Aluminizing method of alloy base material

An alloy-based, aluminized technology, applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of incomplete aluminizing on the inner wall of the pipe, inability to aluminize the workpiece micro-area, and easy deformation of the workpiece. To achieve the effect of easy operation, smooth surface and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

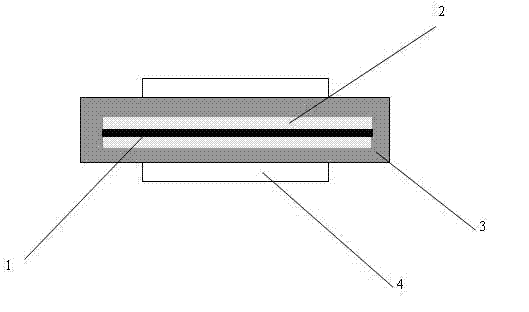

[0013] Specific Embodiment 1: The method of aluminizing the alloy substrate in this embodiment is realized according to the following steps: 1. Use 800# sandpaper to pre-grind the surface of the alloy substrate, then place it in an acetone solution for ultrasonic cleaning for 2 to 6 minutes, and then add 0.1 to 0.5 g / cm 2 AlCl 3 powder or NH 4 Cl powder is coated on the surface of the alloy substrate to obtain a test piece; 2. Wrap the test piece with aluminum foil, and apply a pressure of 0-1 MPa, and then place it in a sintering furnace, in argon atmosphere, hydrogen atmosphere or vacuum 1. The aluminizing treatment is completed at a temperature of 500-1000° C. for 5 minutes to 24 hours; the thickness of the aluminum foil in step 2 is 10-200 μm; the aluminum foil coated in step 2 is 1-5 layers.

[0014] In step 1 of this embodiment, the alloy base material is Ni-based material, Fe-based material, Co-based material, Nb-based material, Ti-based material; the material is a th...

specific Embodiment approach 2

[0018] Embodiment 2: This embodiment differs from Embodiment 1 in that step 1 is ultrasonic cleaning for 3 to 5 minutes. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0019] Embodiment 3: This embodiment differs from Embodiment 2 in that the thickness of the aluminum foil 3 in step 2 is 20-180 μm. Other steps and parameters are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com