Method for utilizing two cranes on saturation diving support vessel to mount vertical pipe

A technology of double cranes and standpipes, which is applied in drilling pipes, casings, and earthwork drilling and mining, can solve the problems of saturated diving support ships, unsuitable control of construction progress, and shortage of ship resources, etc., to improve work efficiency and economy. Benefits, reduced possibility of saturation diving support vessel standby, effect of reduced construction risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

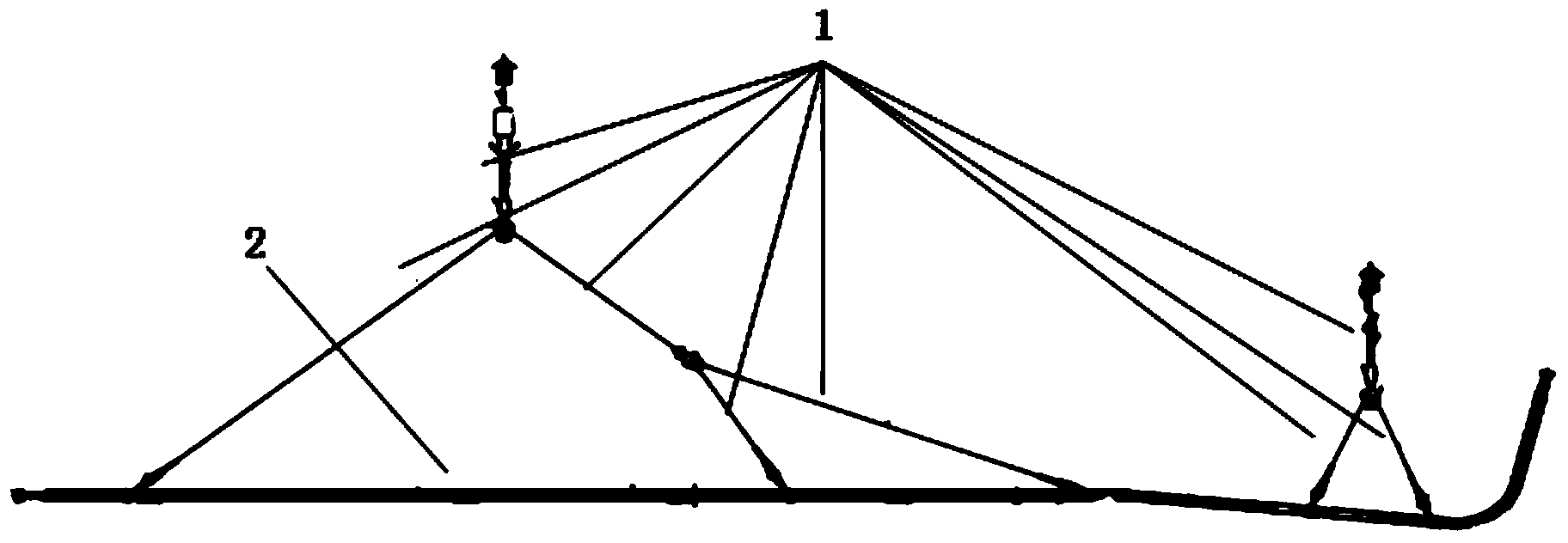

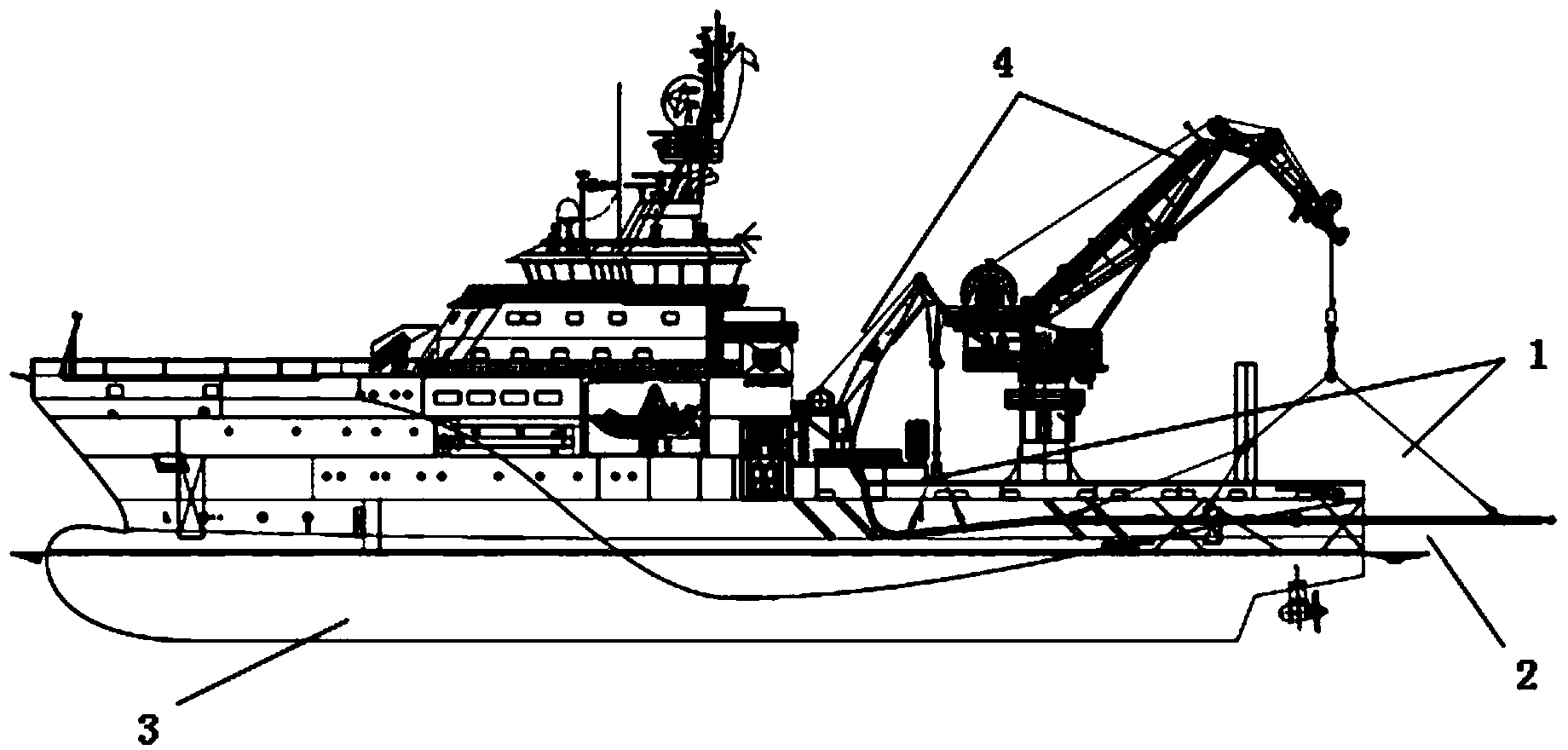

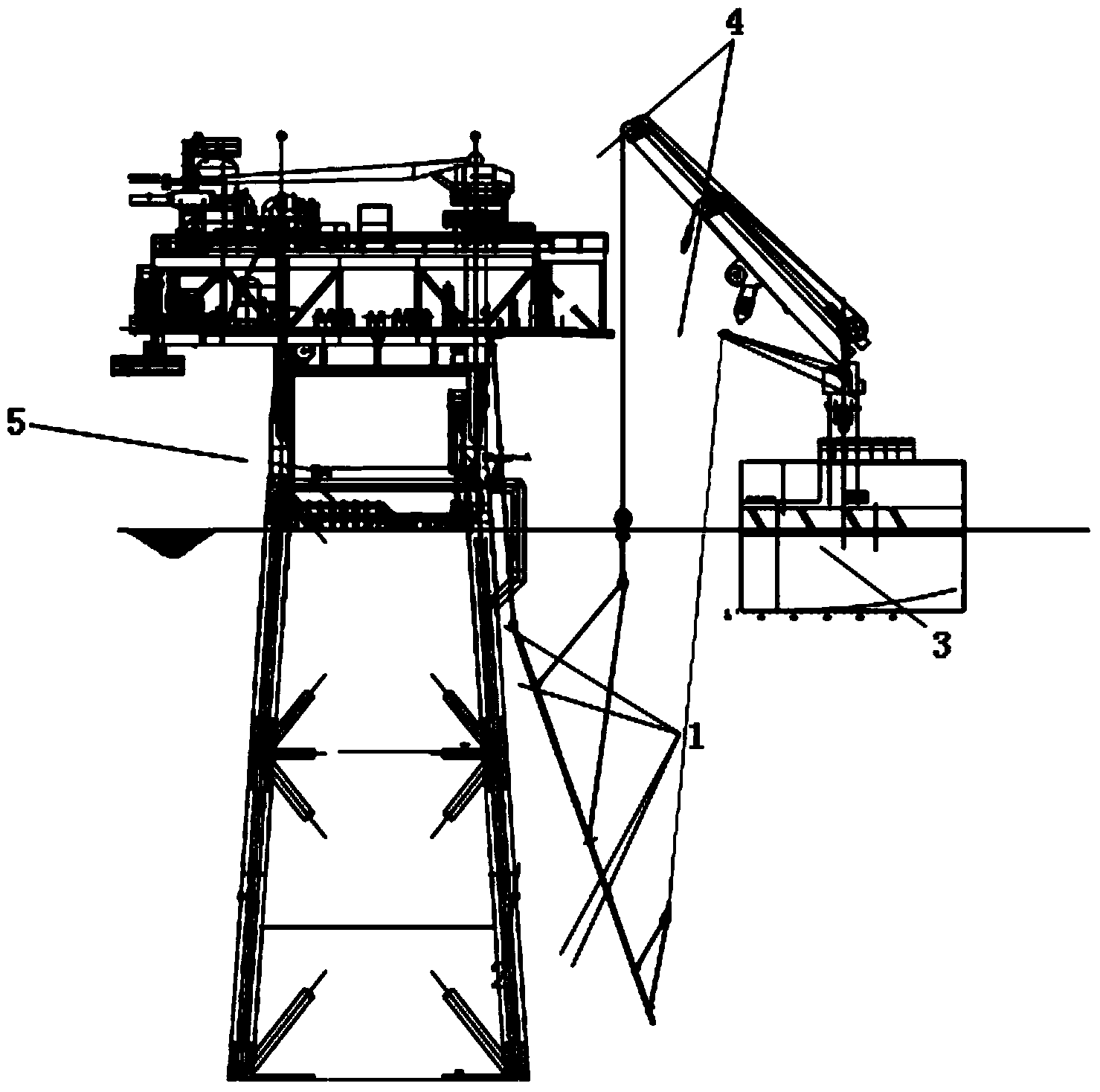

[0042] Before the riser of the present invention is installed, the winch 5 needs to be installed on the platform according to the design requirements, and several lifting points are installed by welding, and the direction of the wire rope of the winch 5 can be changed through the lifting points, so that it can be changed as needed when the riser 2 is transferred. The direction of the riser 2; since the transfer of the riser 2 also has high requirements on the sea conditions, only under good sea conditions can the saturation diving support ship 3 and the barge safely approach each other to complete the lifting and transfer of the riser 2.

[0043] The offshore installation work of the riser of the present invention adopts the following installation steps:

[0044] Step 1, transfer of the operator from the saturation diving support vessel 3 to the barge

[0045] The barge transporting the riser 2 chooses a good place to anchor, and adjusts its heading; the saturation diving supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com