Ultrasonic cleaning equipment for power battery production

A technology for power batteries and cleaning equipment, which is applied to lighting and heating equipment, cleaning methods using liquids, cleaning methods, and utensils, and can solve the problems of batteries needing to wait for a period of time to dry freely, difficult to handle, and incomplete cleaning of batteries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

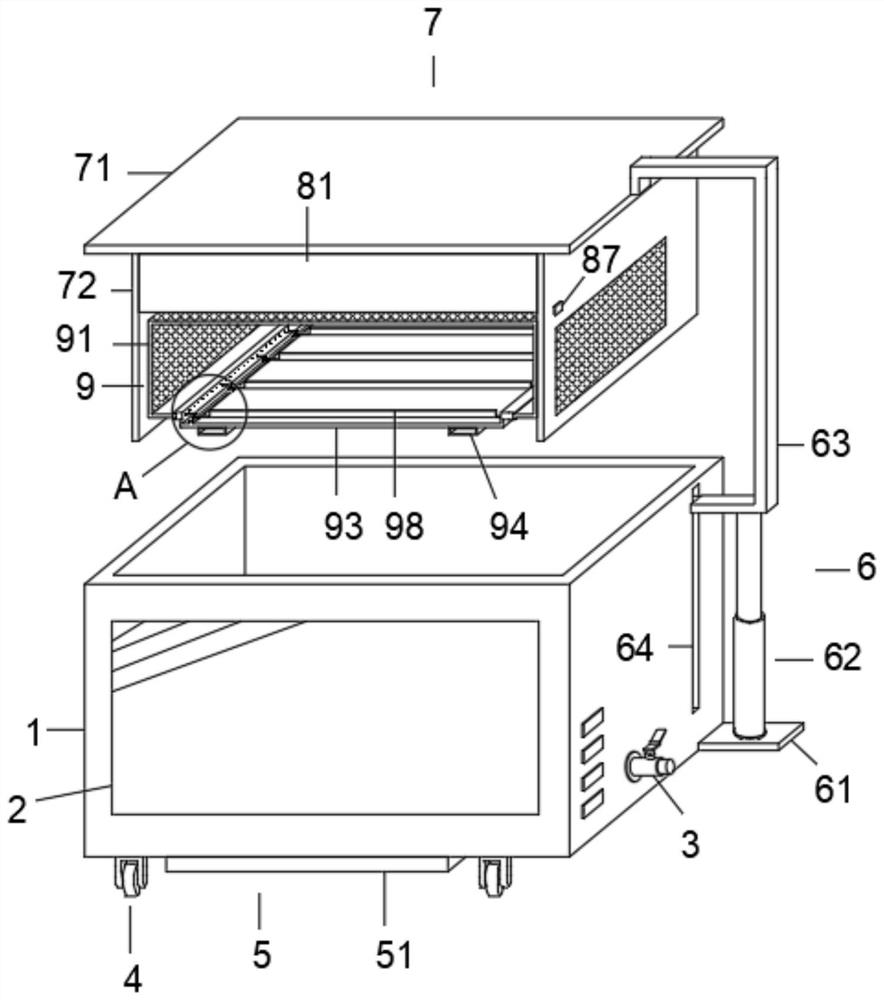

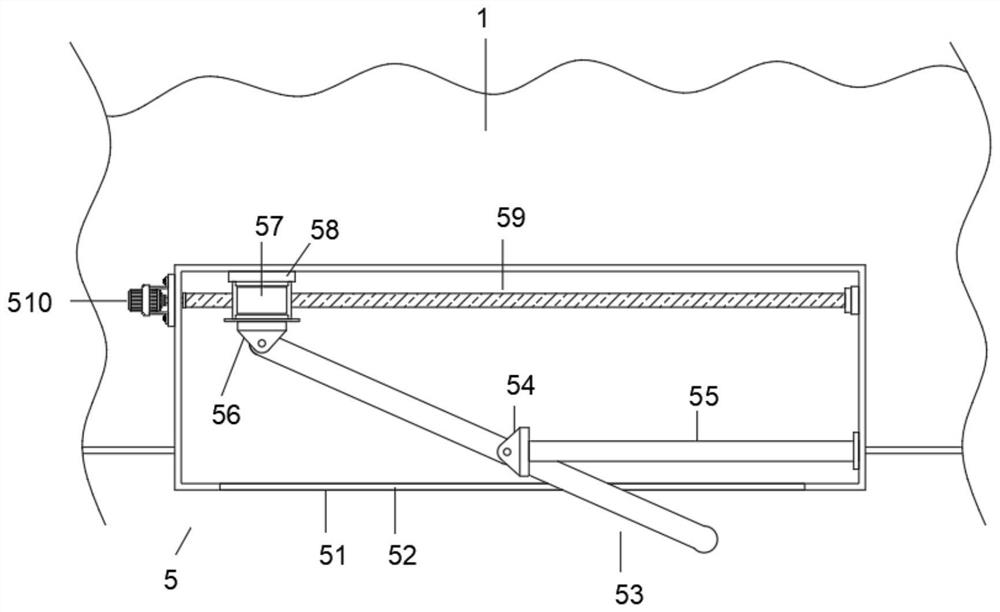

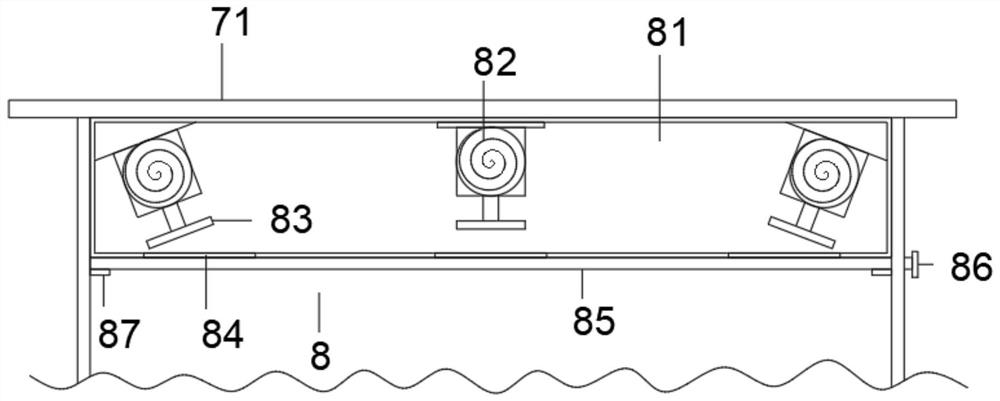

[0027] like Figure 1-4 As shown, this specific embodiment adopts the following technical solutions: an ultrasonic cleaning device for power battery production, including an ultrasonic cleaner body 1, the model of the ultrasonic cleaner body 1 is CJ-010B, and the ultrasonic cleaner body 1 is CJ-010B. The front of the washer body 1 is provided with an observation window 2, and the lower part of one side of the ultrasonic cleaner body 1 is fixedly connected with a sewage pipe 3, and the sewage pipe 3 is provided with a switching valve. The four corners of the bottom are fixedly connected with moving wheels 4, and a bottom fixing mechanism 5 is arranged on the body 1 of the ultrasonic cleaner between the moving wheels 4, and a loading and unloading mechanism 5 is arranged on the body 1 of the ultrasonic cleaner on one side of the sewage pipe 3. Mechanism 6, the top of the loading and unloading mechanism 6 is connected with a top sealing mechanism 7, the top sealing mechanism 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com