Conduit-type high-frequency electric heater unit, heating device, and heating method

A heating device and heating equipment technology, applied in lighting and heating equipment, induction heating, steam generation methods, etc., can solve the problems of high frequency electromagnetic wire laying requirements, low heating efficiency, small application range, etc., to achieve improved high frequency Heating mode, high work efficiency, reasonable wiring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

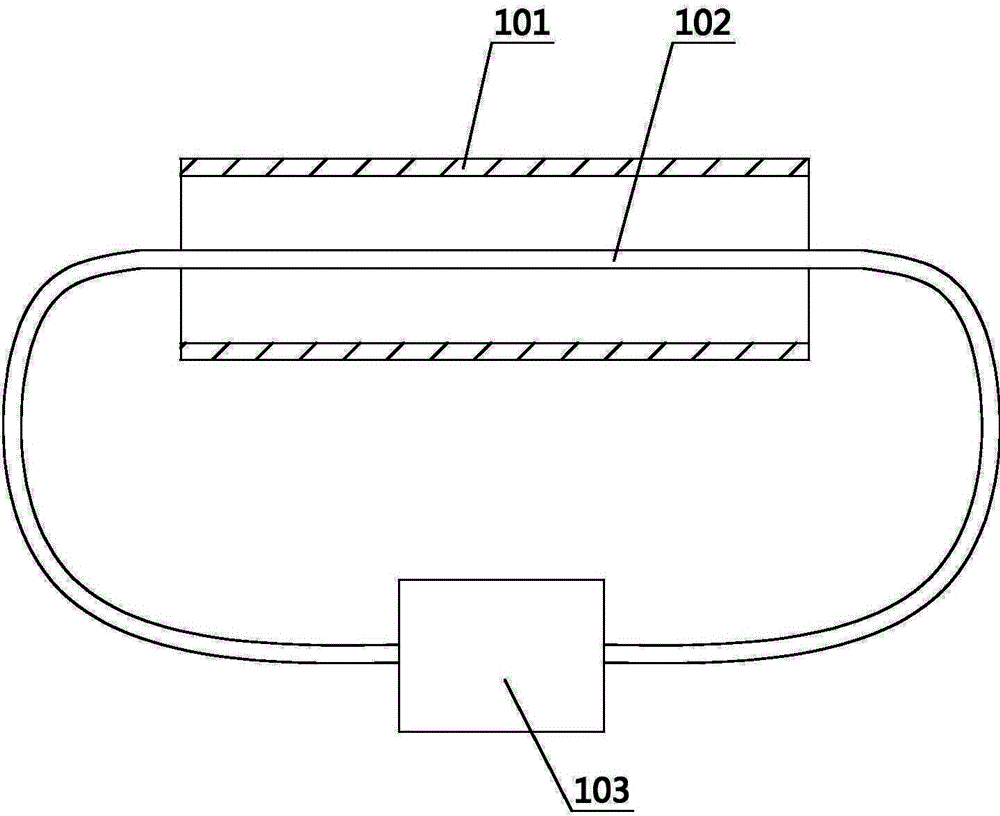

[0062] see figure 1 , this embodiment provides a threading tube type high-frequency electric heating device, the threading tube type high-frequency electric heating device includes at least one heating tube 101, and the heating tube 101 is made of a magnetically conductive metal material. In this embodiment, the heating tube 101 is preferably a magnetically conductive metal seamless carbon steel pipe. At least one high-frequency electromagnetic wire 102 is threaded inside the heating tube 101 , and the high-frequency electromagnetic wire 102 is connected to a high-frequency power supply 103 .

[0063] The high-frequency electromagnetic wire 102 is the prior art, generally multi-strand copper wire, and an insulating material is provided on the copper wire jacket. As a preference, in this embodiment, the high-frequency electromagnetic wire 102 is provided with a high-temperature-resistant protective layer. The high-temperature-resistant protective layer is made of mica glass fi...

no. 2 example

[0069] This embodiment provides a threading tube type high-frequency electric heating device. The basic structure, principle and technical effect of the threading tube type high-frequency electric heating device provided in this embodiment are the same as those of the first embodiment. For the description, for parts not mentioned in this embodiment, reference may be made to the corresponding content in the first embodiment.

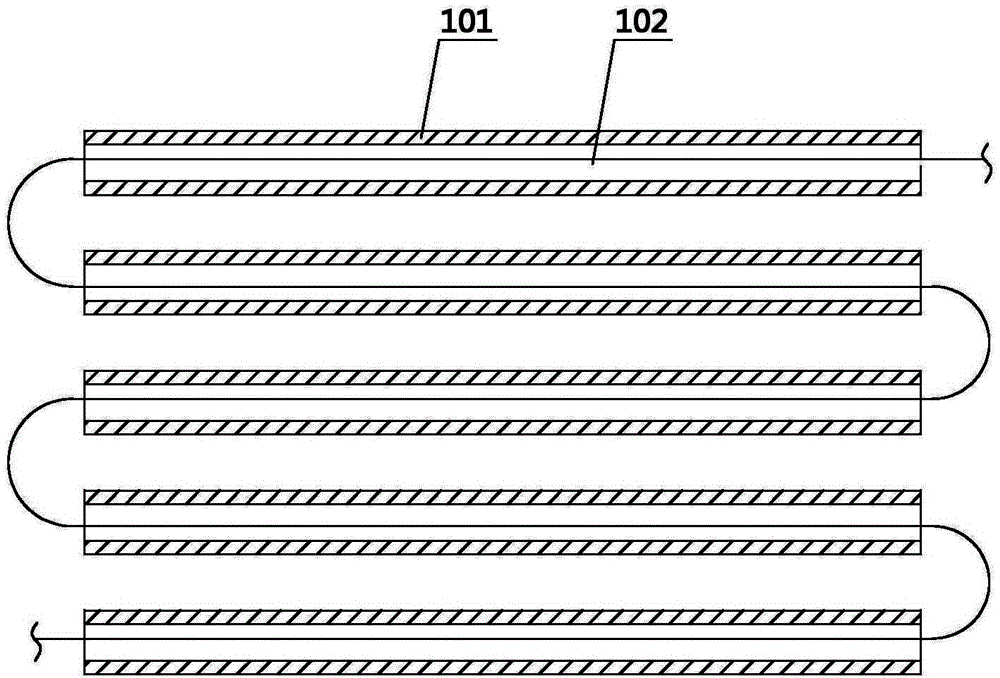

[0070] see figure 2 , there are a plurality of heating pipes 101 arranged side by side, they may be arranged side by side at intervals, or they may be arranged side by side next to each other, and in this embodiment they are arranged at intervals. The high-frequency electromagnetic wires 102 are sequentially passed through the plurality of heating tubes 101 and form an S shape.

[0071] Using multiple heating tubes 101, when the high-frequency electromagnetic wire 102 is connected to the high-frequency power supply 103, multiple heating tubes 101 can be...

no. 3 example

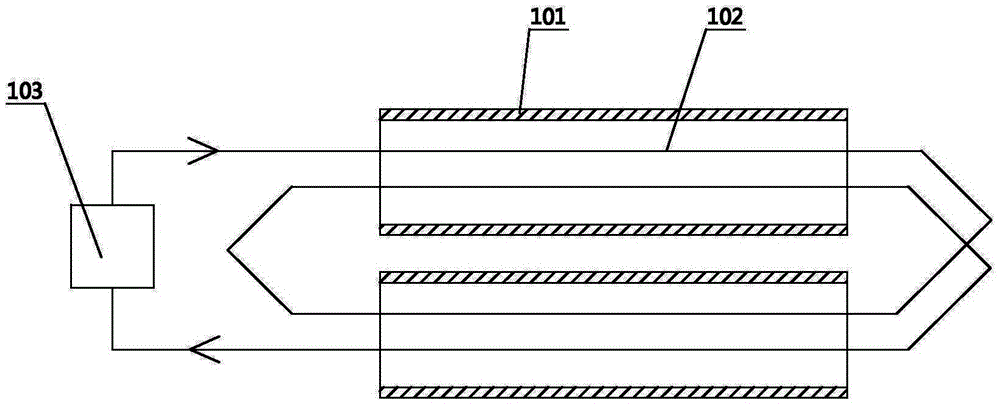

[0073] The only difference between the threaded tube type high-frequency electric heating device provided in this embodiment and the threaded tube type high-frequency electric heating device provided in the first embodiment is:

[0074] see image 3 The high-frequency electromagnetic wire 102 passes around the heating tube 101 to form at least two turns, and each turn passes through the heating tube 101 in the same direction, and the two ends of the high-frequency electromagnetic wire 102 are respectively connected to the high-frequency power supply 103 . In this embodiment, there are two heating tubes 101, and a high-frequency electromagnetic wire 102 is threaded inside the heating tube 101, and the high-frequency electromagnetic wire 102 has two turns. The high-frequency electromagnetic wire 102 enters the heating tube 101 and passes through the opening of the heating tube 101 at the same end of the heating tube 101, so that the high-frequency electromagnetic wire 102 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com