Polyester resin composition, polyester injection-molded article, polyester extrusion-molded article, polyester foam, polyester container, polyester bottle, polyester tableware, and polyester feeding bottle

A technology of polyester resin and composition, applied in the field of polyester resin composition, can solve the problems of poor transparency and high crystallinity, and achieve the effects of excellent retention, excellent impact resistance and not easy to embrittlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0085] Hereinafter, although an Example is given and this embodiment is demonstrated in more detail, this embodiment is not limited to the range of these Examples.

[0086] 〔Evaluation method〕

[0087] The evaluation methods of the polyester resins and polyester resin compositions in this example are as follows.

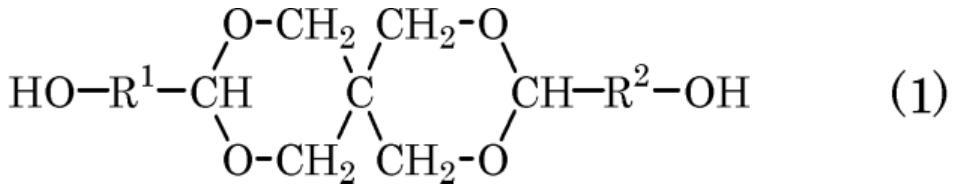

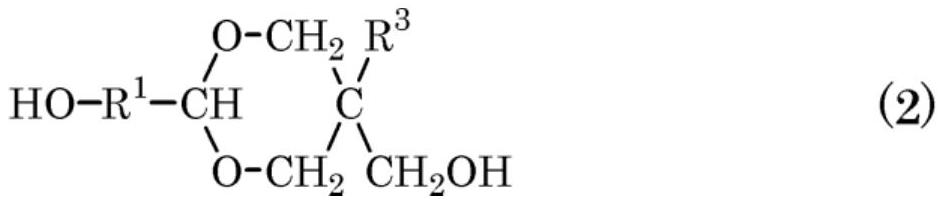

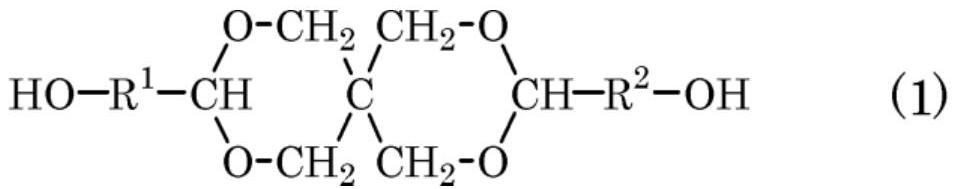

[0088] (1) The ratio of diol units having a cyclic acetal skeleton to alicyclic diol units

[0089] The ratio of the unit derived from the diol having a cyclic acetal skeleton and the unit derived from the alicyclic diol in the polyester resin is determined by 1 H-NMR measurement and calculation. As a measurement device, Ascend TM500 manufactured by Bruker BioSpin K.K. was used for measurement. As the solvent, deuterated chloroform was used.

[0090] (2) Glass transition temperature and crystallization exothermic peak when cooling down

[0091] Glass transition temperature (Tgm) of polyester resin Using a differential scanning calorimeter (model: DSC / TA-50WS) ma...

manufacture example 1~3

[0097] [Synthesis of polyester resins (PEs-1, PEs-2 and PEs-3)]

[0098]For the polyester manufacturing device with a capacity of 30 L equipped with a packed column rectification column, partial condenser, total condenser, cold trap, stirrer, heating device and nitrogen introduction pipe, the raw material monomers recorded in Table 1 are charged, and the dicarboxylic As the acid component, 0.005 mol % of tetra-n-butoxytitanium and 0.02 mol % of potassium acetate were added, and the temperature was raised to 225° C. under a nitrogen atmosphere to carry out a transesterification reaction. After making the reaction conversion rate of the dicarboxylic acid component reach more than 90%, with respect to the dicarboxylic acid component, add germanium dioxide 0.025 mol %, triethyl phosphate 0.05 mol %, slowly carry out heating and depressurization, finally at 280 ℃, 0.1kPa or less for polycondensation. The reaction was terminated when a moderate melt viscosity was reached, and polye...

Embodiment 1

[0110] (production of kneaded pellets)

[0111] Use a twin-screw kneading extruder (manufactured by Toshiba Machinery Co., Ltd., model: TEM26SX, screw diameter: L / D: 48), the polyester resin synthesized in Production Example 1 and polycarbodiimide were dry-blended at a ratio of 99.9 / 0.1% by mass, and then charged from a hopper. Extrude into strands under the conditions of barrel temperature 180-260°C, mold temperature 260°C, screw speed 75rpm, discharge rate 15kg / h, and granulate after water-cooling to obtain polyester resin / polycarbonate Amine compounded pellets.

[0112] (Injection molding of kneaded pellets)

[0113] Next, injection molding of the obtained kneaded pellets is performed. For injection molding, an injection molding machine manufactured by Nippon Steel Works Co., Ltd., model: J85AD was used, and molding was carried out under conditions of a cylinder temperature of 245 to 280°C and a mold temperature of 15 to 50°C. Using the molded test piece, a haze measur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com