Novel insulating flange

A flange, a new type of technology, applied in the direction of flange connections, pipes/pipe joints/fittings, passing components, etc., can solve the problems of high processing precision requirements, troublesome installation and processing, and large space occupation of sealing waterlines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

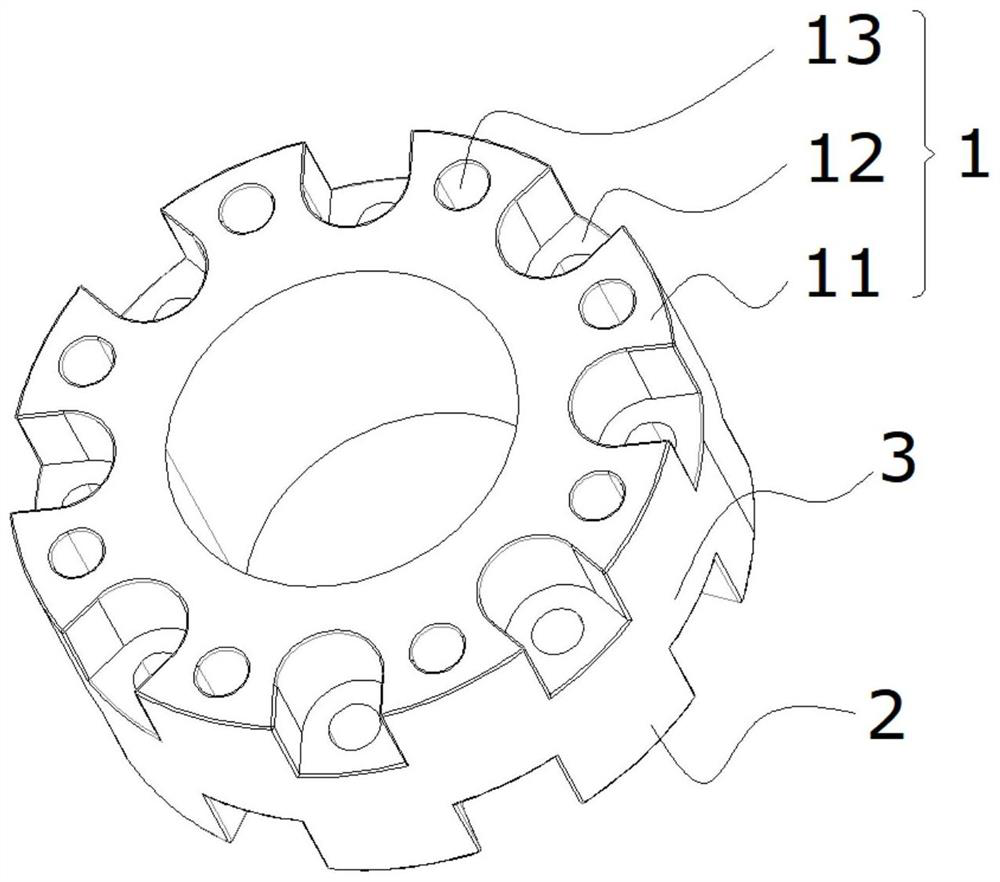

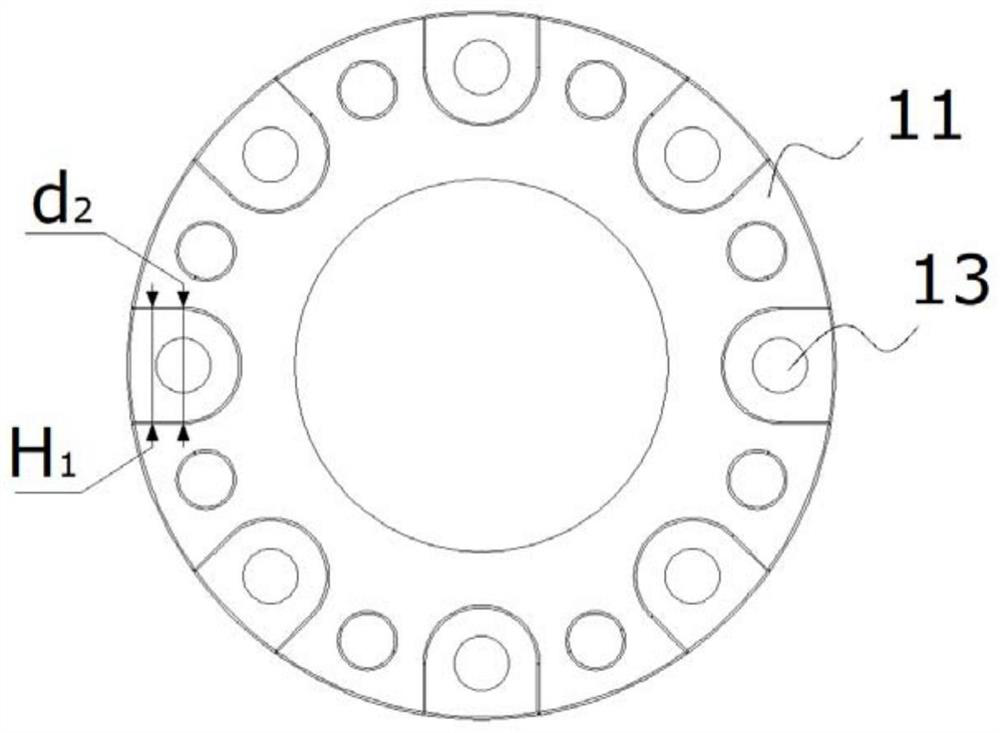

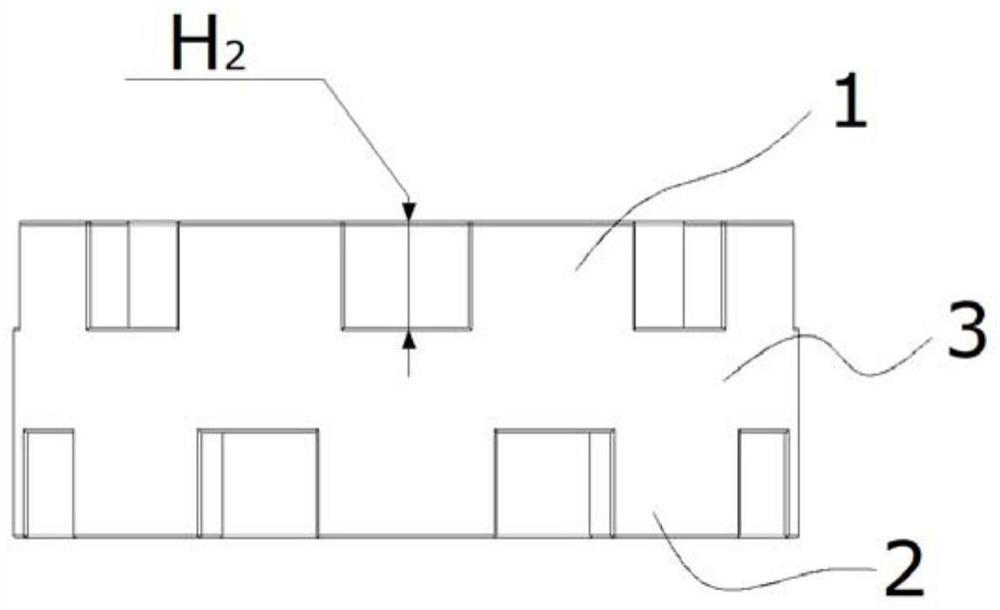

[0040] A new type of insulating flange, which is detachably arranged on the joint of the pipeline, is characterized in that it includes an integrally formed flange, and the flange includes an upper flange 1, a lower flange 2 and a The connecting portion 3 between the upper flange 1 and the lower flange 2; wherein, the upper flange 1 includes a plurality of installation parts 11 and slots 12 arranged at intervals, on the installation part 11 A threaded through hole 13 that runs through the upper flange 1 and the connecting portion 3 is provided; the lower flange 2 has the same structure as the upper flange 1; the upper flange 1 and the The lower flanges 2 are staggered, wherein, the installation part 11 of the upper flange 1 corresponds to the slot 12 of the lower flange 2, and the slot 12 of the upper flange 1 corresponds to the lower flange 1. The mounting part 11 of the flange 2 corresponds.

[0041] By integrally forming the upper flange 1 and the lower flange 2, and inter...

Embodiment 2

[0050] On the basis of Embodiment 1, this embodiment also provides an insulating flange that can be installed without a wrench. As a further improvement, the slot 12 passes through the thread from the flange mounting surface. The hole 13 is machined axially, and the bottom plane of the slot 12 is parallel to the mounting surface of the flange.

[0051] In order to ensure the bolt connection strength, preset nuts or preset threaded sleeves are set in the slot 12. The shape of the slot 12 includes but is not limited to rectangle, circle, regular hexagon or special shape. The shape of the slot 12 Adapt to the preset nut or preset threaded sleeve.

[0052] As a further improvement, if a preset nut is set in the slot 12, the thickness of the preset nut is defined as h 2 , the depth of the groove 12 is H 3 , then there is H 3 = 2h 2 ; If the preset threaded sleeve is embedded in the slot 12, the axial length of the preset threaded sleeve is defined as h 3 , then there is H 3 =...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com