Inoculating needle used for sterile operation

A technique for aseptic operation and inoculation needles, which is applied in the field of inoculation needles to achieve the effect of reducing the probability of contamination, being convenient to use, and avoiding prolonged contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

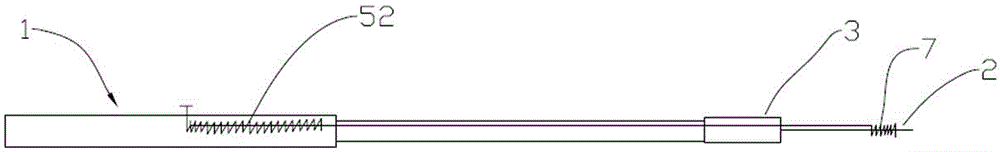

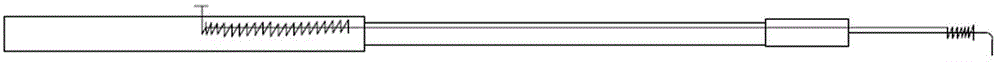

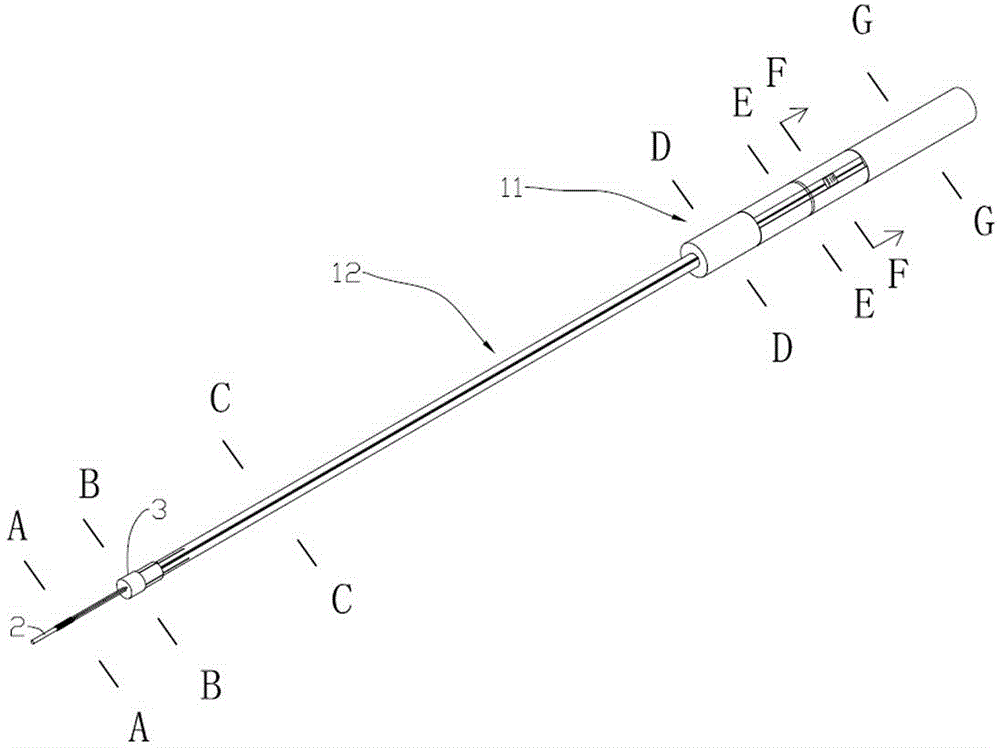

[0040] Embodiment one, such as Figure 1 to Figure 14 as shown,

[0041] An inoculation needle for aseptic operation, comprising a handle, a locking end cap, a nickel alloy spring coil, a connecting rod, a slider, a pretension spring, an auxiliary cylinder and a needle body.

[0042] The handle 1 is made of stainless steel, and includes two parts: a handle part 11 and a needle body fixing part 12. Hand-held part 11, as the name suggests, is a hand-held part, made of bakelite with good heat resistance, which is often used in pots and other occasions, needle body fixing part 12 is made of copper or stainless steel rods, in the needle body fixing part A round hole 13 for inserting the needle body 2 is provided at the end of the round hole, and a cross seam 14 is arranged on the rod around the round hole. Through the cooperation of a locking end cap 3, it shrinks and realizes the needle The body is fixed, and the locking form between the two is a buckle. An annular mounting gro...

Embodiment 2

[0051] Embodiment two, such as Figure 15 to Figure 16 As shown, the principle is basically the same as that of Embodiment 1, and its structure is described in detail below:

[0052] An inoculation needle for aseptic operation, comprising a handle, an elastic body, a nickel alloy spring coil, a connecting rod, a slider, a pre-tension spring and a needle body.

[0053] One of the differences from Embodiment 1 is that a circular hole 13' for inserting the needle body of the inoculation is provided at the fixed part, and a conical hole is provided at the fixed part of the circular hole, and a truncated cone is installed in the conical hole. Shaped elastic body 8 preferably adopts a rubber block, and the elastic body fixes the needle body in the round hole through extrusion deformation, and the depth is adjustable, so that the fast fixing of the needle body can be realized.

[0054] The second difference from Embodiment 1 is that the installation position of the connecting rod is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com