High-strength, low-temperature, and thick-gauge hot-rolled plate strip coil shape control method

A control method and thick gauge technology, which are applied in the coil shape control of high-strength, thick gauge hot-rolled strips and low temperature fields, can solve the problems of coil quality dislocation, etc., so as to improve product quality, increase efficiency, and eliminate dislocation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

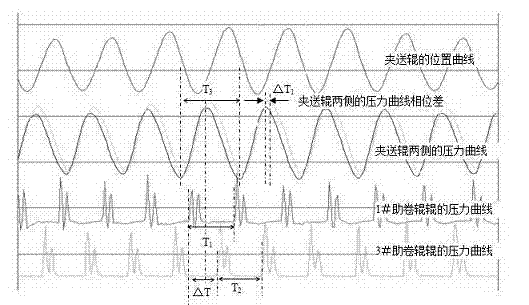

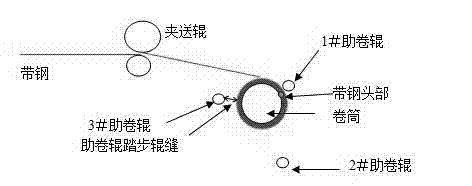

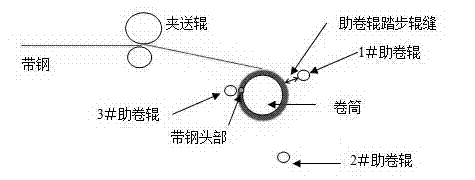

[0033] see figure 2 , 3 , a method for high strength, low temperature, thick gauge hot-rolled strip volume control, the concrete steps of the method are as follows,

[0034] 1) Before the strip steel arrives at the coiler, the pinch roller and the auxiliary winding roller are in the roll gap control mode;

[0035] 2) After the pinch roll bites the strip, the pinch roll switches from the roll gap control mode to the pressure control mode;

[0036] 3) During the first few laps of strip steel coiling, 1#, 2#, 3# auxiliary winding rollers are in the pressure or roll gap control mode;

[0037] The above control is the same as the prior art, and the invention points of this technology are as follows:

[0038] 4) After the first few laps of strip steel on the reel (X 0 The number of laps is manually set), 2# winding-assisting rollers are all opened, so that the roll unloading trolley can rise up, ready to unload, 1#, 3# winding-assisting rollers enter the stepping control mode, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com