Mechanical anti-swing bridge crane for transferring and cleaning distillers' grains

A bridge crane, anti-swing technology, applied in the cleaning method using tools, load block, transportation and packaging, etc., can solve the problems of poor telescopic flexibility and movement stability, unreasonable crane layout structure, and inability to assist lifting and positioning, etc. , to achieve the effect of exquisite and concise overall design, easy to drive cleaning operations, and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings in the embodiments of the present invention. In the description, it should be understood ", "Right" and other indicated orientations or positional relationships are only corresponding to the drawings of the present invention. In order to facilitate the description of the present invention, they do not indicate or imply that the referred device or element must have a specific orientation:

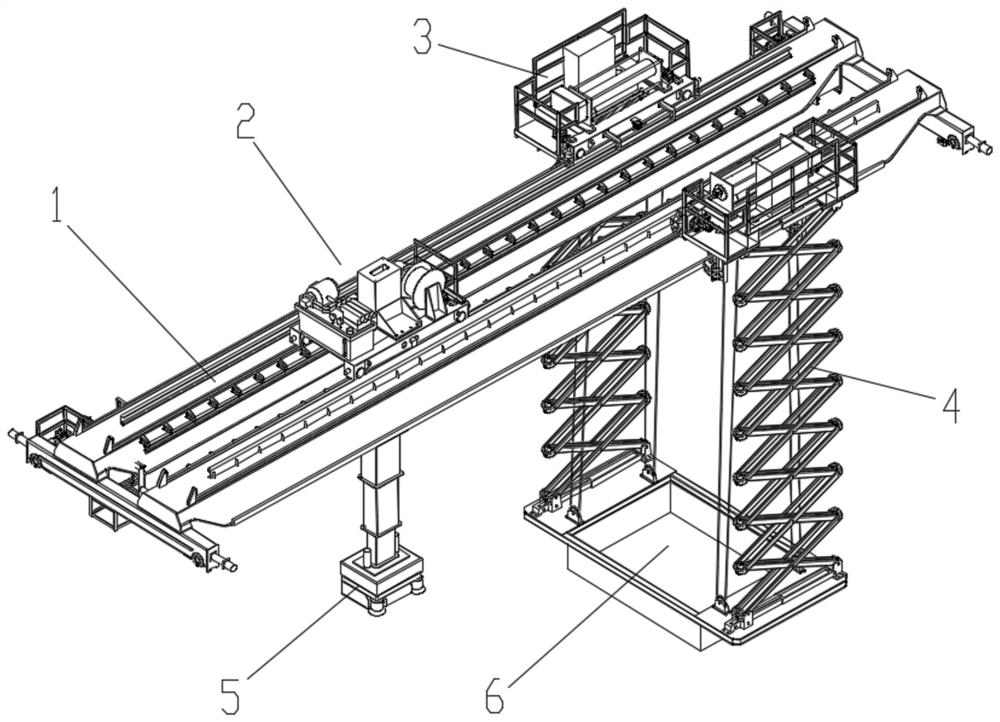

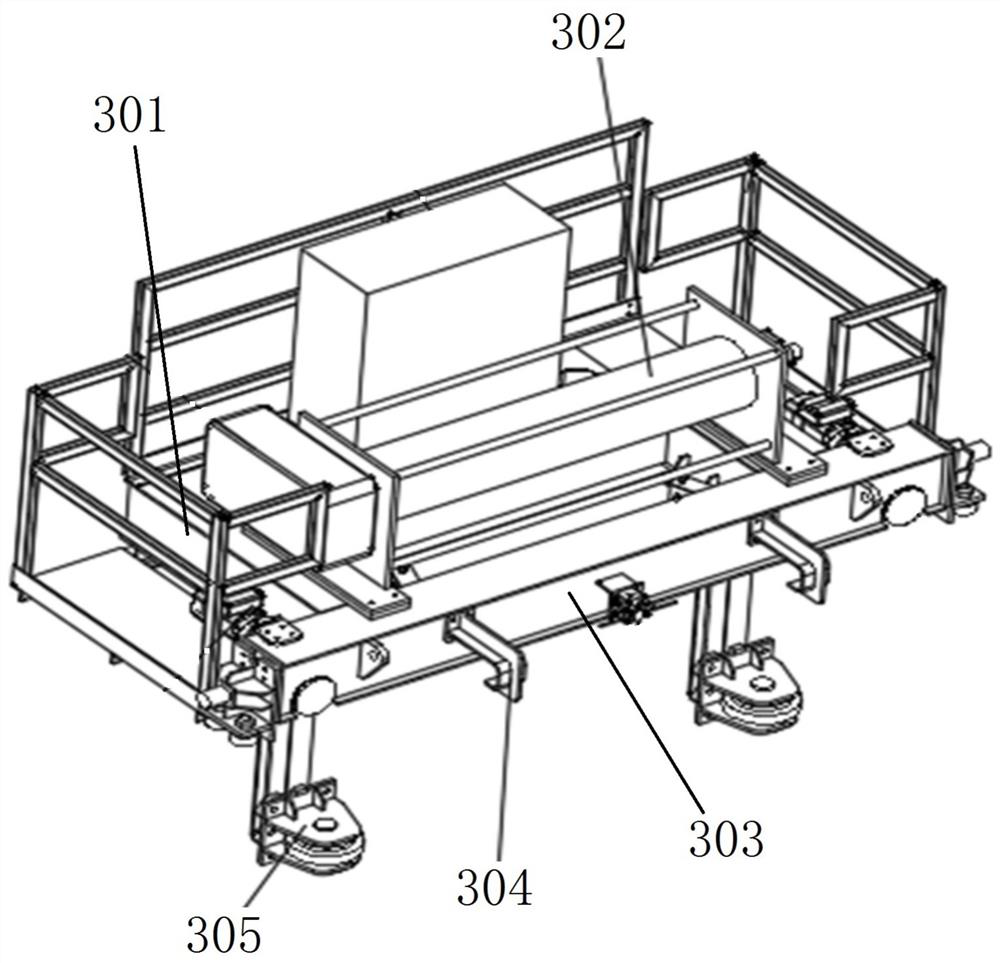

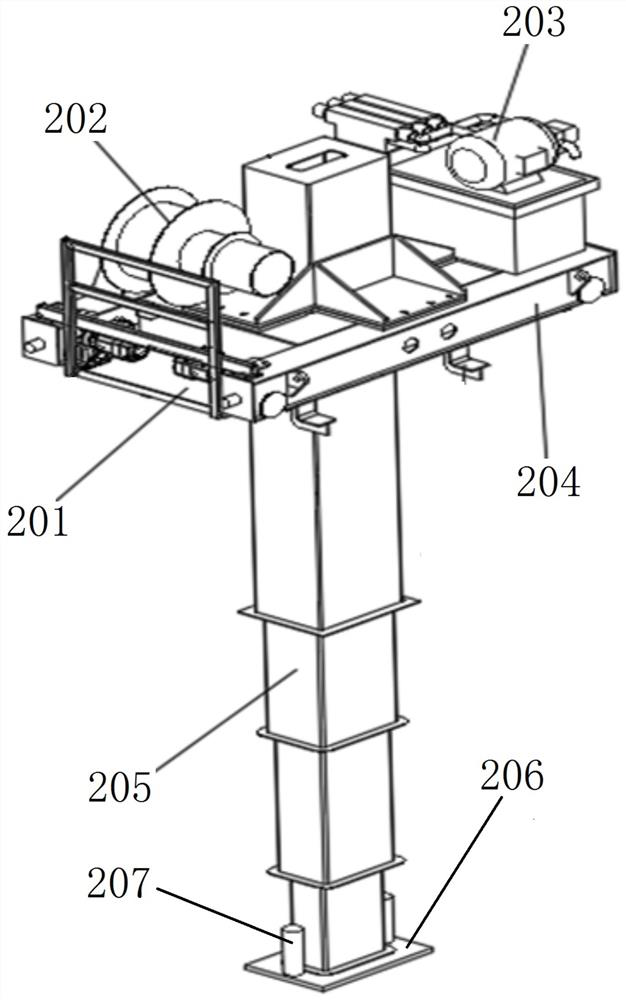

[0040] combined with Figure 1-16 The mechanical anti-sway bridge crane for distiller's grains transfer and cleaning includes a cleaning device 5, a transfer tank 6 and a bridge frame 1. The bridge frame 1 includes two spaced and side-by-side main girders 101, between the two main girders 101 and between the two The outer side is respectively equipped with a middle trolley 2 and two eccentric trolleys 3 which can be moved and positioned along the main beam 101. The tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com