Horizontally-concealed type automatic robot ultrasonic diagnostic machine with trolleys moving on inner-outer rings

A technology of moving trolleys and robots, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, the use of sound waves/ultrasonic waves/infrasonic waves for material analysis, and instruments. High labor intensity, small footprint and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

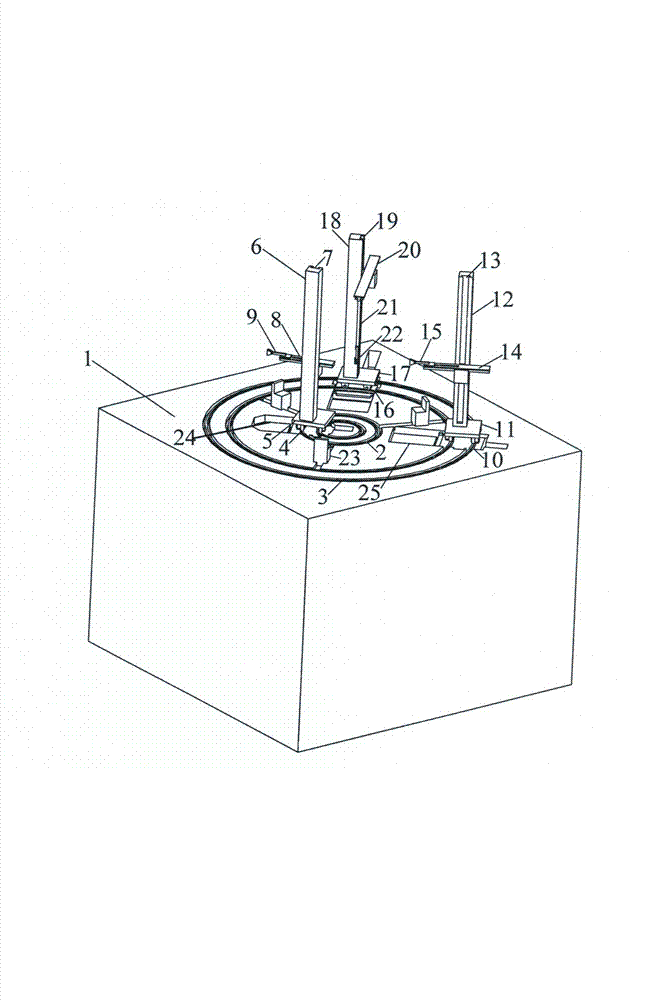

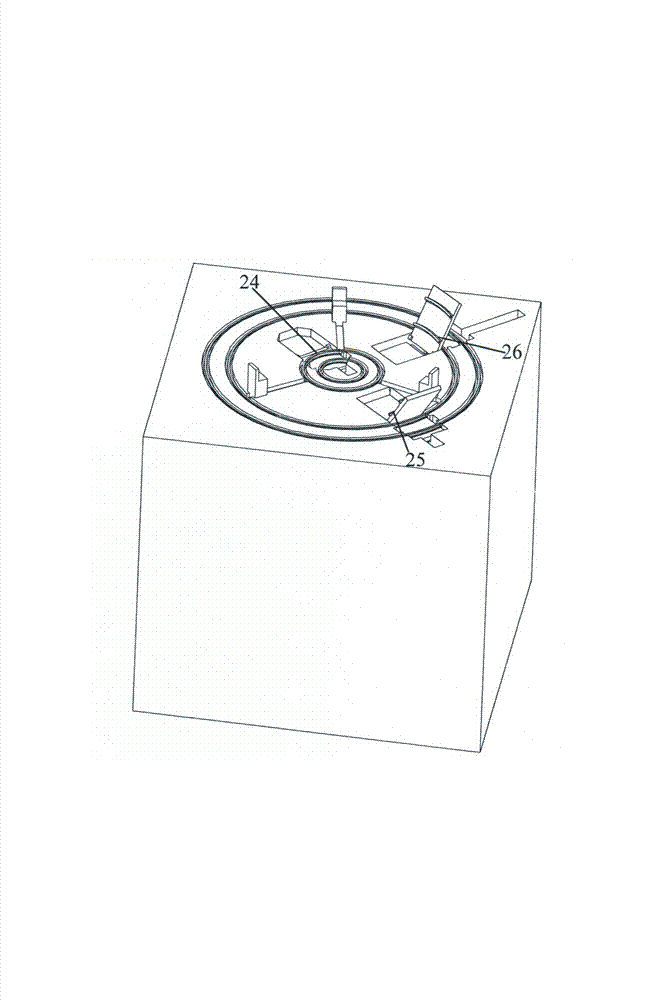

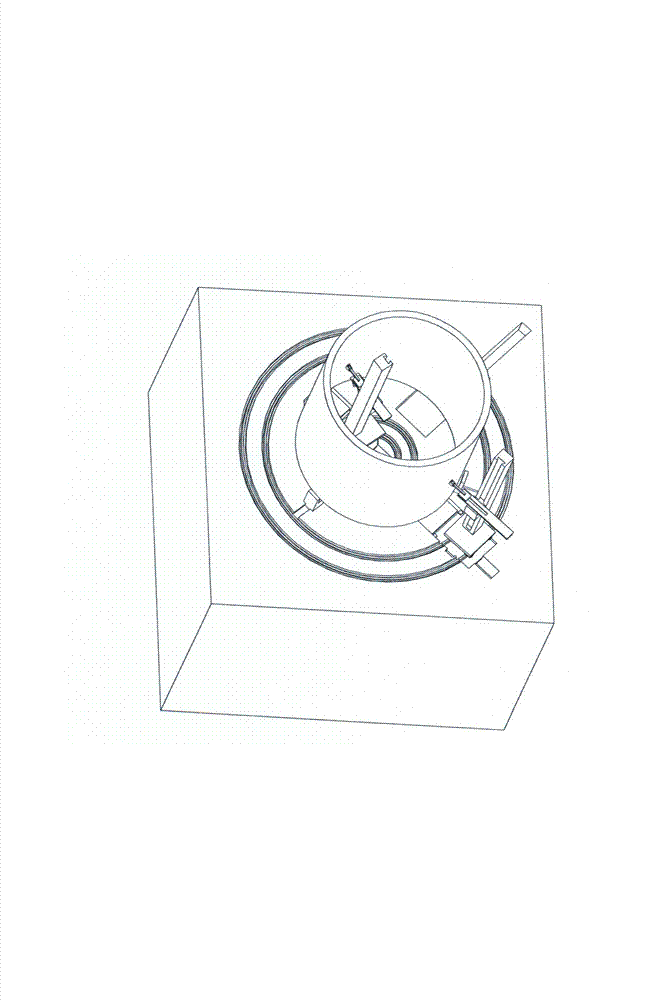

[0021] The present invention will be further described in conjunction with the accompanying drawings and embodiments as follows. like figure 1 As shown, the ultrasonic automatic flaw detection machine of the horizontal hidden type inner and outer annular moving trolley robot of the present invention consists of a base with a working platform 1 on the top, an inner circular guide rail 2, an outer circular guide rail 3, and a movable supporting plate for the inner caisson docking guide rail. 4. Inner detection trolley base 5, inner detection trolley column 6, inner detection trolley vertical guide rail 7, inner detection trolley beam 8, inner probe 9, first outer caisson docking guide rail movable support plate 10, first outer detection trolley base Seat 11, first outer detection trolley column 12, first outer detection trolley vertical guide rail 13, first outer detection trolley crossbeam 14, first outer probe 15, second outer caisson docking guide rail movable supporting plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com