A horizontal cold water pump

A cold water pump, horizontal technology, applied in the direction of non-variable-capacity pumps, non-displacement pumps, pumps, etc., to prevent clogging, rapid cooling, and avoid volatile effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

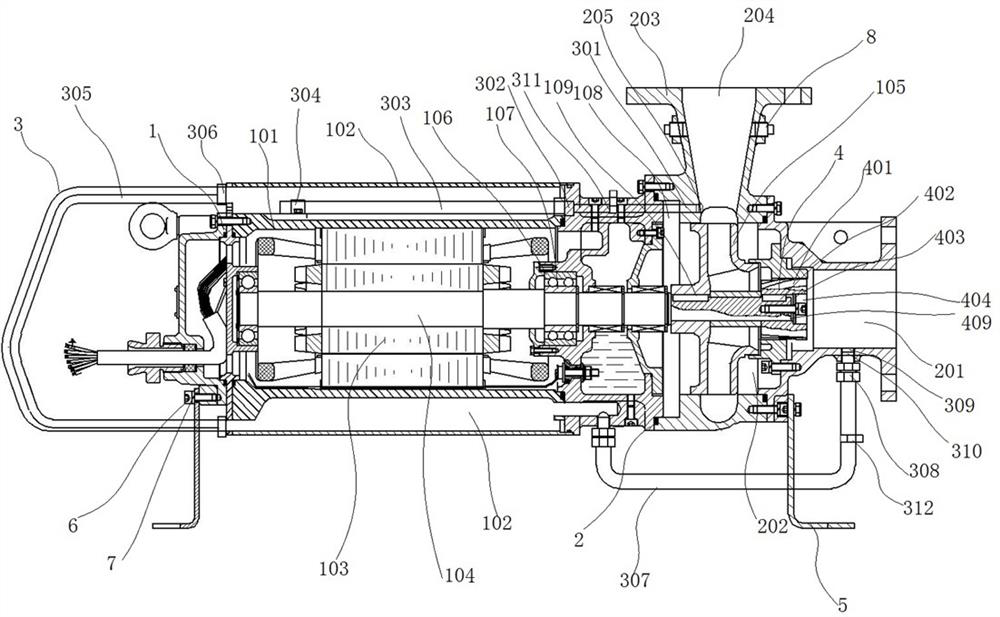

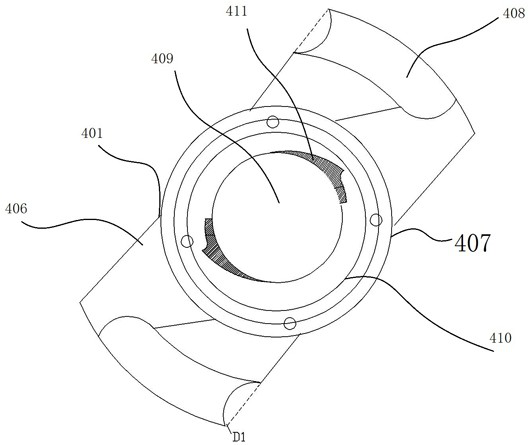

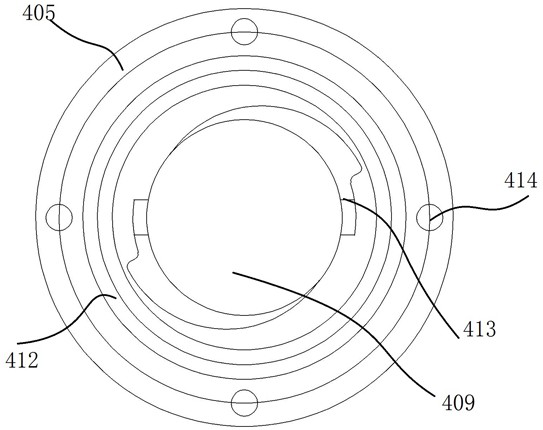

[0021] A horizontal cold water pump, comprising a motor assembly assembly 1, a volute assembly 2, a circulating cooling filter assembly 3 and a cutting assembly 4, the side end of the motor assembly assembly 1 is equipped with a circulating cooling filter assembly 3 and sealed and fixed thereto connected, a circulating cooling filter assembly 3 is installed between the motor assembly assembly 1 and the circulating cooling filter assembly 3 and a cooling cycle is formed through it, and a cutting assembly 4 is installed in the volute assembly 2, and the cutting assembly 4 Transmission connection with the motor assembly 1;

[0022] The motor assembly assembly 1 is provided with two chambers, including a motor sealing chamber 101 and a cooling sealing chamber 102. The upper and lower ends of the motor sealing chamber 101 are respectively provided with a coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com