Pre-manufacturing method and pre-manufactured structure for LED package

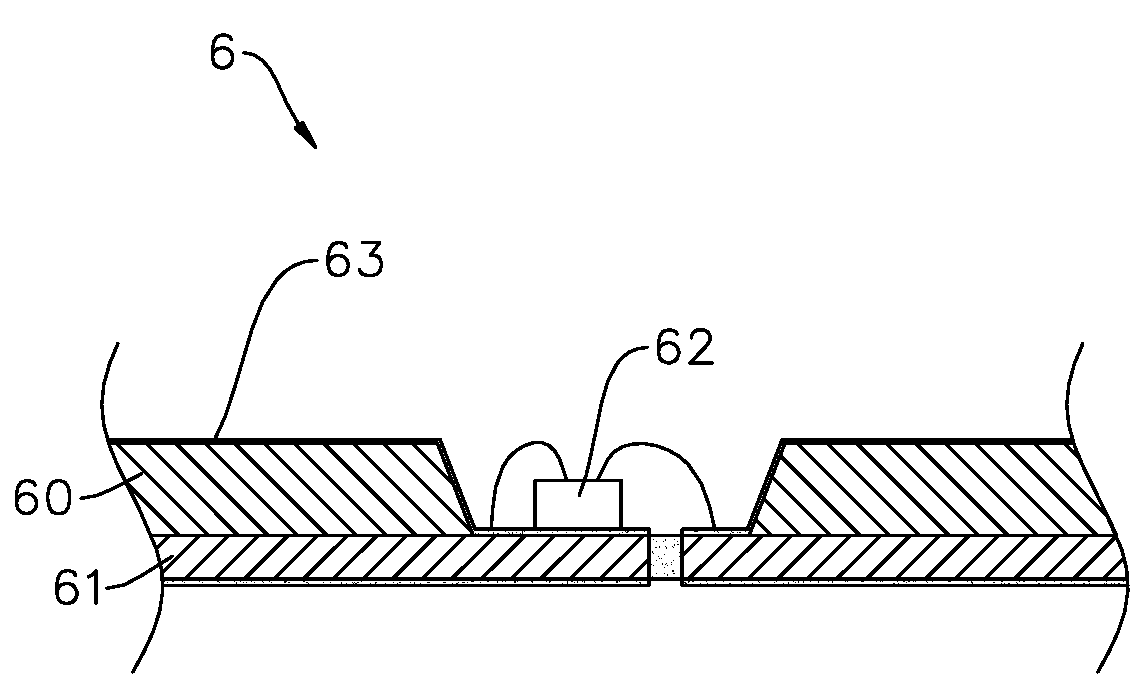

A technology of light-emitting diodes and pre-processing, applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of easy embrittlement of the reflective base 60, damage to the packaging structure of light-emitting diodes, and reduced luminous efficiency, so as to reduce the damage rate , reduce production cost, increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

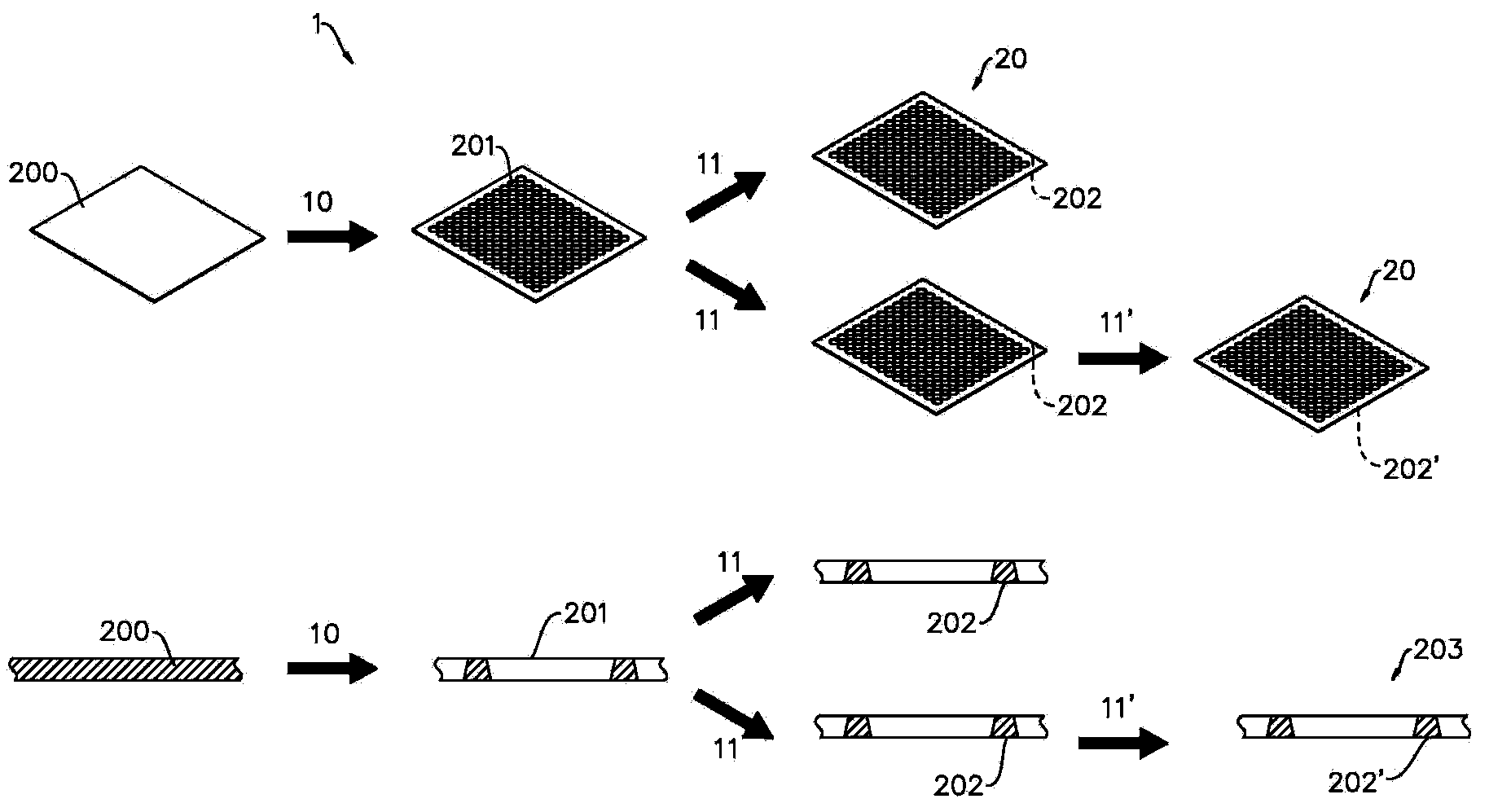

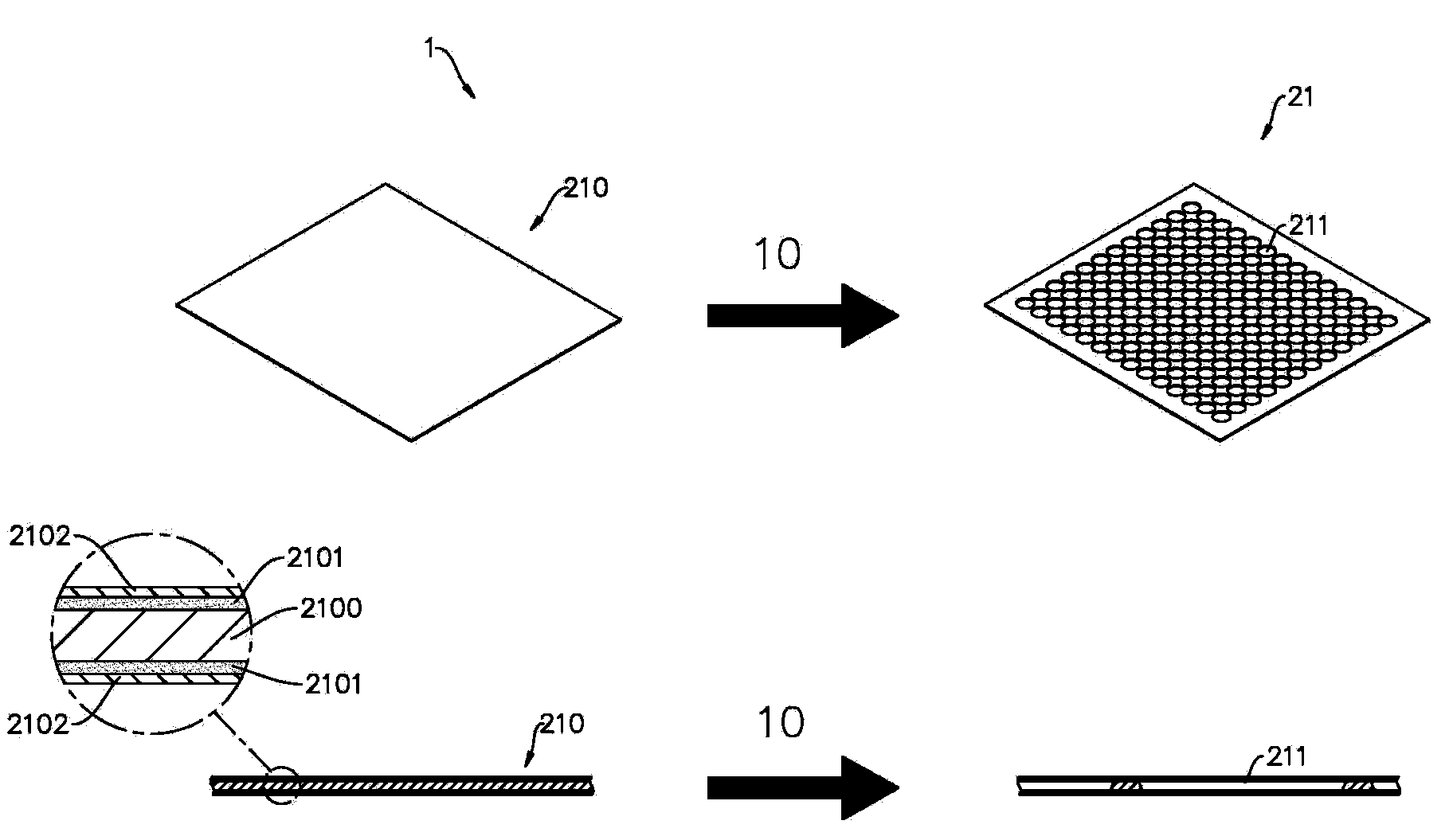

[0066] Such as figure 2 As shown, the reflective cup base material 200 which is copper foil is stamped 10 times to form more than two openings arranged in a rectangular array on the reflective cup base material 200 in the shape of a hollow cylinder or an indented bevel 201. Next, perform mechanical roughening 11 on the bottom surface of the reflective cup base material 200, so that a rough surface 202 is formed on the bottom surface of the reflective cup base material 200 to increase the contact area. Further chemical roughening 11' is carried out on the rough surface 202 (grinding by chemical polishing liquid, blackening and browning process by oxidant, and roughening operation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com