Basalt fiber composite cable

A technology of basalt fiber and composite bars is applied in the cable field to achieve the effects of eliminating potential safety hazards, enhancing anti-fatigue ability and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

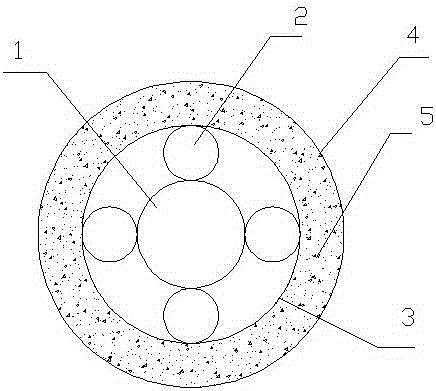

[0019] Such as figure 1 As shown, this embodiment includes a central compound bar 1, a peripheral compound bar 2, an inner sheath 3, a filler 5 and an outer sheath 4, the central compound bar 1 is located at the center, and the peripheral compound bar 2 is wound on the central compound bar 1 , the central composite rib 1 and the peripheral composite rib 2 are wrapped in the inner sheath 3, the filler 5 is filled between the outer sheath 4 and the inner sheath 3, the filler 5 is an elastic filler, and the central composite rib 1 is made of continuous The basalt fiber and glass fiber are composited through a resin matrix, and the peripheral composite ribs 2 are composited by carbon fiber and aramid fiber through a resin matrix. The filler 5 is butadiene rubber, and the inner sheath 3 and the outer sheath 4 are both polyethylene sheaths.

Embodiment 2

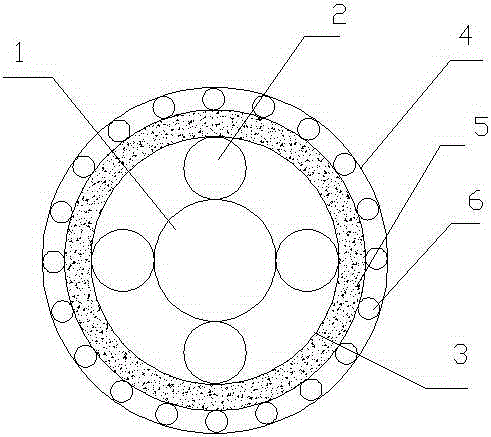

[0021] Such as figure 2 As shown, this embodiment includes a central compound bar 1, a peripheral compound bar 2, an inner sheath 3, a filler 5 and an outer sheath 4, the central compound bar 1 is located at the center, and the peripheral compound bar 2 is wound on the central compound bar 1 , the central composite rib 1 and the peripheral composite rib 2 are wrapped in the inner sheath 3, the filler 5 is filled between the outer sheath 4 and the inner sheath 3, the filler 5 is an elastic filler, and the central composite rib 1 is made of continuous The basalt fiber and glass fiber are composited through a resin matrix, and the peripheral composite ribs 2 are composited by carbon fiber and aramid fiber through a resin matrix. The filler 5 is butadiene rubber, and the inner sheath 3 and the outer sheath 4 are both polyethylene sheaths. A reinforcing rib 6 is also arranged between the inner sheath 3 and the outer sheath 4, and the reinforcing rib 6 is made of continuous basalt...

Embodiment 3

[0023] This embodiment includes a central compound bar 1, a peripheral compound bar 2, an inner sheath 3, a filler 5 and an outer sheath 4, the central compound bar 1 is located at the center, the peripheral compound bar 2 is wound on the central compound bar 1, and the center compound bar The rib 1 and the surrounding composite rib 2 are wrapped in the inner sheath 3, the filler 5 is filled between the outer sheath 4 and the inner sheath 3, the filler 5 is an elastic filler, and the central composite rib 1 is made of continuous basalt fiber and The glass fiber is compounded through a resin matrix, and the peripheral composite rib 2 is formed by compounding carbon fibers and aramid fibers through a resin matrix. The filler 5 is butadiene rubber, and the inner sheath 3 and the outer sheath 4 are both polyethylene sheaths. A reinforcing rib 6 is also arranged between the inner sheath 3 and the outer sheath 4, and the reinforcing rib 6 is made of continuous basalt fiber.

[0024...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com