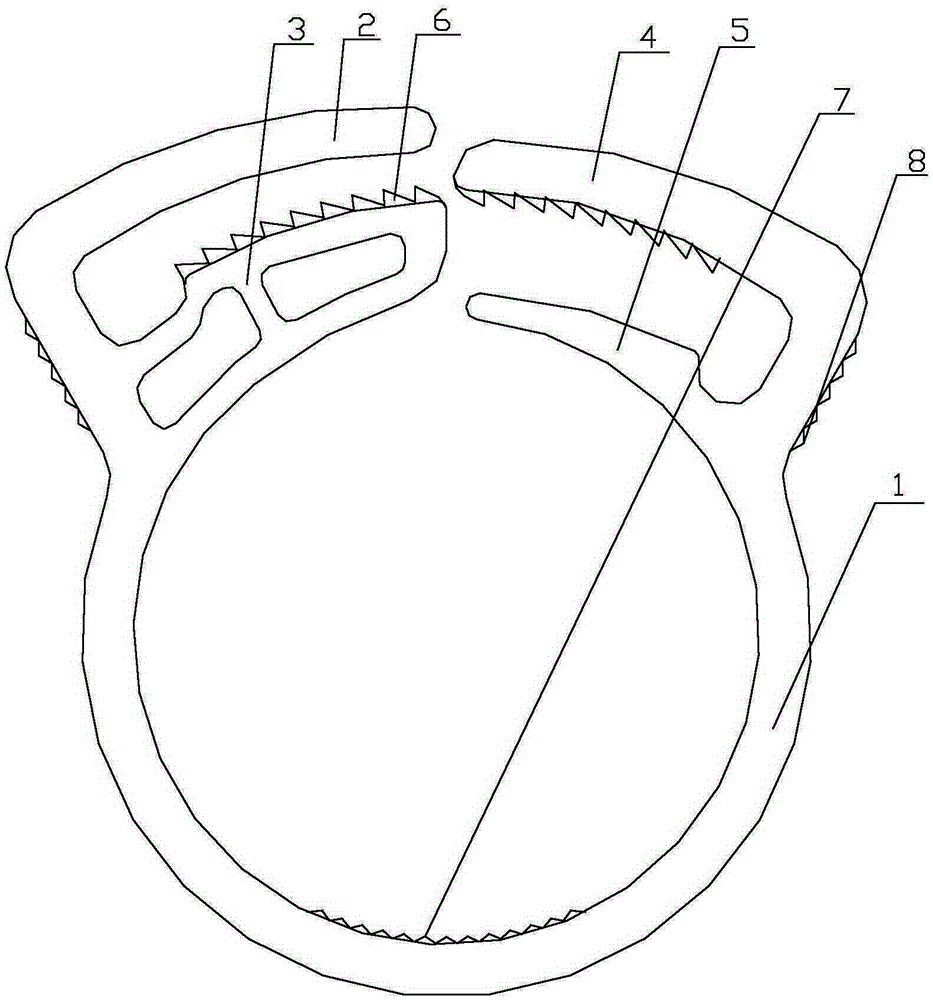

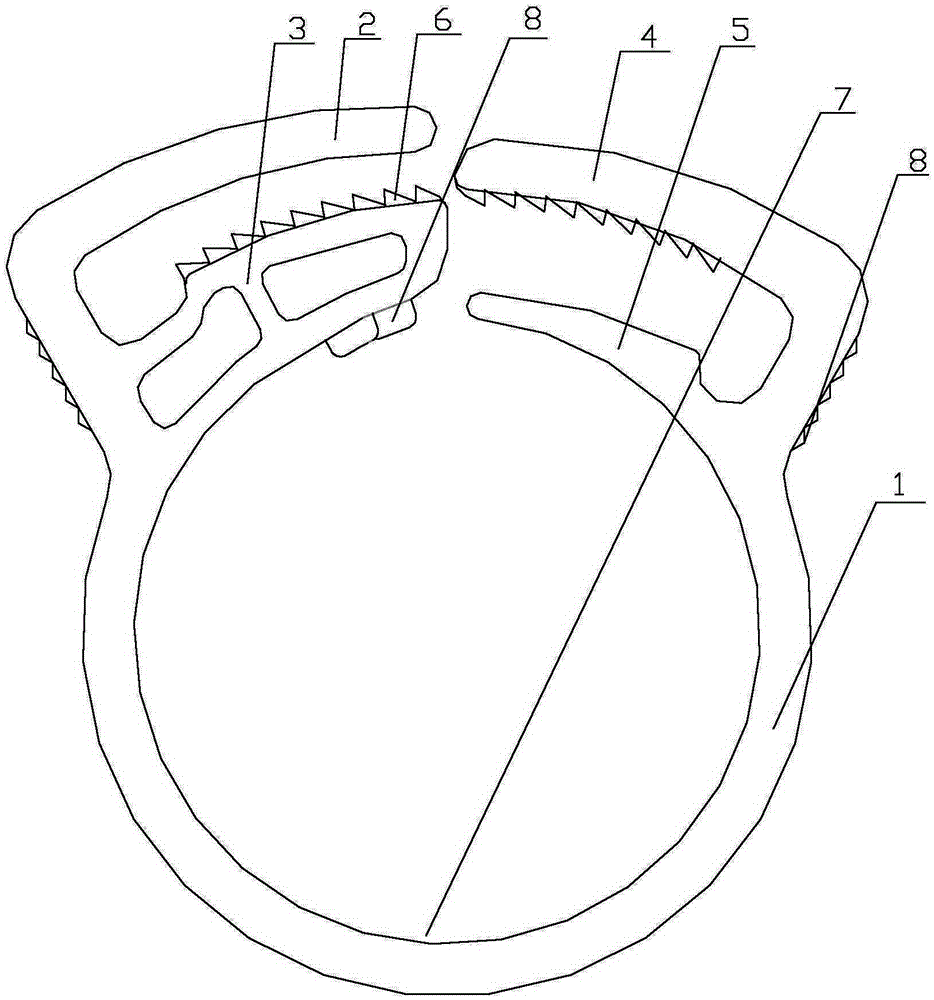

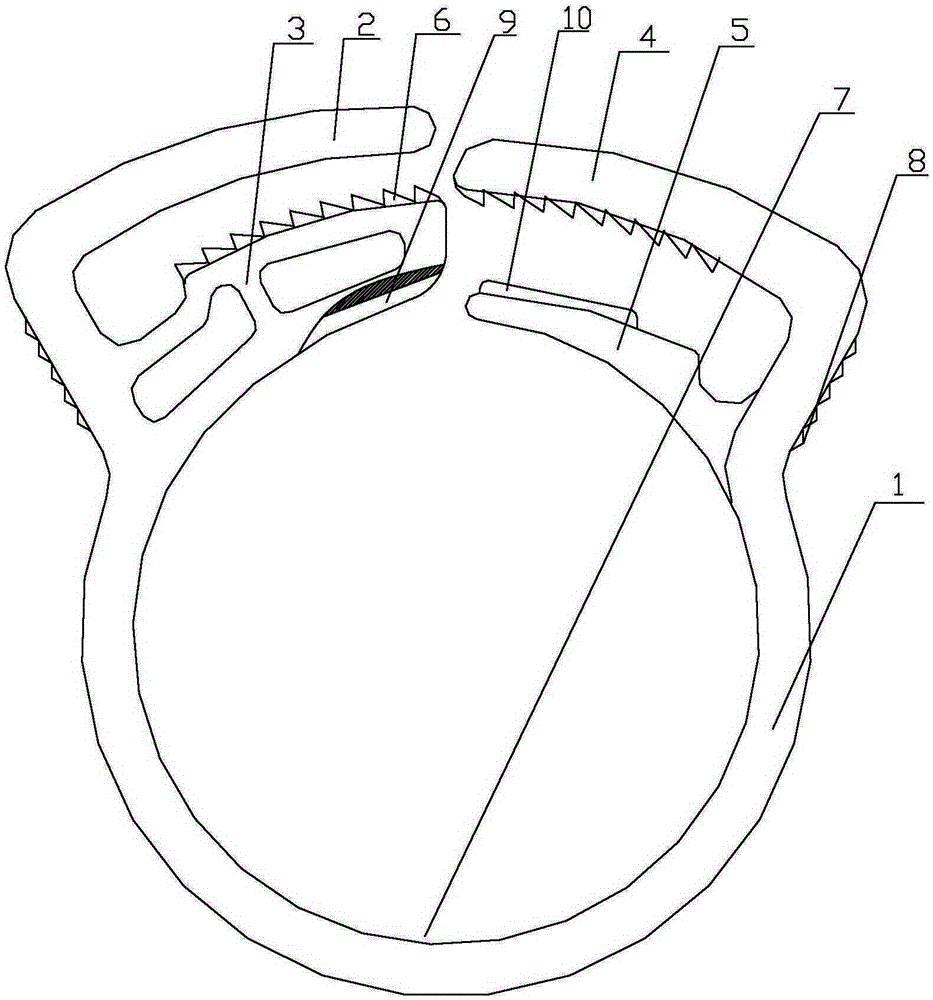

[0017] Such as figure 1 As shown, an annular locking mechanism for a wire harness, the main body is a half-closed ring 1, one end of the ring 1 is provided with an upper splint 2 and a lower clamping plate 3, and the other end of the ring 1 is provided with an upper The clamping gear plate 4 and the lower clamping plate 5, the upper clamping gear plate 4 and the lower clamping gear plate 3 are provided with clamping teeth 6 with opposite tooth shapes, and the upper clamping gear plate 3 is arranged between the upper clamping plate 2 and the lower clamping gear plate 3. The lower clamping gear plate 3 is set between the upper clamping gear plate 4 and the lower clamping plate 5. After this setting, when the wire harness needs to be locked, first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com