Secondary lifting mechanism for automatically positioning

A lifting mechanism and automatic positioning technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems of intermittent working process, hidden safety hazards, laborious and other problems, and achieve the effect of continuous working process, less repair space and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

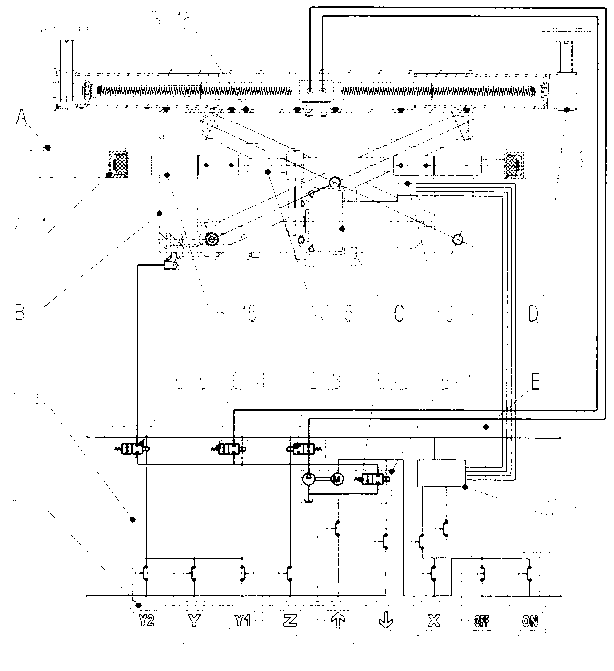

[0032] Such as figure 1 , the secondary lifting mechanism for automatic positioning of the present invention includes a lifting trolley B, a trolley running mechanism C and a bracket extension mechanism D, an automobile correction machine platform or an automobile lifting unit lifting platform A, fixed on the inner frame of the automobile correction machine platform A The running track A-1 is composed of parallel channel steel on both sides or between the lifting platform of the car lift unit.

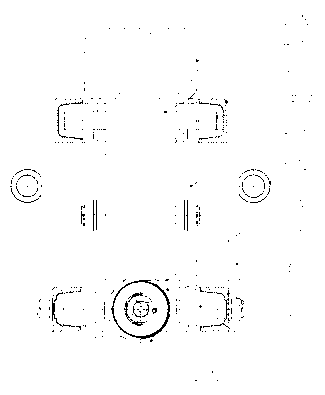

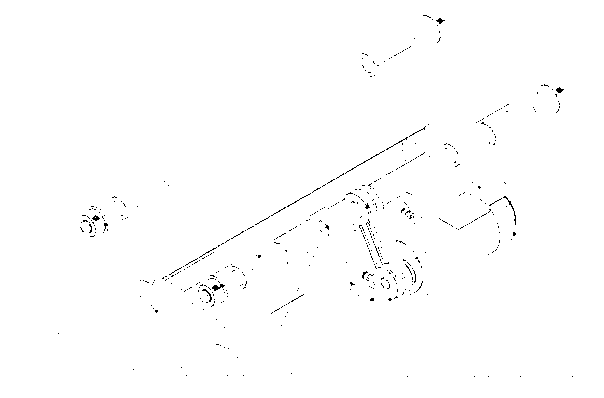

[0033] Such as figure 2 and image 3 , the lifting trolley B includes a lower frame B-1, an upper frame B-2, a lifting roller B-3, a scissor arm B-4, a booster frame B-5 and a lifting cylinder B-6. The lower frame B-1 is composed of two channel steels with opposite notches and left and right end plates, the left end plate is slightly higher than the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com