Construction method of cone-shaped top structure of large silo

A construction method, conical technology, applied in the direction of building type, large-capacity bulk material storage, construction, etc., can solve the problems of a large number of scaffolding steel pipes, affecting the construction period, and delaying the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

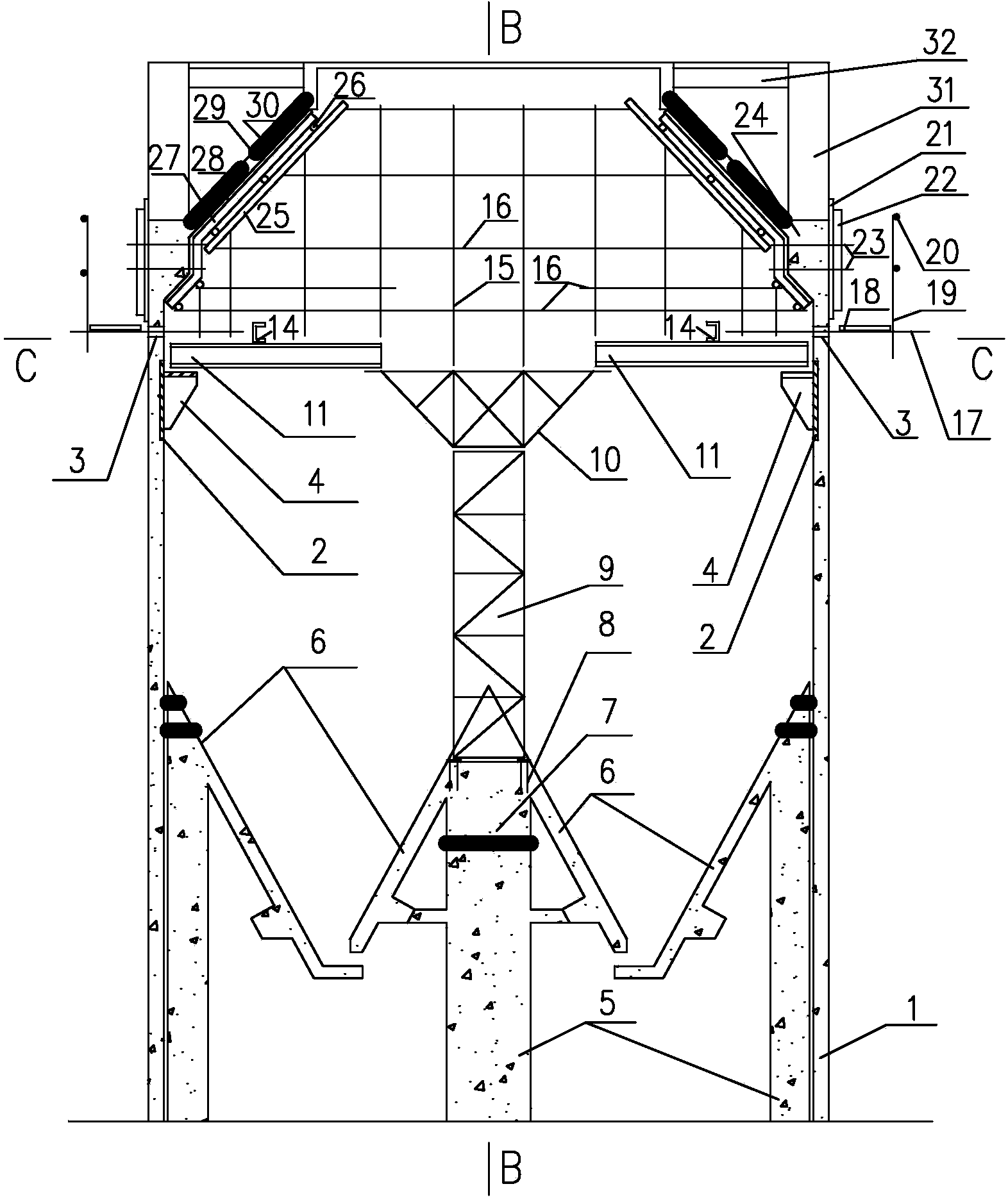

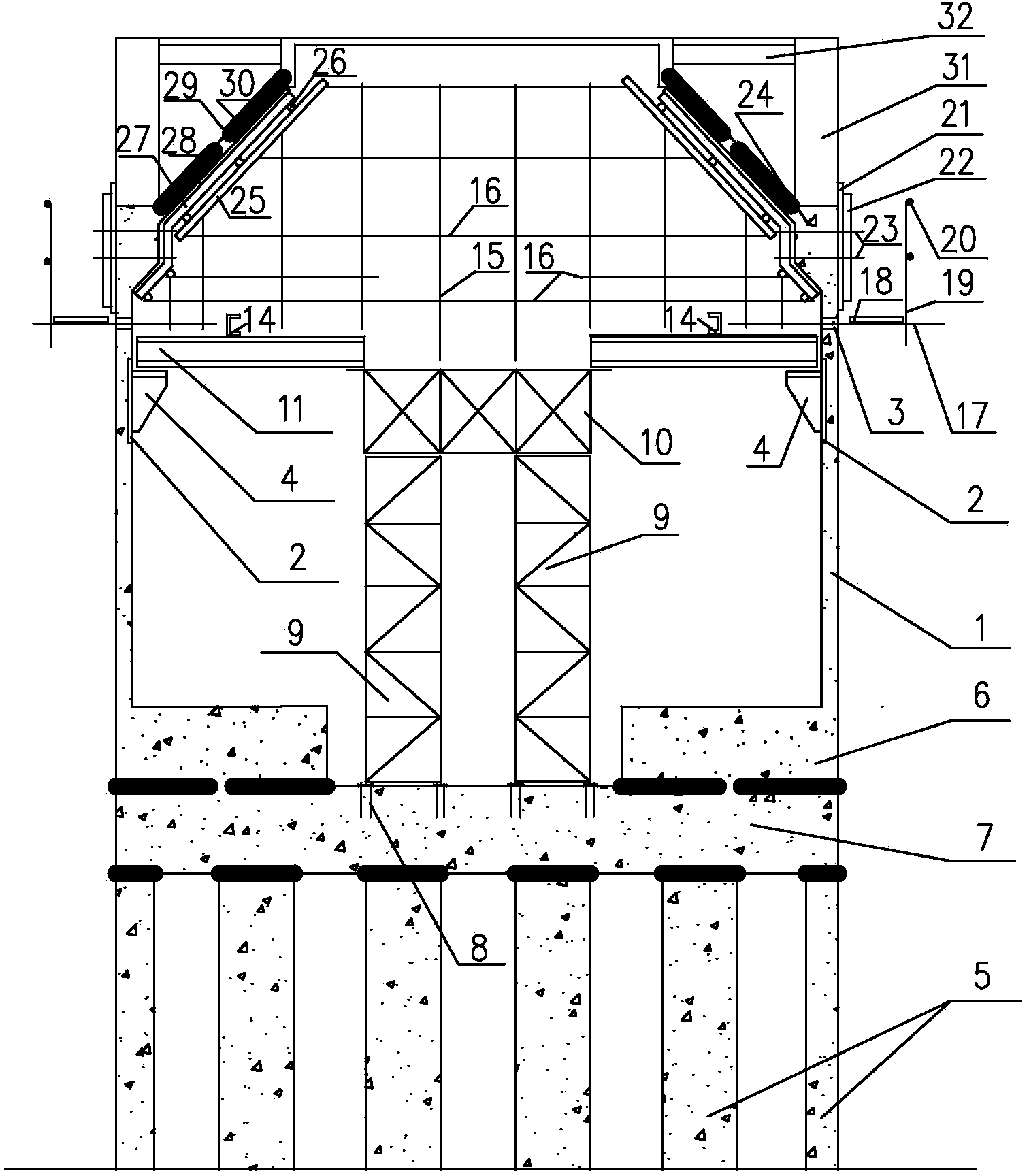

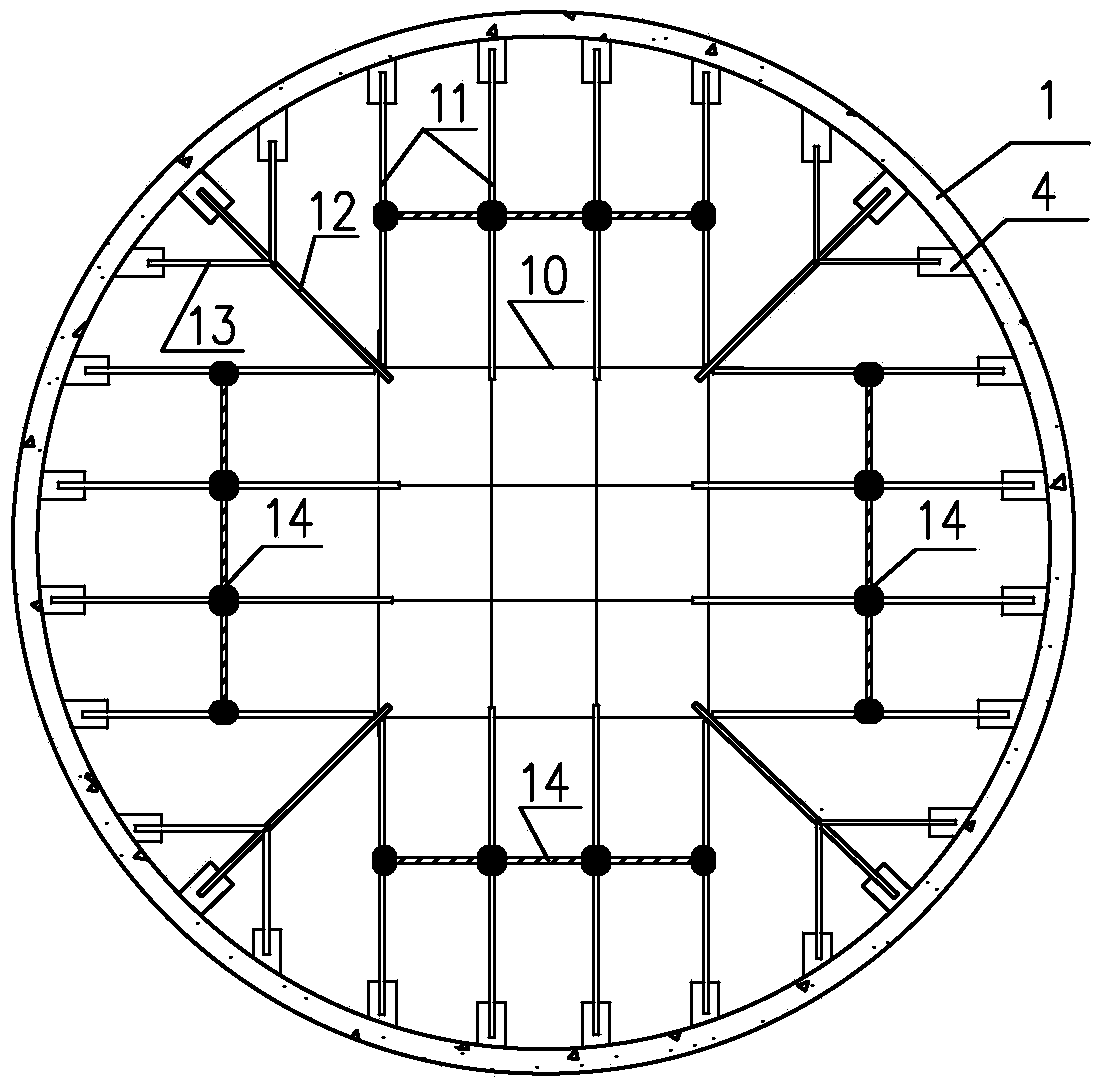

[0033] like figure 1 , 2 , Shown in 3, the construction method of large silo conical roof structure of the present invention comprises the following steps:

[0034] 1. In the sliding form process of the wall of a large silo, a plurality of embedded parts 2 are embedded on the inner wall of the wall 1 close to the height of the silo roof. A plurality of reserved holes 3 are set on the wall of the cylinder, and the plurality of reserved holes 3 are at the same height, and the plurality of reserved holes 3 are evenly arranged along the circumference of the cylinder wall 1, and the sliding form of the cylinder wall is suitable for close to the top of the warehouse. Stop sliding after reaching the height and remove the sliding form device. According to the size of the silo and the structural load on the roof of the silo, select steel plates and anchor reinforcement materials that meet the requirements to prefabricate the embedded part 2 in advance. The structure of the embedded pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com