Rapid installation method of crane light rail sliding conducting wire

An installation method and trolley line technology are applied in the directions of transportation and packaging, load hoisting components, etc., which can solve the problems of hidden safety hazards, low operation efficiency, and large operation risk factor, and achieve the improvement of operation efficiency, safety, and safety. The effect of speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

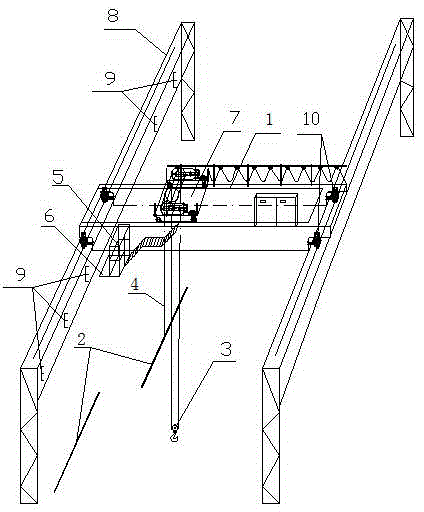

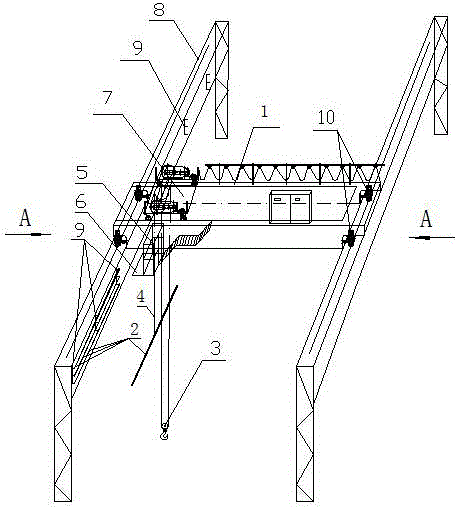

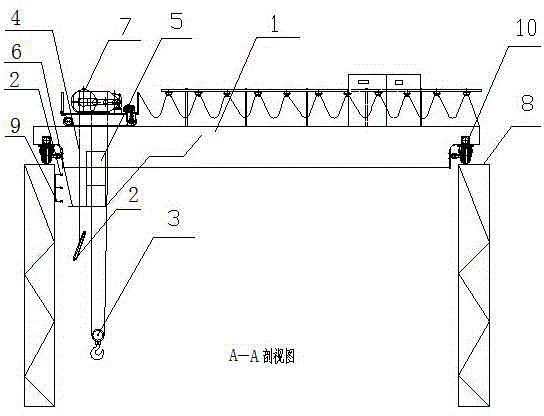

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] In the figure, a quick installation method of the trolley line of the traveling light rail of the present invention includes the following construction steps:

[0021] Step 1. According to the load of the installed and debugged crane 1, lay the temporary power supply cable of the crane to ensure the normal operation of the crane 1; use the crane 1 to lift the light rail trolley line 2 to be installed to the bottom of the installation site;

[0022] Step 2 Fix one end of the lifting belt 4 on the small driving hook 3, and put the other end of the lifting belt 4 until it touches the ground. Before fixing the lifting belt 4, adjust the height of the small driving groove 3 so that the small driving groove 3 will not Affect the hoisting and installation of light rail trolley line 2;

[0023] Step 3 Set up the work platform 6 on the side of the crane receiver mainten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com