Multifunctional empty capsule manufacturing mould

A hollow capsule and multi-functional technology, which is applied in the field of pharmaceutical equipment and multi-functional hollow capsule making molds, can solve the problems of high heat absorption of solid mold cores, slow glue drying process, and prone to plum blossoms, etc., to save resources and heat dissipation Good effect and good resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

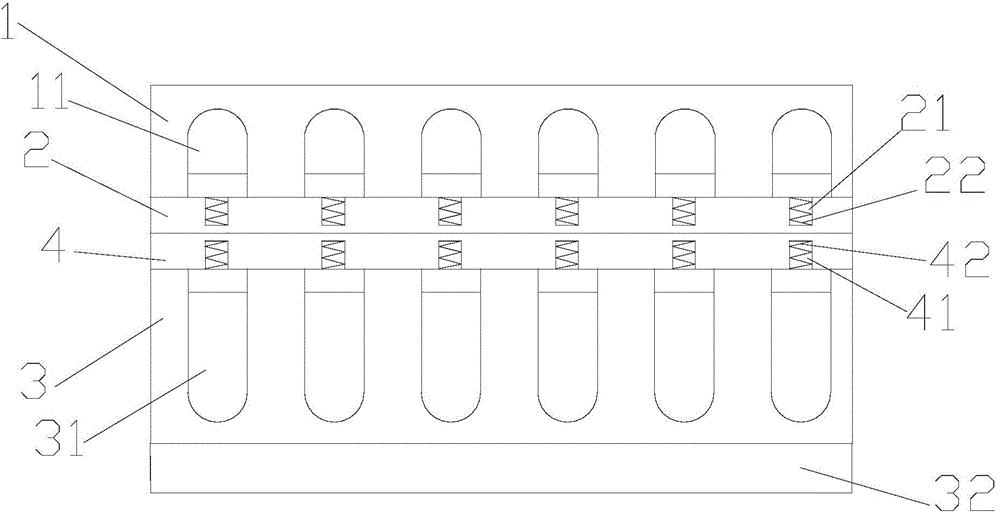

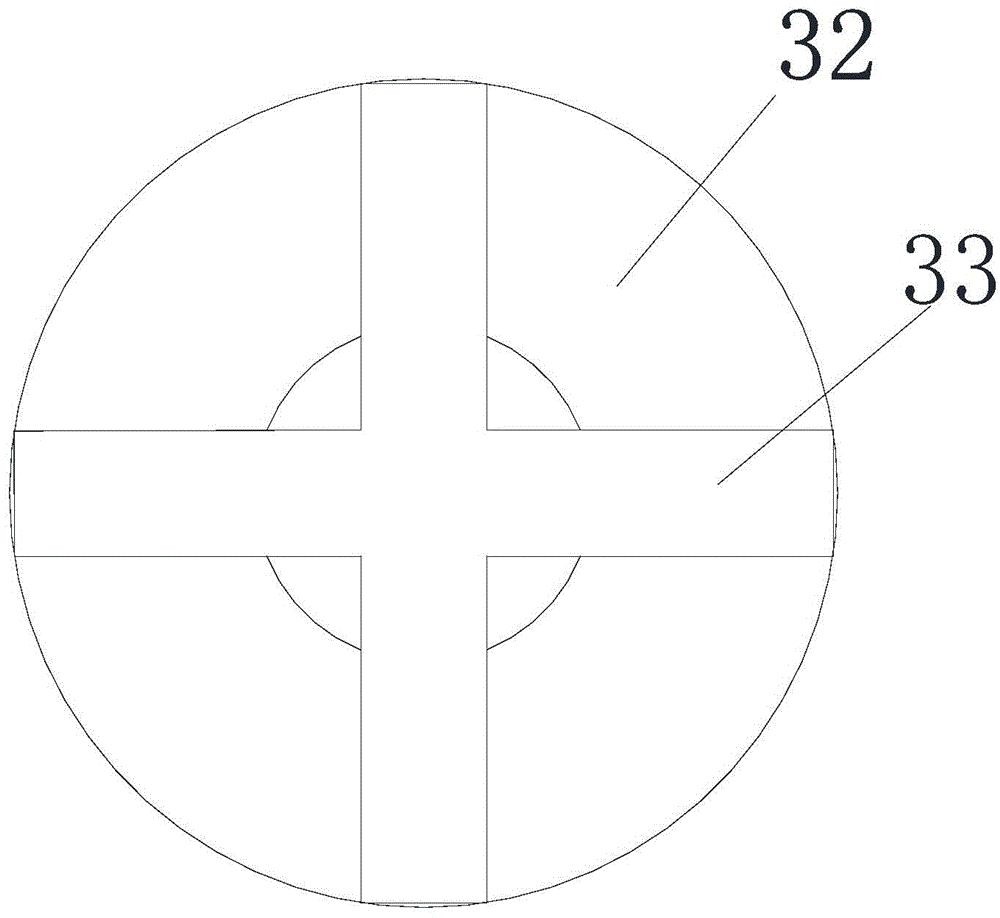

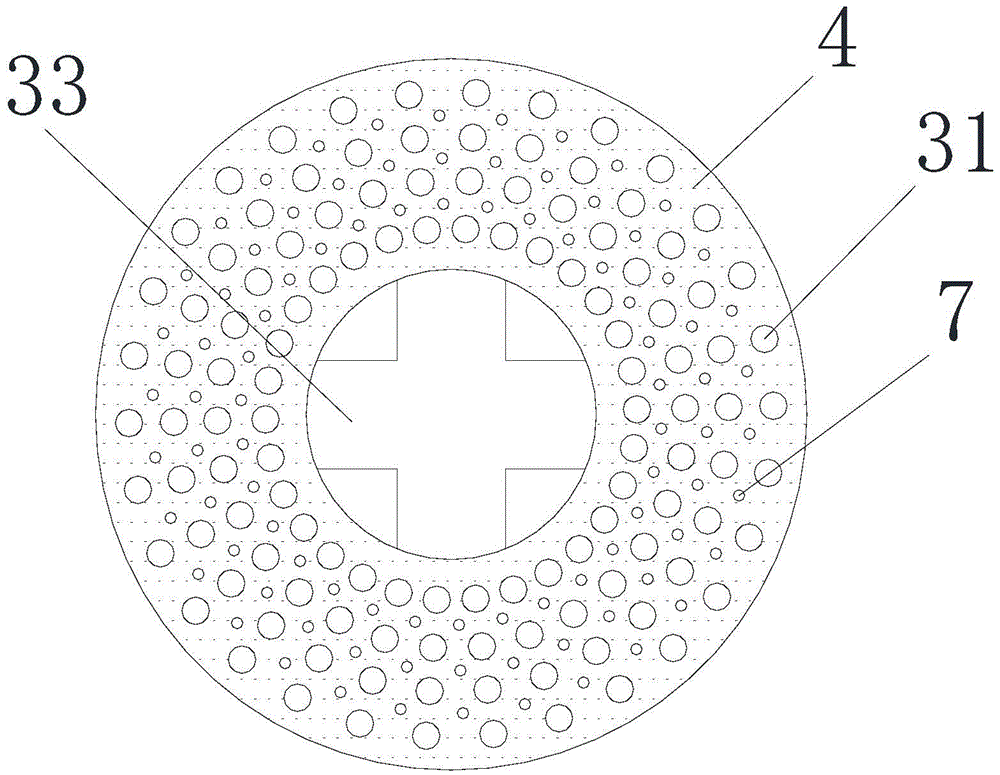

[0020] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , a multifunctional hollow capsule manufacturing mold of the present invention comprises an upper cover plate 1, an upper stripping plate 2, a lower cover plate 3, a lower stripping plate 4, a capsule cap mold core 5 and a capsule body mold core 6, and the upper cover plate 1 is located at On the top of the mould, the upper stripping plate 2 is located directly below the upper cover plate 1, and is movably fitted with the upper cover plate 1. The lower cover plate 3 is located at the bottom of the mould, and the bottom of the lower cover plate 3 is also provided with a base 32, the base 32 is also provided with reinforcing ribs 33, the lower stripping plate 4 is located above the lower cover plate 3 and is movably fitted with the lower cover plate 3, the capsule cap mold core 5 is threaded with the upper stripping plate 2, and the capsule body mold core 6 is connected with the upper strip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com