Beam-slab framework early removal construction method

A construction method and formwork technology, applied in formwork/formwork/work frame, formwork treatment, construction material treatment, etc., can solve the problem that the stress state is not as good as the slab-assisted floor, the floor slab is demolished early, and the application scope is narrow, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0117] [Example]: A building with a 7-story frame structure, a room with a bay of 4.2×6m, a roof thickness h=100mm, roof reinforcement ∮8@150, and a concrete design strength of C25. Early demolition of the formwork is carried out. The specific implementation methods are as follows:

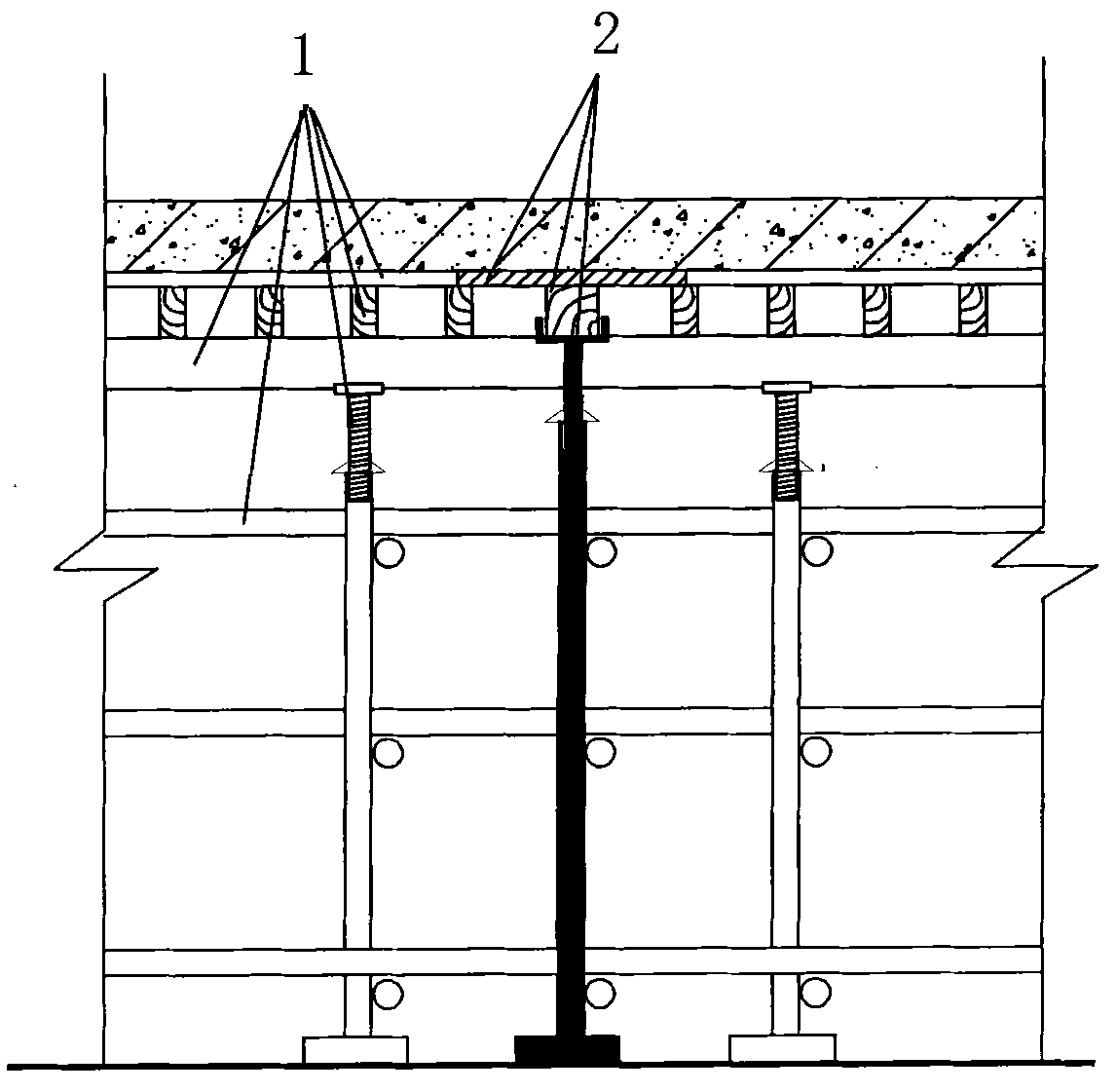

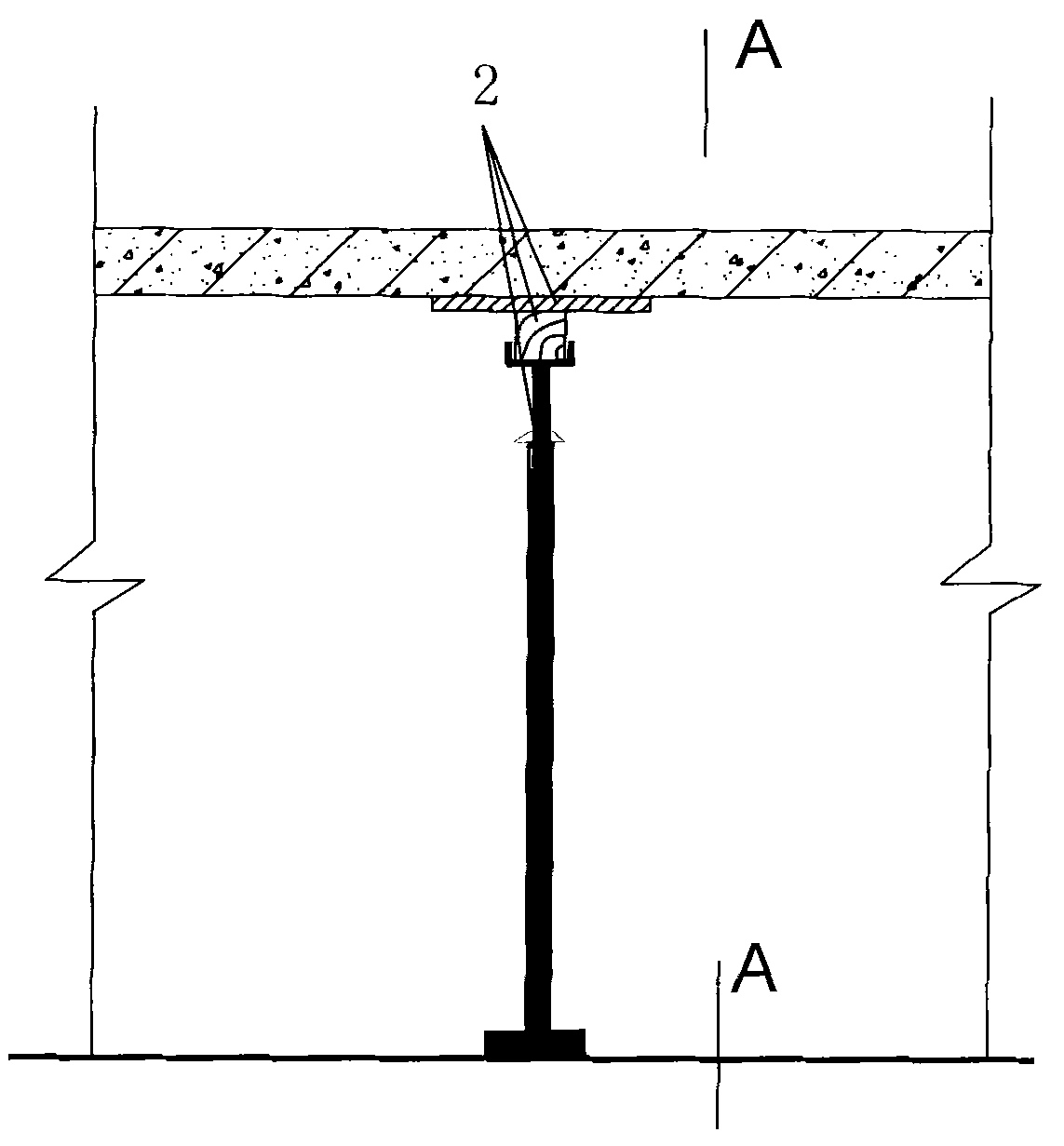

[0118] 1. Perform cross-change processing

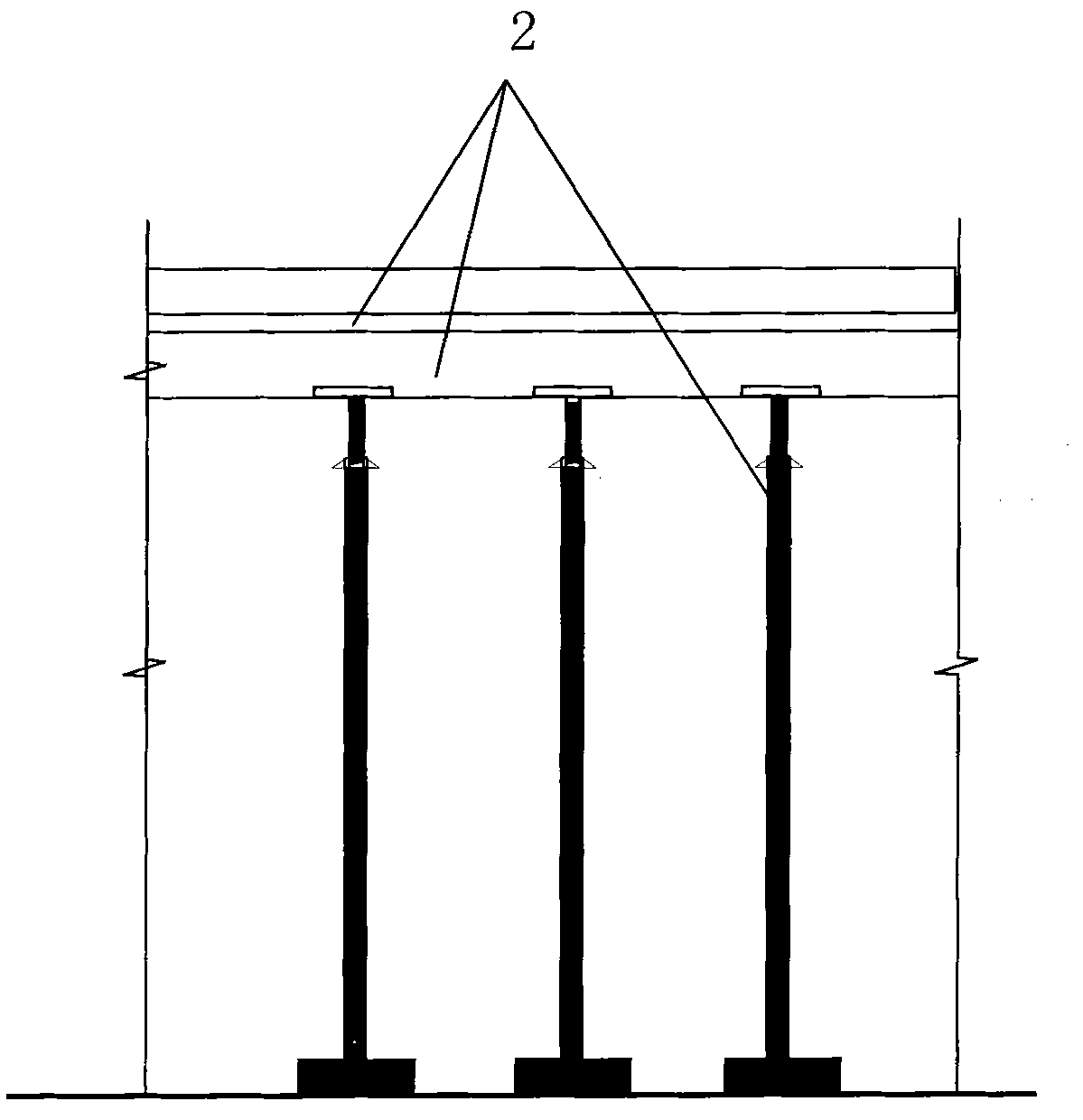

[0119] A 10CM*10CM wooden square is set in the short direction at the middle of the bottom of the 6m span of the floor as the sub-keel, and 4 vertical poles are set at the bottom of the sub-keel as supports, and the distance between the poles is 1400mm. Make the 4.2×6m two-way slab into a 3×4.2m two-way slab formwork removal structure.

[0120] 2. Determine and calculate the early demolition strength and early demolition time

[0121] The structural parameters of the 3×4.2m span floor, span L=3m, plate thickness h=100mm, reinforcement As=335mm 2 , compared with the attached table 1 of the early demolition construction application manual of the formwork...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com