Geopolymer crack-resisting artificial stone and preparation method thereof

A geopolymer, artificial stone technology, applied in clay preparation devices, chemical instruments and methods, manufacturing tools, etc., can solve the problems of easy aging of resin, unusable products, poor weather resistance, etc., achieve good weather resistance and reduce raw material costs. , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

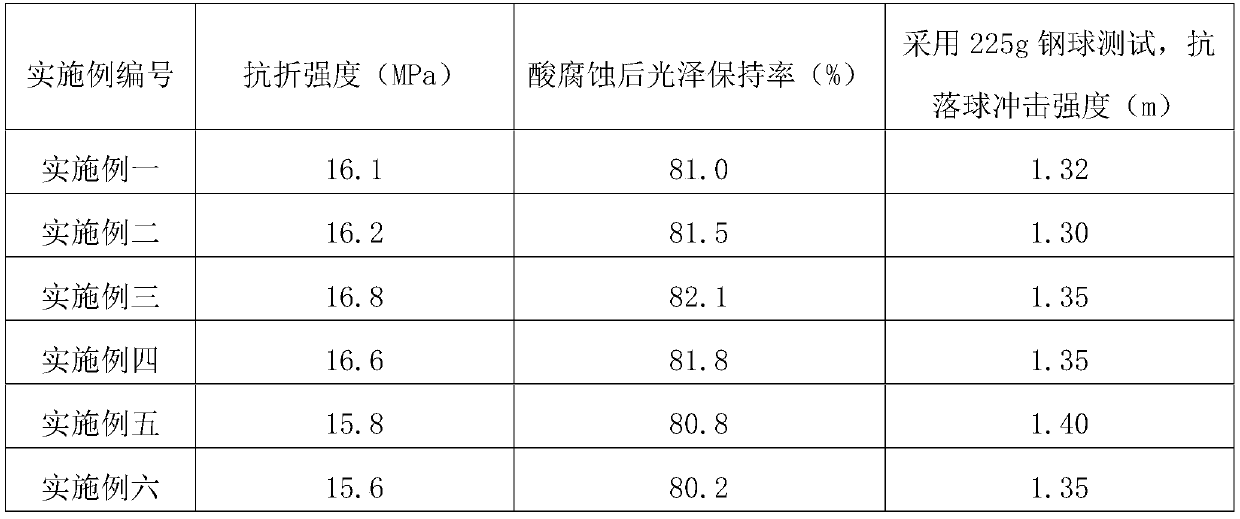

Examples

Embodiment 1

[0030] A geopolymer crack-resistant artificial stone, comprising the following raw material components in parts by weight: 100 parts of ferronickel slag, 35 parts of geopolymer, 7 parts of water, 0.35 parts of water reducing agent, 0.07 parts of plasticizer, and anti-cracking agent 0.7 parts, 0.01 parts of yellow pigment; wherein, the water reducing agent is selected from naphthalene-based water reducing agents; the particle size of ferronickel slag is 50-100 mesh; the plasticizer is hydroxymethyl cellulose, and the viscosity is 4000-6000Pa between .s.

[0031] The preparation method of the anti-crack artificial stone of geopolymer of the present embodiment, comprises the following steps:

[0032] (1) Stirring and mixing of raw materials: Add ferronickel slag, geopolymer, water, water reducer, plasticizer, anti-cracking agent, and colorant into the mixer according to the raw material components and mix for 10 minutes to obtain mixture A;

[0033] (2) extrusion molding: the mi...

Embodiment 2

[0037] A geopolymer anti-crack artificial stone, comprising the following raw material components in parts by weight: 100 parts of ferronickel slag, 35 parts of geopolymer, 7 parts of water, 0.7 part of water reducing agent, 0.07 part of plasticizer, anti-cracking agent 0.8 parts, 0.35 parts of yellow pigment; wherein, the water reducing agent is selected from lignosulfonate series water reducing agents; the particle size of ferronickel slag is 50-100 mesh; the plasticizer is hydroxymethyl cellulose, the viscosity Between 4000-6000Pa.s.

[0038] The preparation method of the anti-crack artificial stone of geopolymer of the present embodiment, comprises the following steps:

[0039] (1) Stirring and mixing of raw materials: Add ferronickel slag, geopolymer, water, water reducer, plasticizer, anti-cracking agent, and colorant into the mixer according to the raw material components and mix for 15 minutes to obtain mixture A;

[0040] (2) extrusion molding: the mixture A obtained...

Embodiment 3

[0044]A geopolymer anti-crack artificial stone, comprising the following raw material components in parts by weight: 100 parts of ferronickel slag, 38 parts of geopolymer, 8 parts of water, 0.82 parts of water reducing agent, 0.085 parts of plasticizer, and anti-cracking agent 0.9 parts, 0.38 parts of red pigment; wherein, the water reducer is selected from sulfamate-based water reducers; the particle size of ferronickel slag is 50-100 mesh; the plasticizer is hydroxymethyl cellulose, and the viscosity is between Between 4000-6000Pa.s.

[0045] The preparation method of the anti-crack artificial stone of geopolymer of the present embodiment, comprises the following steps:

[0046] (1) Stirring and mixing of raw materials: Add ferronickel slag, geopolymer, water, water reducer, plasticizer, anti-cracking agent, and colorant into the mixer according to the raw material components and mix for 15 minutes to obtain mixture A;

[0047] (2) extrusion molding: the mixture A obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com