Cooling system for a fuel cell

A cooling system, fuel cell technology, applied in fuel cells, fuel cell additives, circuits, etc., can solve problems such as reducing the efficiency of fuel cell systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] At the outset, like reference numerals have been assigned to like parts of the illustrated embodiment.

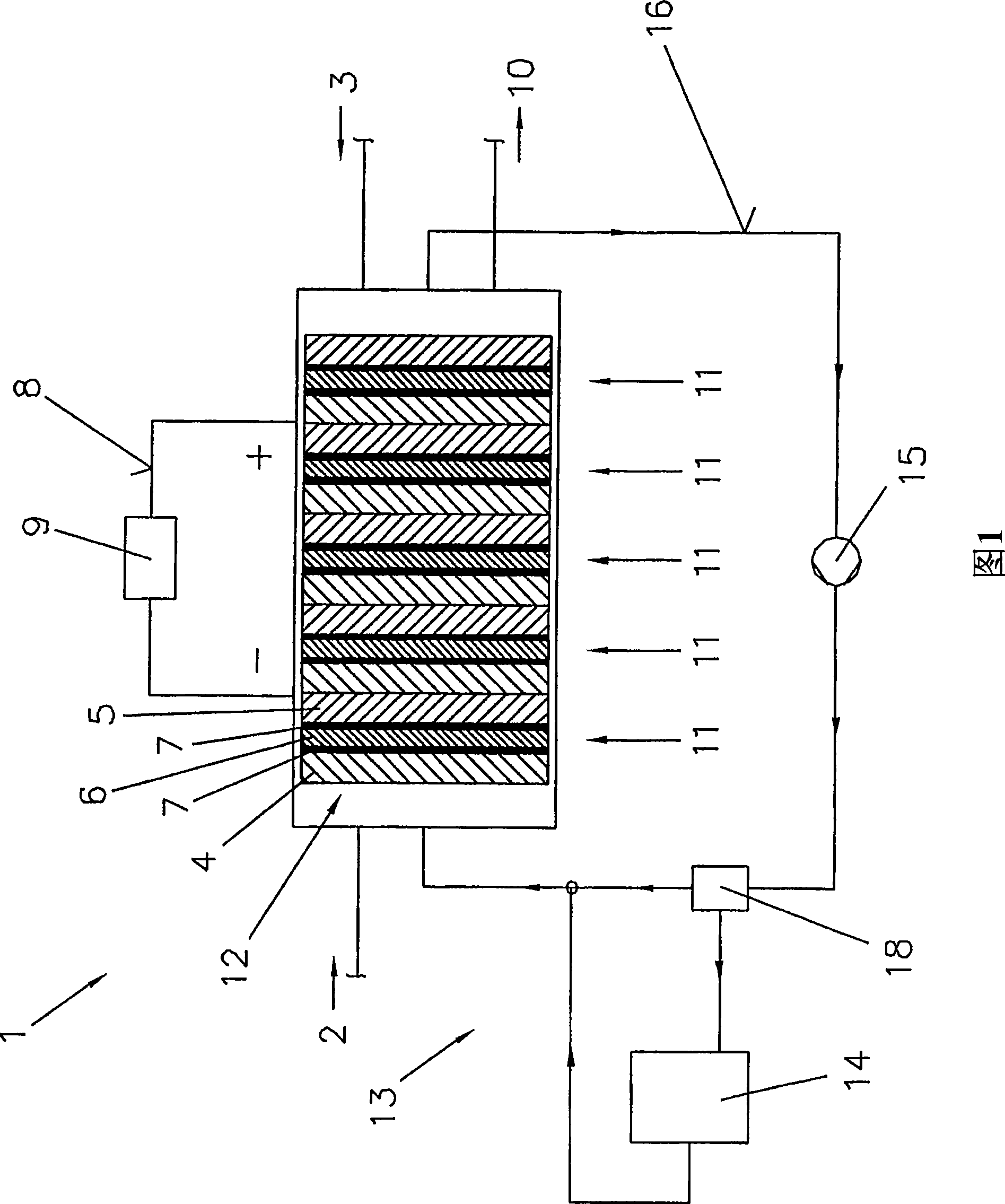

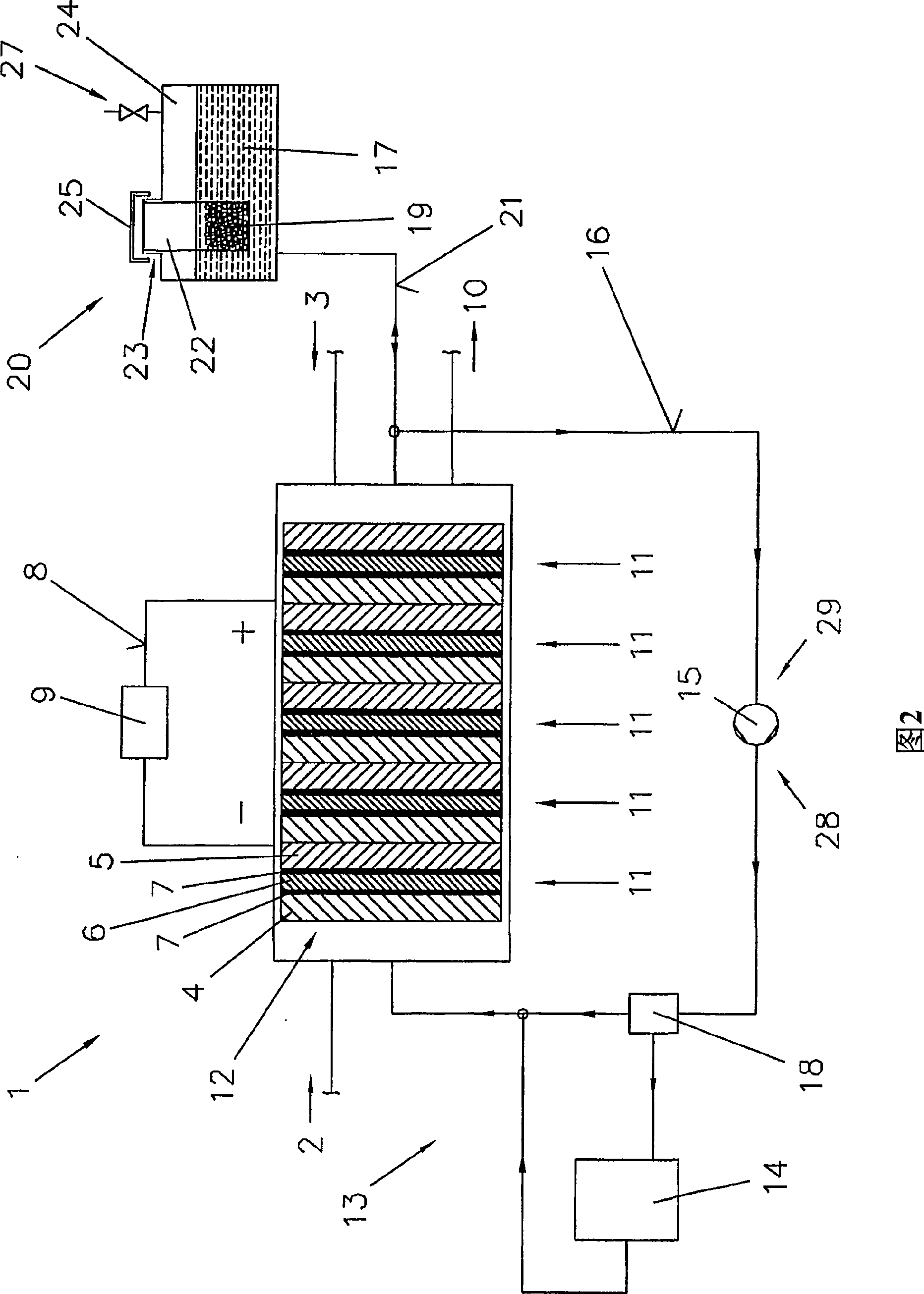

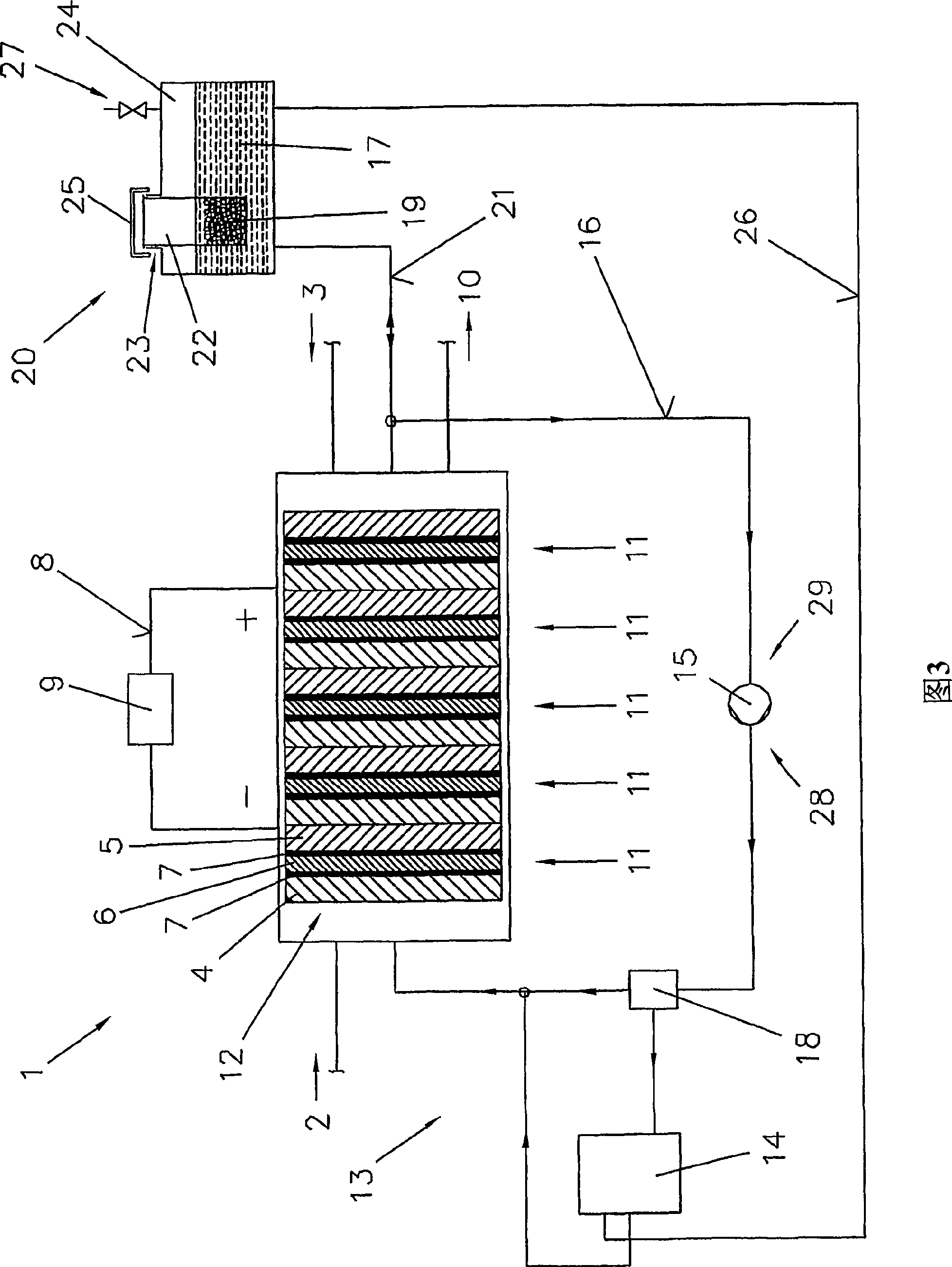

[0033] In FIG. 1 , a fuel cell 1 is shown for generating electrical current from hydrogen 2 and oxygen 3 or air, respectively.

[0034] In general, the fuel cell 1 is an electrochemical current generator that generates electrical current directly from chemical reactions. This is achieved by splitting water by inverse electrolysis, in which the gases hydrogen2 and oxygen3 are formed by the flow of electric current.

[0035] This means that in the fuel cell 1, hydrogen 2 reacts with oxygen 3, thereby generating an electric current. For this, hydrogen 2 is supplied to the anode 4 and oxygen 3 to the cathode 5 , which are separated by an electrolyte 6 . Furthermore, the anode 4 and the cathode 5 are coated on their sides facing the electrolytic solution 6 with a catalyst 7 mainly formed of platinum. In this way, hydrogen 2 can react with oxygen 3 , which takes place i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com