Conveying device based on vacuum suction cups

A technology of vacuum suction cups and conveying devices, which is applied in the direction of conveyor objects, transportation and packaging, etc. It can solve the problems of affecting the material transportation process, affecting the suction cup adsorption force, suction cup adsorption failure, etc., and achieves improved aesthetics, high work efficiency, and reduced The effect of maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

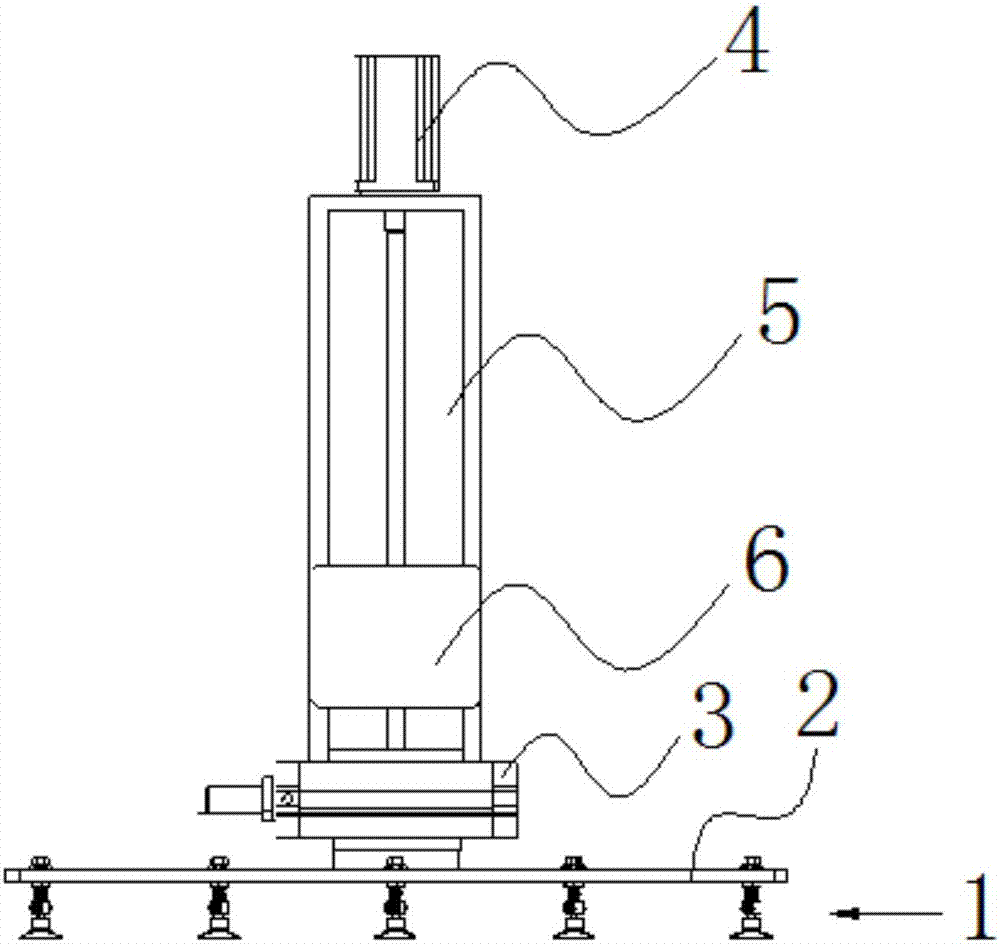

[0028] Embodiment: a kind of conveying device based on vacuum suction cup, as Figure 1-Figure 3 shown, including vacuum cup assembly and delivery assembly;

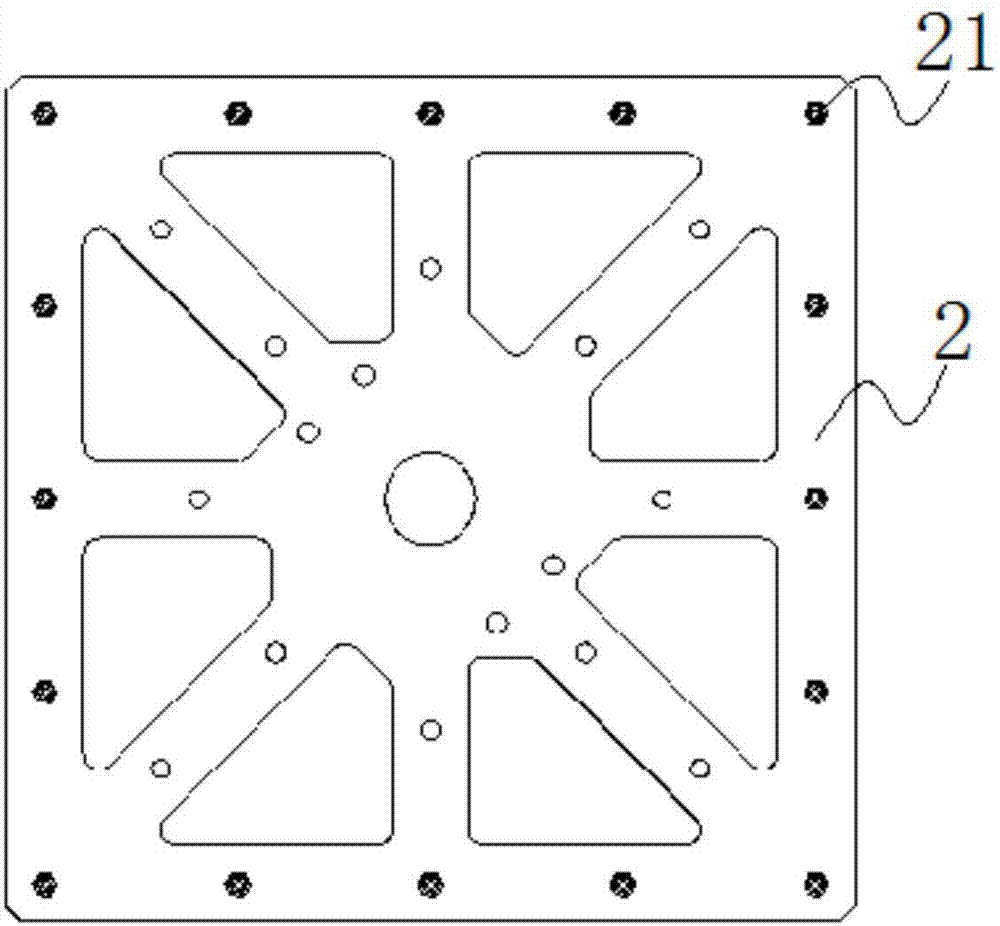

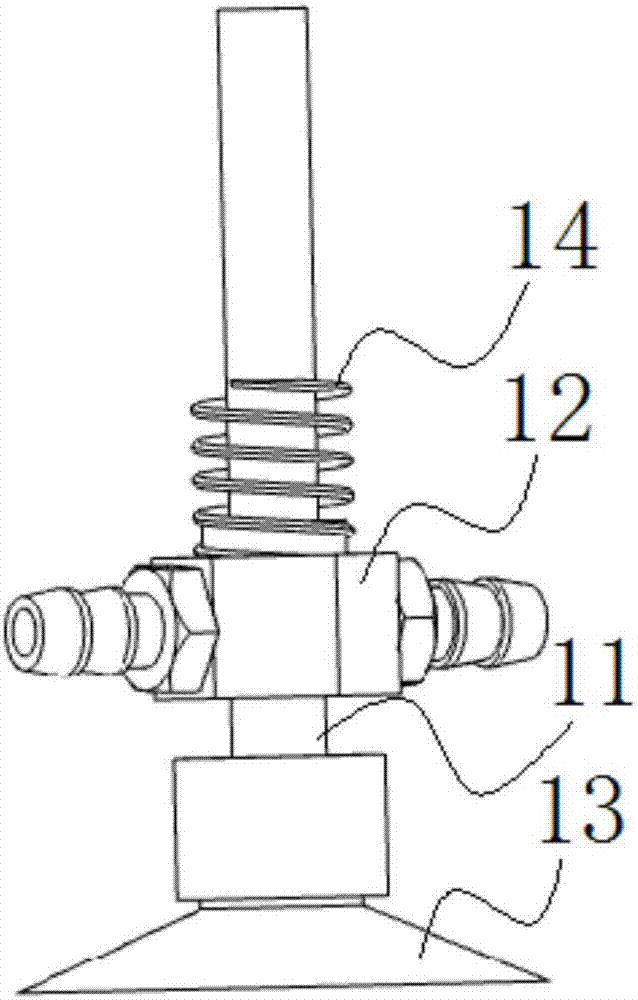

[0029] The vacuum suction cup assembly includes several vacuum suction cup supports 1 and a suction cup holder 2, and several fixing holes 21 are distributed on the suction cup holder 2, and the upper end of the vacuum suction cup support 1 is detachably connected with the fixing holes 21 ;

[0030] The conveying assembly includes a horizontal rotation mechanism and an up and down movement mechanism; the horizontal rotation mechanism includes a rotary cylinder 3 that can drive the suction cup frame 2 to rotate in the horizontal direction; the up and down movement mechanism includes a motor 4, a screw mandrel 5 and a slider 6 that can move up and down along the screw mandrel 5, one end of the screw mandrel 5 is connected to the output shaft of the motor 4 and the other end is connected to the rotary cylinder 3, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com