Concrete block repairing and cutting device

A concrete block and coagulation technology, which is applied in the direction of ceramic molding machines and manufacturing tools, can solve the problems of burrs or flashes in batches of concrete blocks, affecting the production progress, affecting the cutting quality of blocks, etc., and avoiding overall cutting The effect of quality, ease of use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

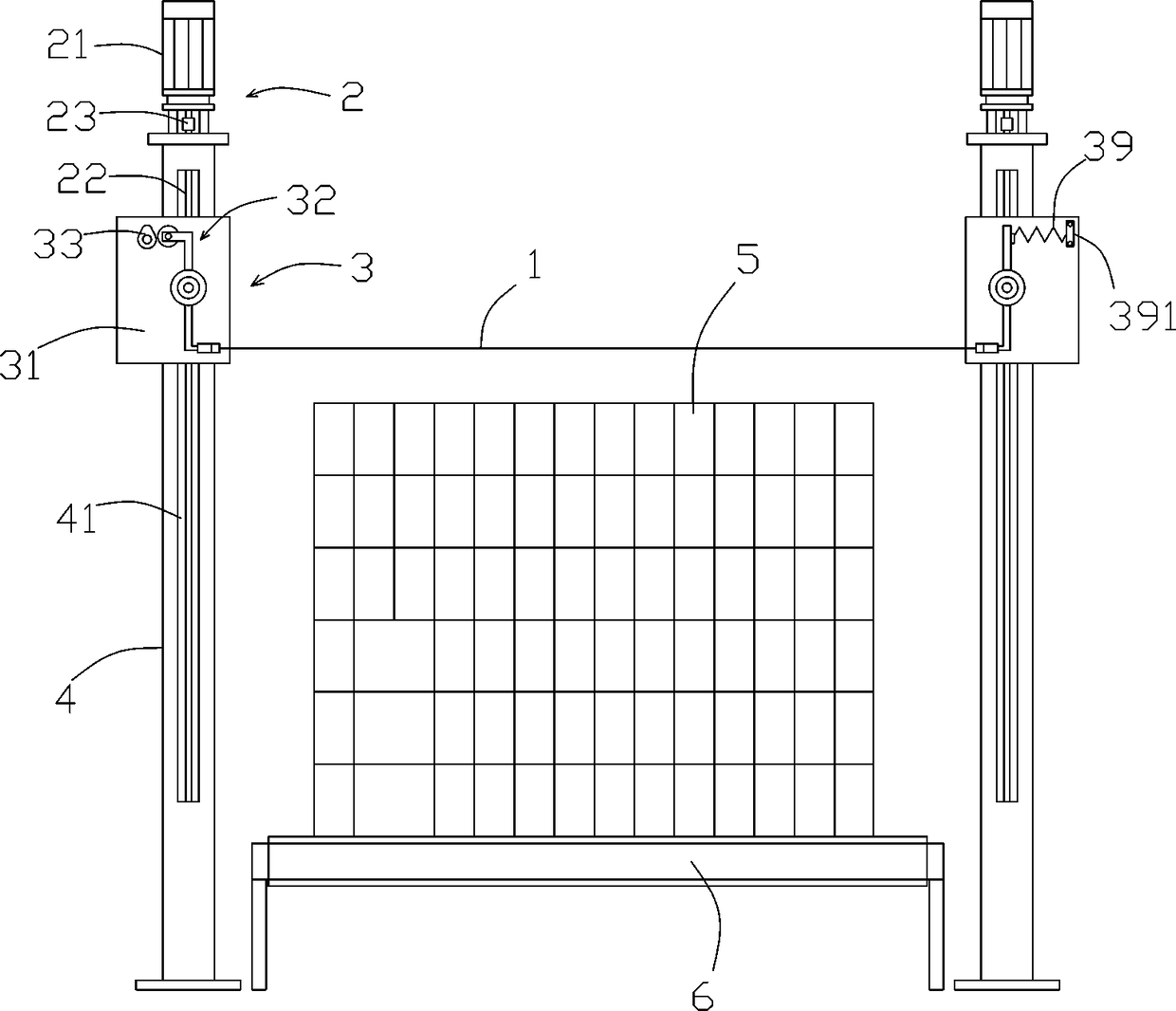

[0021] Such as figure 1 with 4 Shown: a concrete block 5 complementary cutting device, including steel wire 1 and two sets of cutting mechanisms arranged symmetrically on both sides of the concrete block;

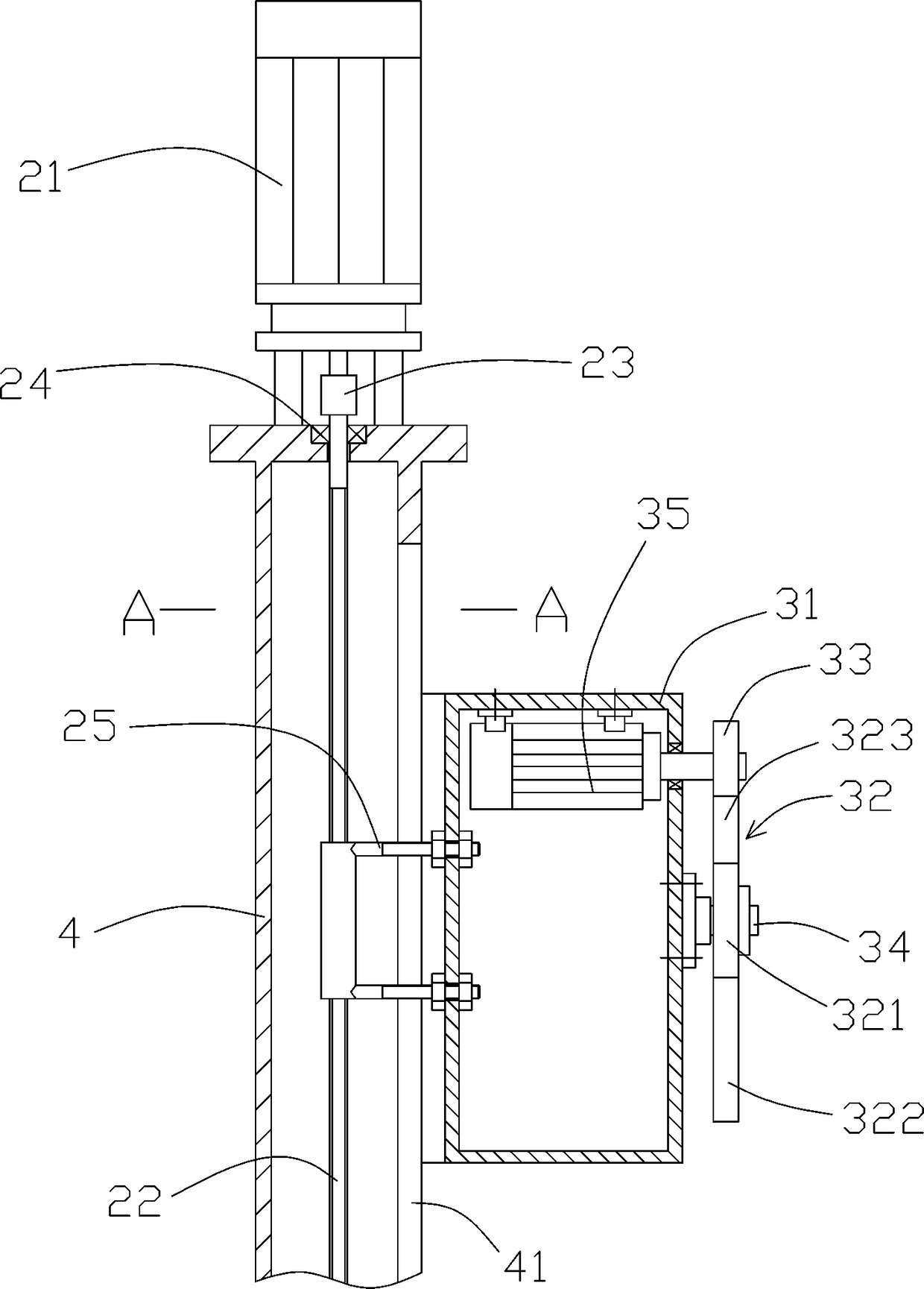

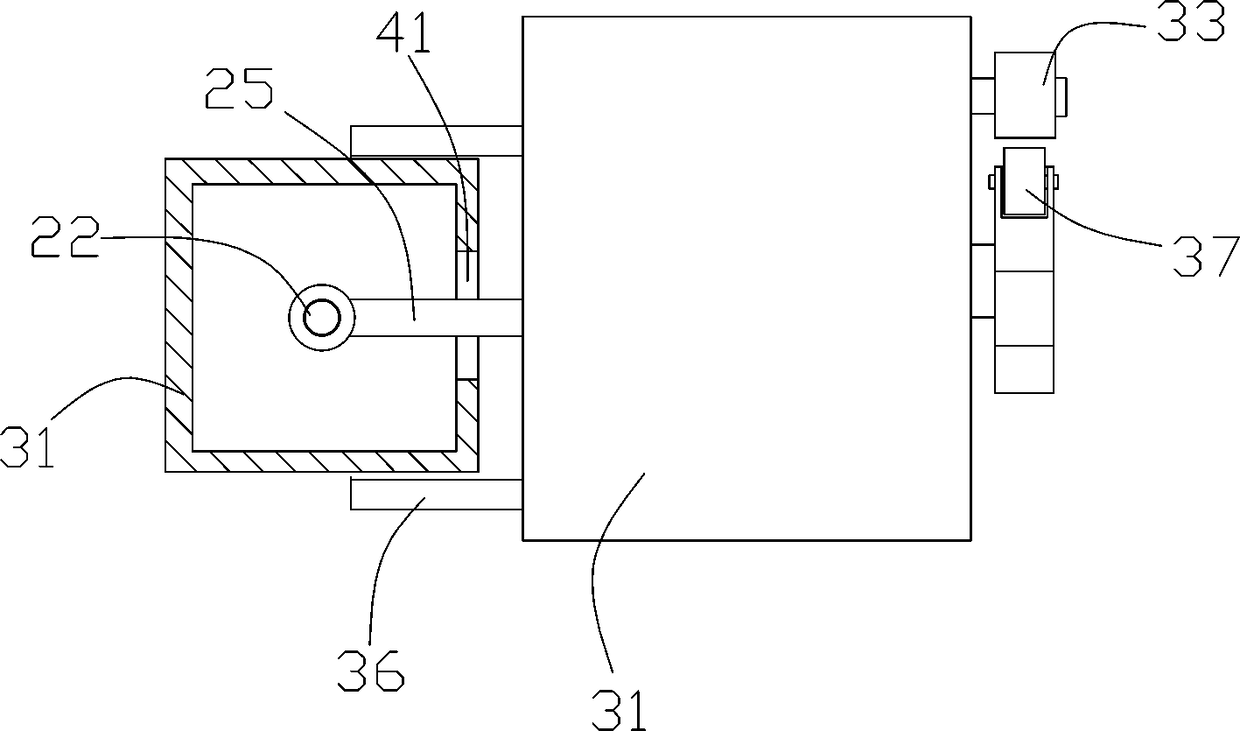

[0022] The cutting mechanism includes a pole 4 and a lifting part 3 and a driving part 2 installed on the pole 4;

[0023] The interior of the pole 4 is hollow, the cross-sectional shape can be square, and one side of the pole 4 has a vertical opening 41;

[0024] The driving part 2 includes a first motor 21 and a ball screw 22 installed on the upper end of the vertical rod 4, bearings 24 are installed on the upper and lower ends of the vertical rod 4, and the two ends of the screw of the ball screw 22 are respectively connected to the upper end of the vertical rod 4 and the lower end of the vertical rod 4. On the bearing 24 at the lower end (the bearing 24 at the lower end of the vertical rod 4 is not shown in the figure), the rotating shaft of the first motor 21 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com