Construction method of middle partition of urban underground comprehensive pipe gallery

A technology of integrated pipe gallery and construction method, which is applied in underground chambers, underground transportation, earthwork drilling and mining, etc., can solve problems such as difficulties in the transportation process, prolonging the overall construction period of the project, and inconvenient transportation, so as to overcome hidden dangers in operation safety and reduce The total construction period and the effect of ensuring the quality of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

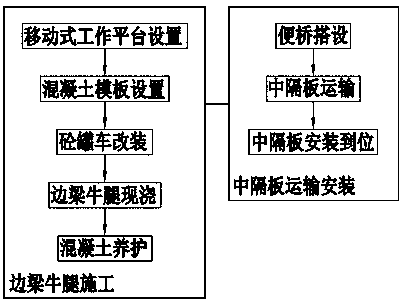

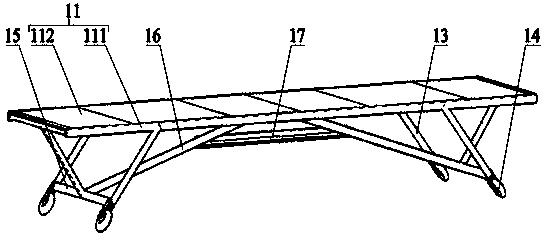

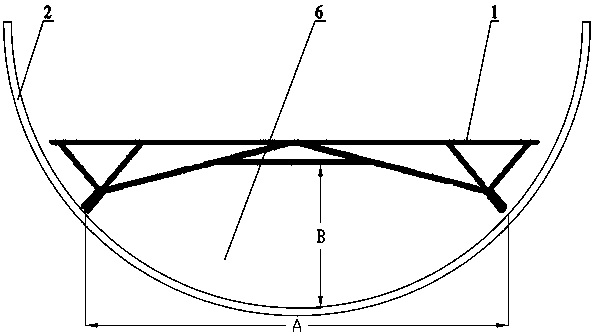

[0037] Such as figure 1 As shown in the figure, a construction method for the middle partition of the urban underground comprehensive utility gallery includes the following steps: S1: Construction of side beam corbels: after the handover of the civil works, set the side beam corbels at the installation position of the middle partition to support the middle partition ;S2: Transportation and installation of the partition board: transport the partition board from the outside of the tunnel 6 to the installation location and install it in place, wherein, S1 includes the following steps: S1.1: Mobile working platform 1 setup: set up the working platform in the pipe gallery 1. The working platform 1 includes roller assemblies on both sides along the width direction of the tunnel 6, and the two roller assemblies abut against the arc-shaped side walls of the shield prefabricated segment 2 respectively, and are formed at the bottom of the working platform 2. 1.0-1.8m clear height passag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com