Prefabricated pile cap for composite foundation

A technology of prefabricated assembly and composite foundation, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems that the advantages of prefabricated piles cannot be fully utilized, the connection of prefabricated piles is unreasonable, and the quality is difficult to guarantee, etc., so as to facilitate construction , Ensure the correct connection and reduce the rental cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments of the description:

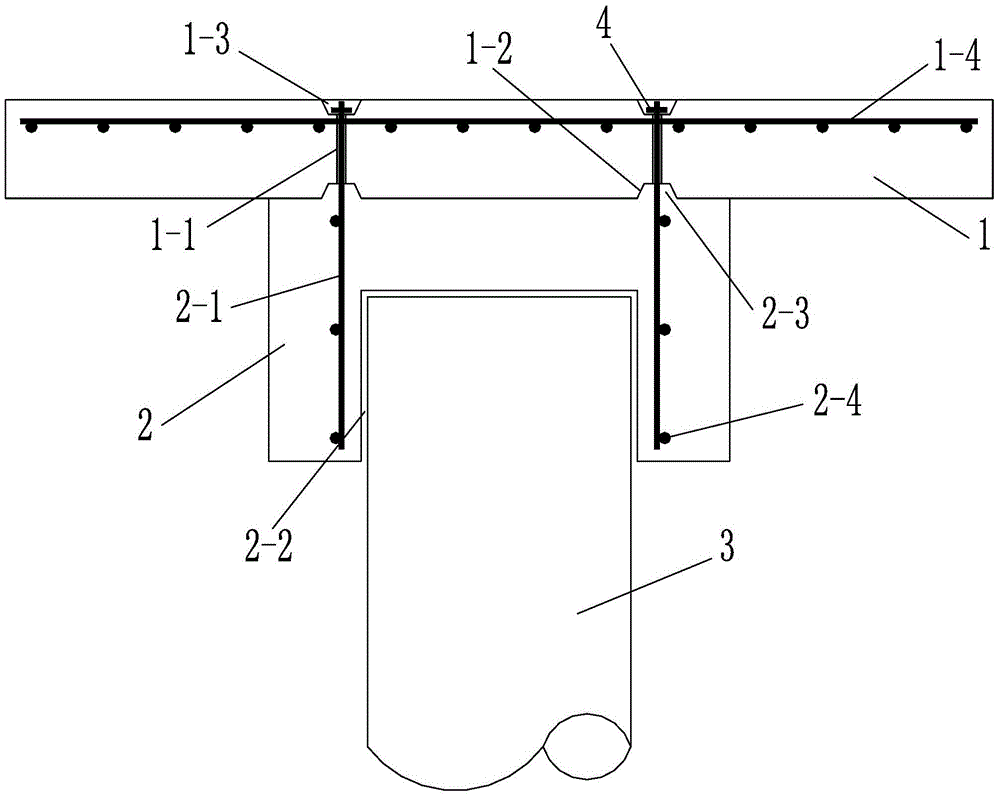

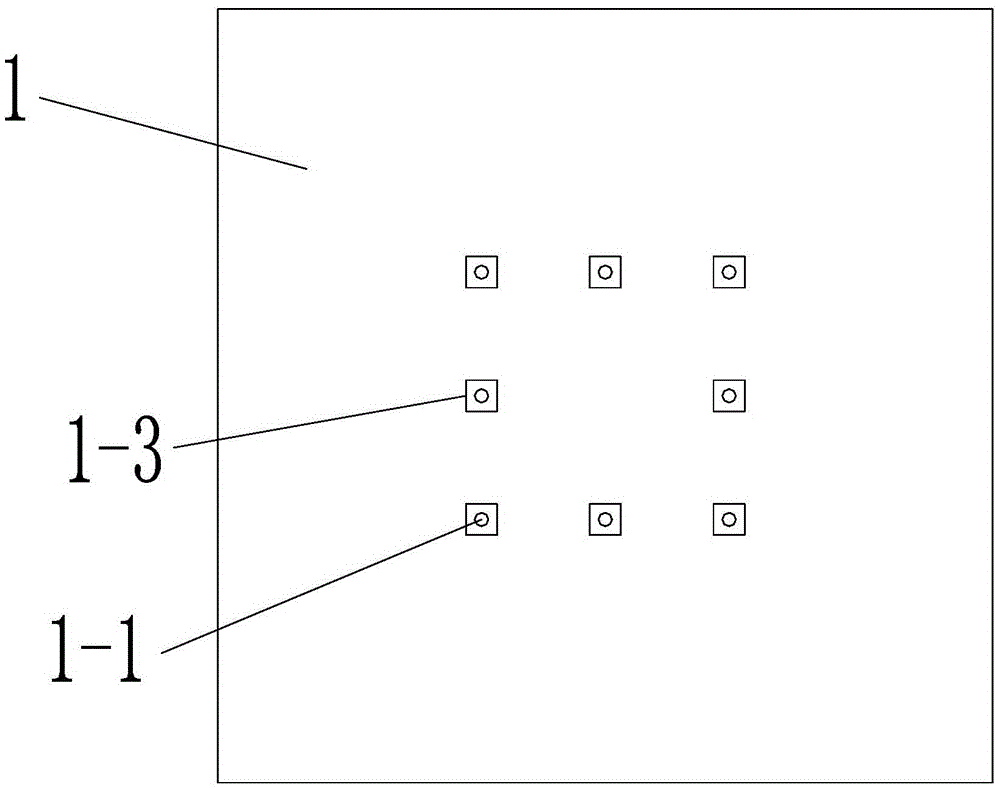

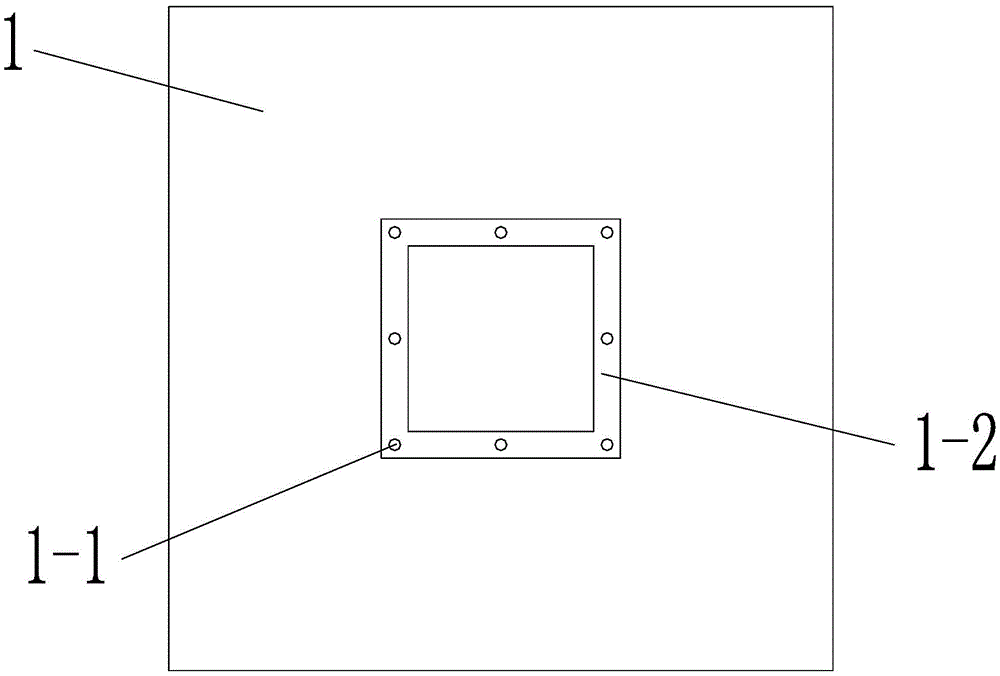

[0021] Such as Figures 1 to 8 Shown is a schematic diagram of an embodiment of a prefabricated assembled pile cap for a composite foundation provided by the present invention.

[0022] A prefabricated pile cap for a composite foundation, which includes a top plate 1 and a fixing kit 2 connected to the lower side of the top plate 1;

[0023] Several locking rods 2-1 are vertically arranged in the fixing kit 2, and each locking rod 2-1 extends out of the upper end surface of the fixing kit 2, and the lower end of the fixing kit 2 is provided with a hole for setting the prefabricated pile 3. Blind hole 2-2. The size of blind hole 2-2 should be slightly larger than the outline size of prefabricated pile 3. The shape of the blind hole 2-2 can be circular or rectangular, which matches the shape of the prefabricated pile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com