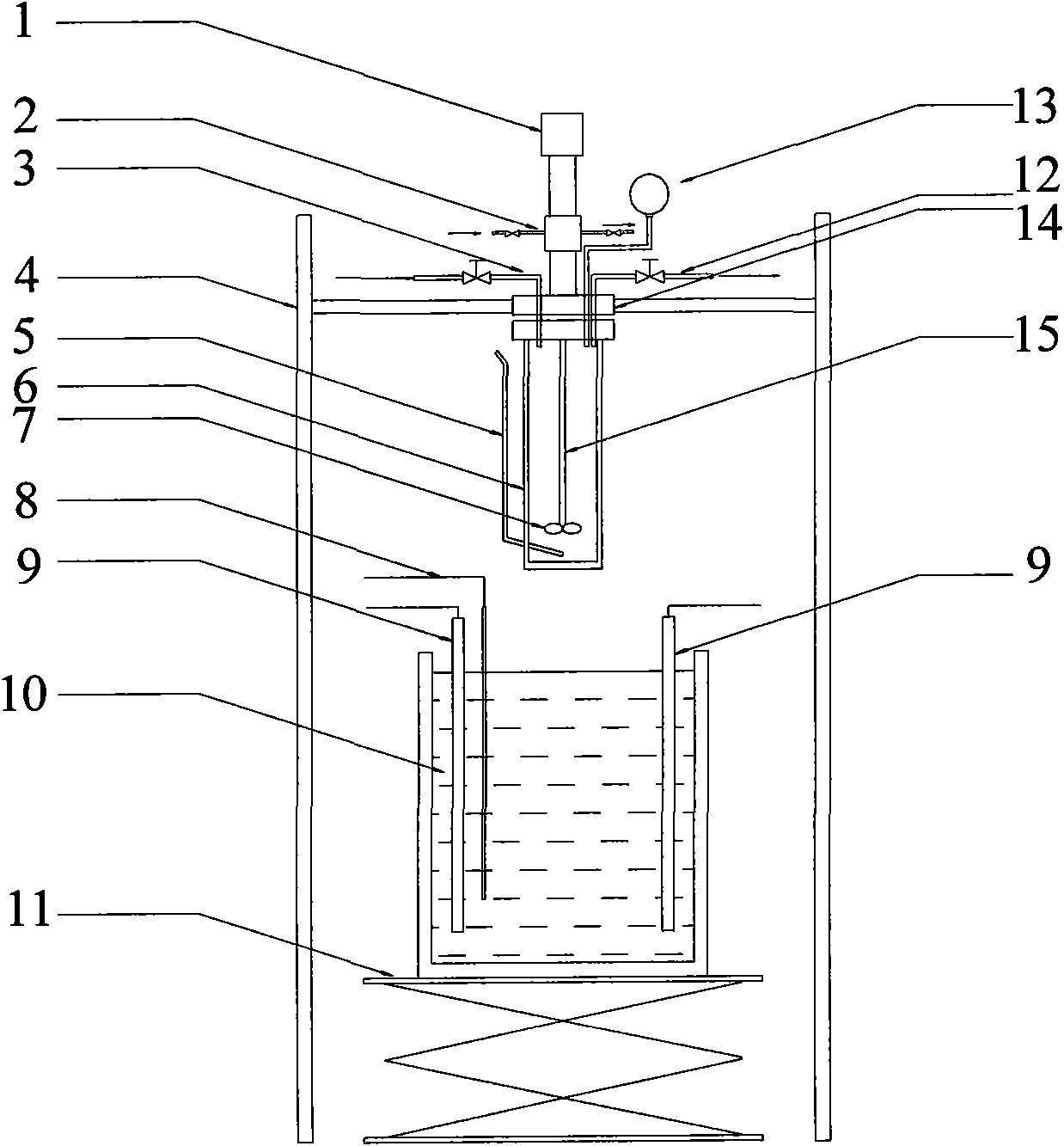

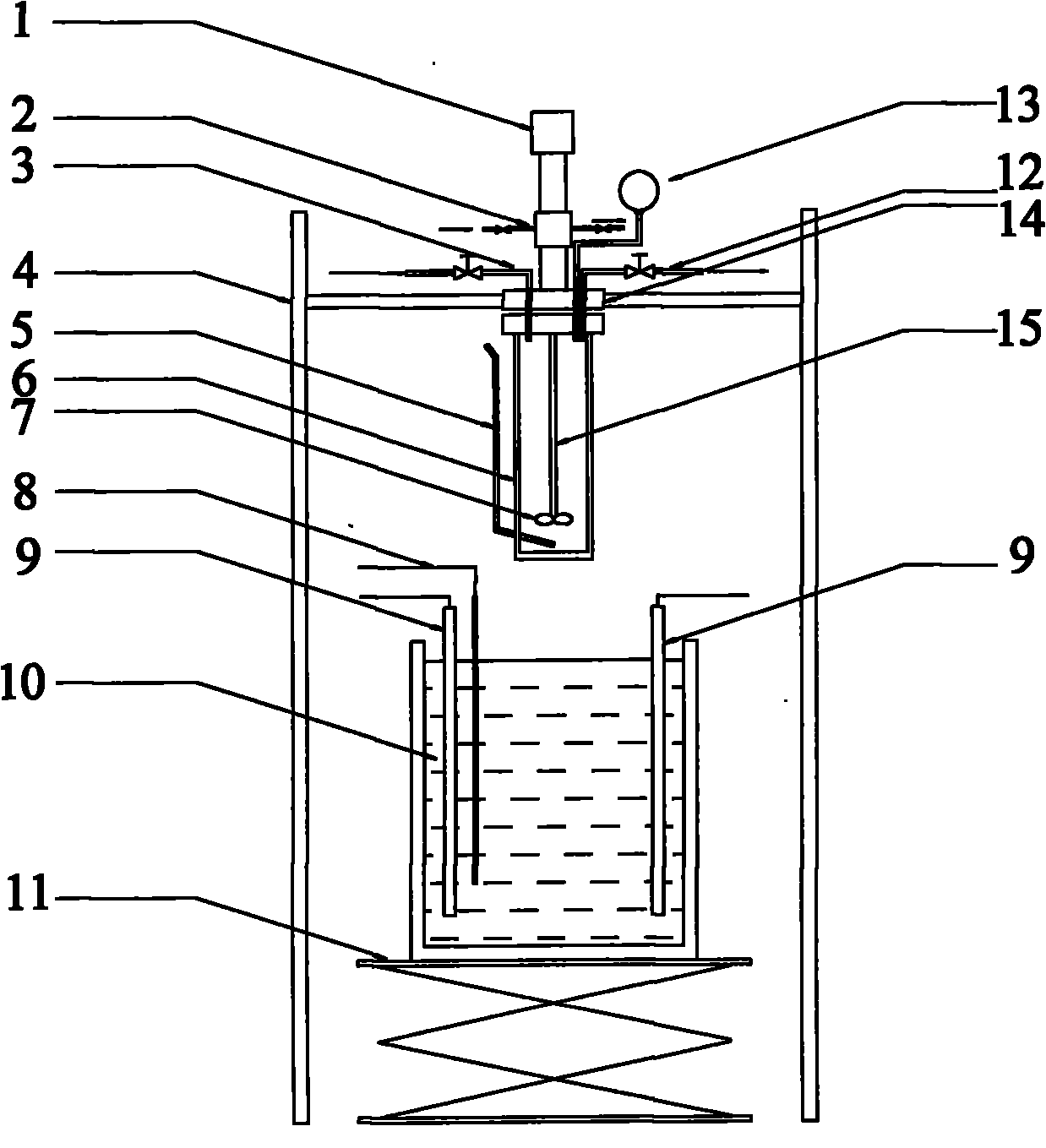

Miniature high-pressure reactor experiment device for direct coal liquefaction and experiment method thereof

A high-pressure reactor and coal direct liquefaction technology, which is applied in the preparation of liquid hydrocarbon mixtures, petroleum industry and other directions, can solve the problems of single function and low quality of high-pressure reactor, and achieve high accuracy, simple operation, safe and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0058] The proportion of oil-coal slurry is 4.0g of coal powder, 6.0g of solvent, and 0.15g of catalyst. The target setting temperature is 450°C, and the reaction residence time is 40min. The rest of the steps are the same as in Example 1.

Embodiment 3

[0060] The proportion of oil-coal slurry is 5.0g of coal powder, 6.0g of solvent, and 0.15g of catalyst. The target setting temperature is 455°C, and the reaction residence time is 60min. The rest of the steps are the same as in Example 1.

[0061] In the specific implementation, open the miniature high-pressure reactor, according to the technical requirements of direct coal liquefaction, fill an appropriate amount of raw materials, tighten the high-pressure flange, and seal the high-pressure reactor to ensure that there is no gas leakage under the reaction pressure; use low-pressure nitrogen, hydrogen Purge the reaction system, then fill the reactor with gas at normal temperature to a certain pressure; open the high-pressure reactor to stir; raise the salt bath furnace to the set temperature in advance, quickly raise the elevator, and raise the salt bath furnace so that the salt The bath submerges the entire autoclave, so that the autoclave rises to a certain temperature, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com