Dioctyl phthalate recycling equipment

A technology for recycling equipment and dioctyl ester, applied in the field of purification equipment, can solve the problems of short circuit of positive and negative electrodes, inconvenient cleaning, affecting recycling efficiency, etc., to prevent short circuit of positive and negative electrodes, facilitate installation and transportation, and ensure recycling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

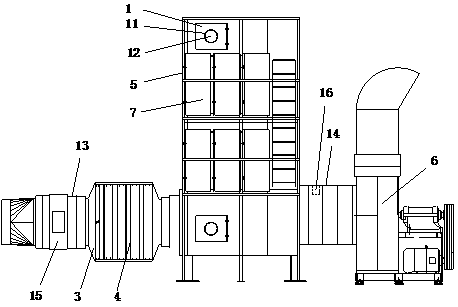

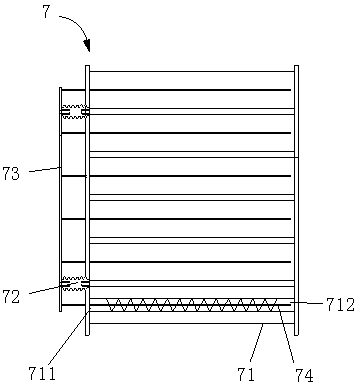

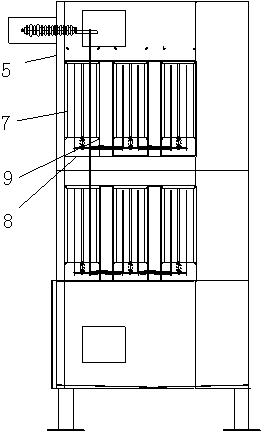

[0044] refer to figure 1 , figure 2 As shown, a kind of dioctyl ester recovery equipment, it comprises high-voltage power supply, controller 2 and filter 3, cooler 4, electrostatic recovery device 5, blower fan 6 connected in sequence, and electrostatic recovery device 5 is provided with a plurality of interconnected Each high-voltage electrostatic generator 7 includes m anode cylinders 71, n insulators 72, and electric field frames 73, m and n are natural numbers, m>n, and m anode cylinders 71 are arranged parallel to each other On the electric field frame 73, each anode cylinder 71 is provided with a cathode needle 74, one end of each anode c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com