Macrostructure hot acid etching device

A low-magnification, thermal acid etching technology, applied in the field of metal processing, can solve the problems of monitoring measures, leakage, and high equipment costs, achieve safe and reliable heating, solve safety hazards, and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

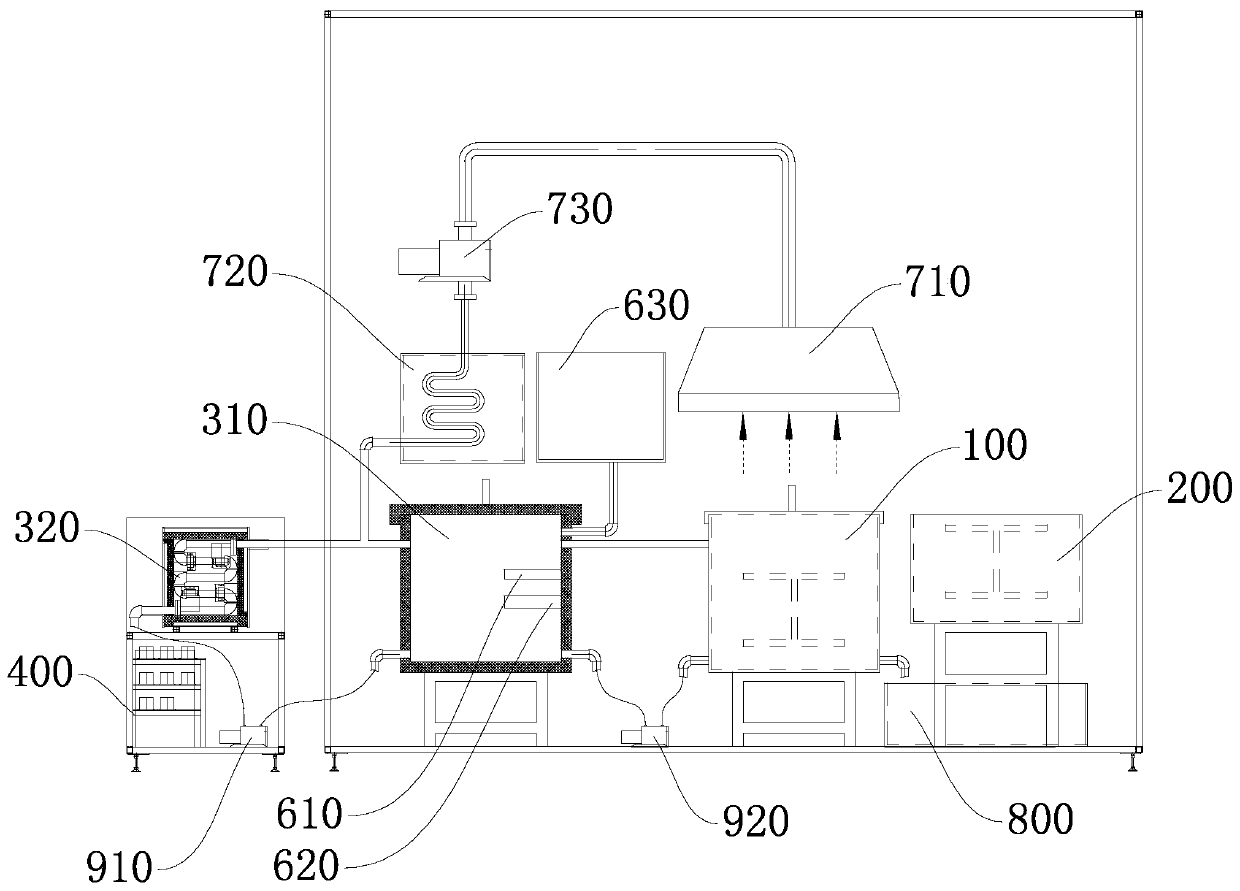

[0022] like figure 1 The low-magnification thermal acid etching device of the illustrated embodiment includes an acid etching tank 100, a workpiece cleaning pool 200, an acid etching solution supply device, and a microwave heating device 400 for heating the etching solution in the acid etching solution supply device. The etching solution supply device communicates with the acid etching tank 100 .

[0023] The microwave field generated by the microwave heating device 400 penetrates the container wall of the acid etching solution supply device and directly acts on the acid etching solution. Contact with the etching solution, so as to achieve the purpose of heating the etching solution safely and reliably.

[0024] After the acid etching solution in the acid etching solution supply device is heated to 60-80 °C, it flows into the acid etching tank 100, and the workpiece to be acid-etched is put into the acid etching tank 100, and is taken out after a certain period of acid etchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com