Manufacture method for stone pattern color-coating aluminum plate

A manufacturing method and aluminum plate technology, applied in the field of aluminum plate manufacturing, can solve problems such as poor weather resistance, blurred texture, false graphics, etc., and achieve the effects of not easy to fall off, good adhesion, and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

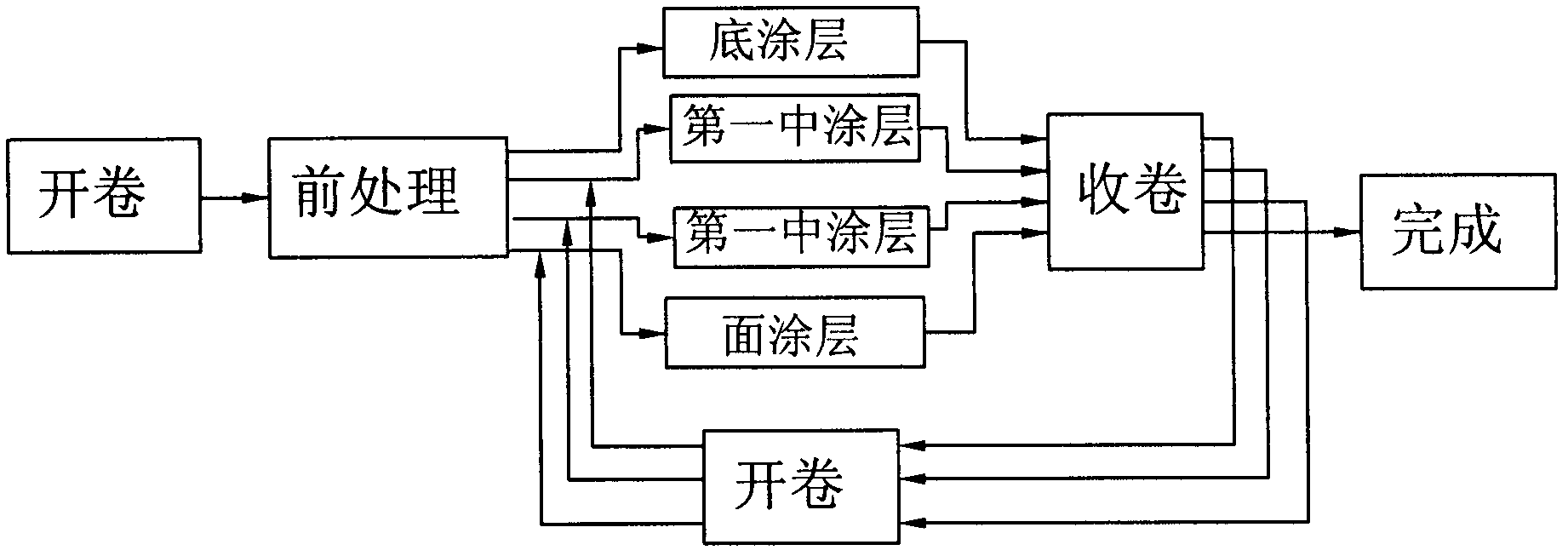

[0028] A method for manufacturing a stone pattern color-coated aluminum plate, the process of the method is:

[0029] a. Carry out pretreatment processing on the aluminum plate. The pretreatment processing of the aluminum plate includes cleaning with alkaline water and acid water to realize degreasing processing, and adopting surface chromization processing to form a passivation film layer to realize passivation processing. After the pretreatment processing The aluminum plate is uncoiled;

[0030] b. Coating a primer on the surface of the pretreated aluminum plate, the primer is polyurethane paint, baked in an oven to form a primer, and then rewinding the aluminum plate with the primer , wherein the oven is divided into four zones, and the aluminum plate coated with primer is baked sequentially, the temperature of the first zone is 240°C, the temperature of the second zone is 260°C, and the temperature of the third zone is 280°C , the temperature in the fourth zone is 260°C; ...

Embodiment 2

[0040] A method for manufacturing a stone pattern color-coated aluminum plate, the process of the method is:

[0041] a. Carry out pretreatment processing on the aluminum plate. The pretreatment processing of the aluminum plate includes cleaning with alkaline water and acid water to realize degreasing processing, and adopting surface chromization processing to form a passivation film layer to realize passivation processing. After the pretreatment processing The aluminum plate is uncoiled;

[0042] b. Coating a primer on the surface of the pretreated aluminum plate, the primer is polyurethane paint, baked in an oven to form a primer, and then rewinding the aluminum plate with the primer , wherein the oven is divided into four zones, and the aluminum plate coated with primer is baked sequentially, the temperature of the first zone is 260°C, the temperature of the second zone is 280°C, and the temperature of the third zone is 310°C , the temperature in the fourth zone is 260°C; ...

Embodiment 3

[0052] A method for manufacturing a stone pattern color-coated aluminum plate, the process of the method is:

[0053] a. Carry out pretreatment processing on the aluminum plate. The pretreatment processing of the aluminum plate includes cleaning with alkaline water and acid water to realize degreasing processing, and adopting surface chromization processing to form a passivation film layer to realize passivation processing. After the pretreatment processing The aluminum plate is uncoiled;

[0054] b. Coating a primer on the surface of the pretreated aluminum plate, the primer is polyurethane paint, baked in an oven to form a primer, and then rewinding the aluminum plate with the primer , wherein the oven is divided into four zones, and the aluminum plate coated with primer is baked sequentially, the temperature of the first zone is 250°C, the temperature of the second zone is 270°C, and the temperature of the third zone is 295°C , the temperature in the fourth zone is 270°C; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com