Picosecond pulse laser welding machine

A laser welding machine and picosecond pulse technology, applied in the field of picosecond pulse laser welding machine, can solve the problems of easy brittleness of materials, weak welding, long laser pulse heating time, etc., and achieve high connection strength, high pulse peak value, The effect of high welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

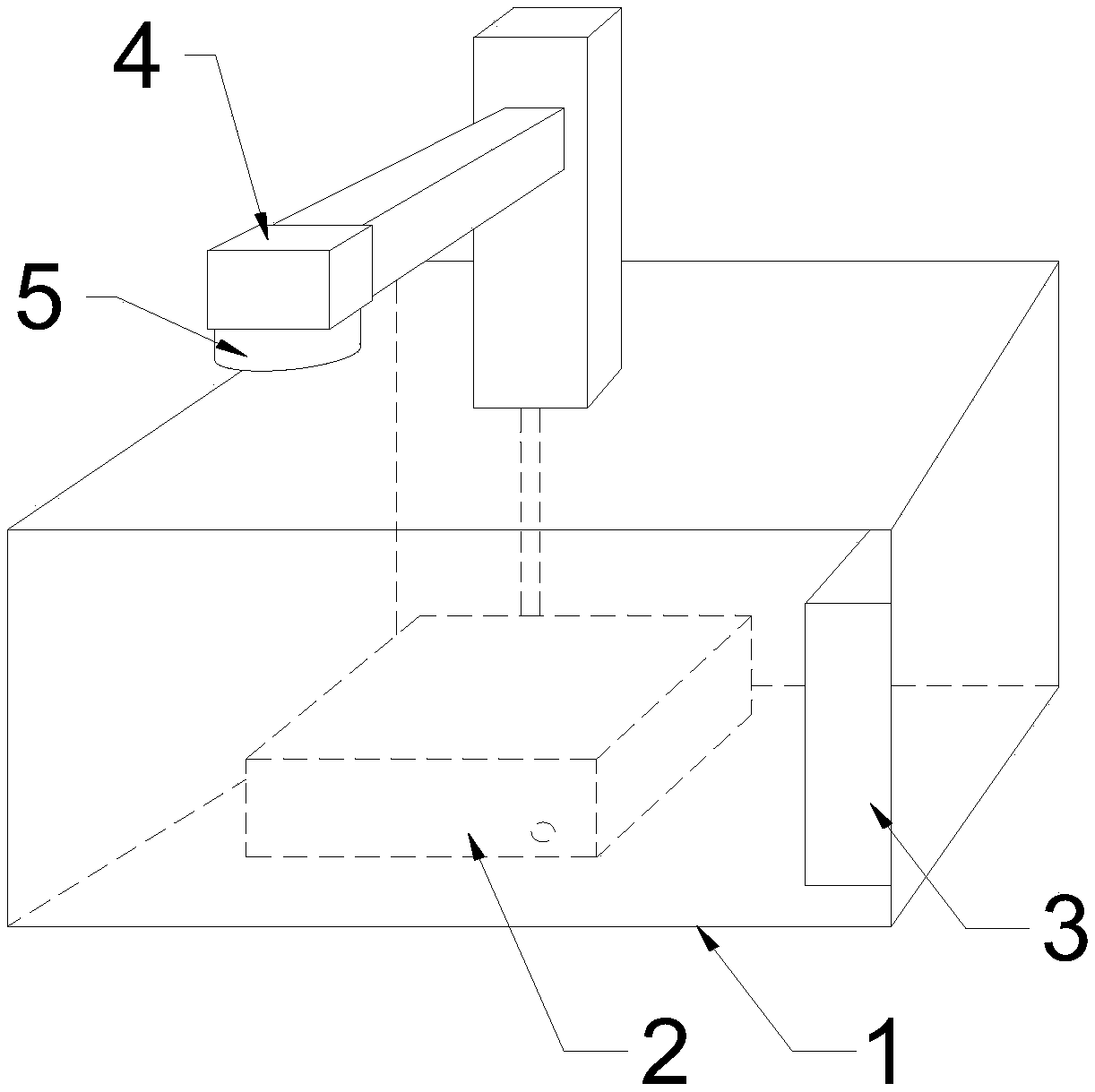

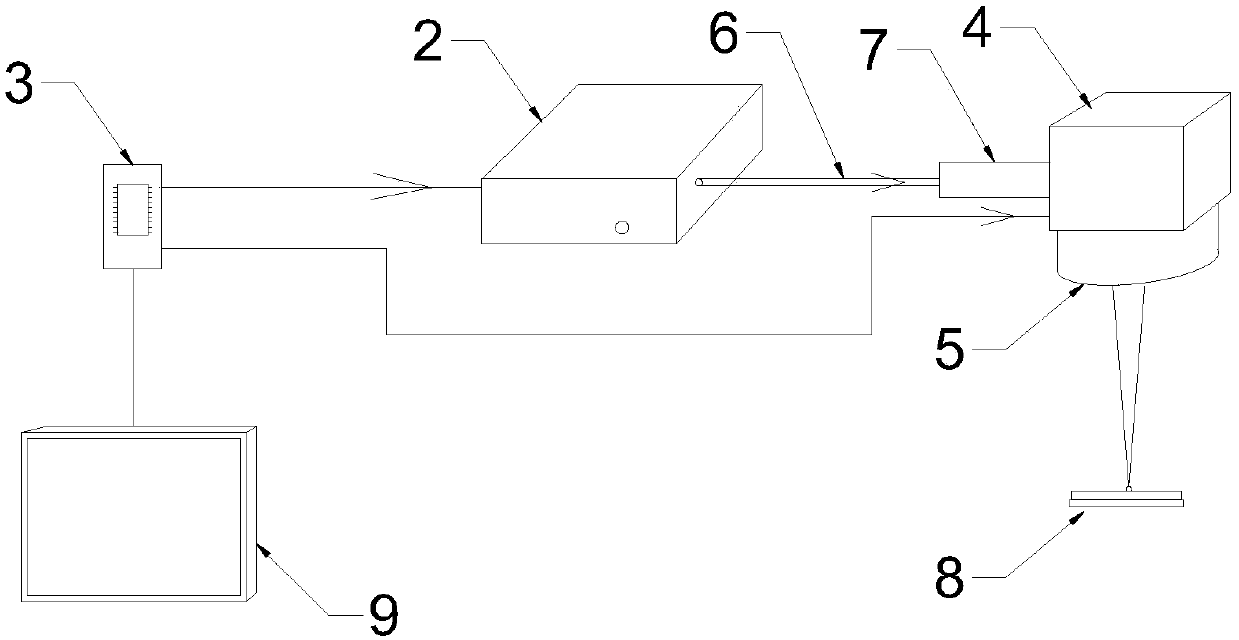

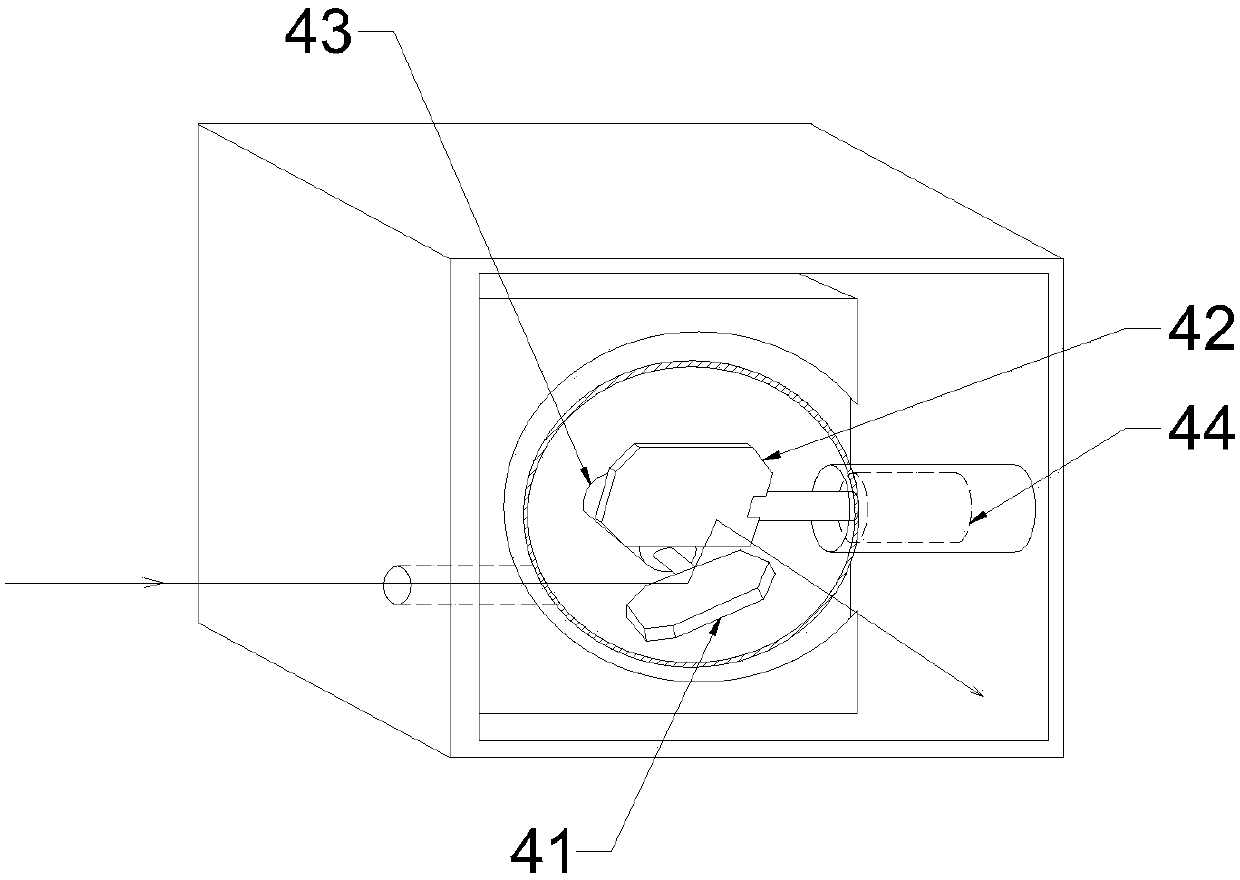

[0021] Such as Figure 1 to Figure 3 As shown, a picosecond pulse laser welding machine includes a chassis 1. A picosecond pulse laser 2 and a control board 3 are arranged in the chassis 1. A vibrating mirror 4 and a field mirror 5 are sequentially installed on the top of the chassis 1 through a bracket. The field mirror 5 is connected to the bottom of the vibrating mirror 4. The picosecond pulse laser 2 is connected to the vibrating mirror 4 through the optical fiber 6. The vibrating mirror 4 includes an X-axis mirror 41 and a Y-axis mirror 42. The X-axis mirror 41 is connected to an X-axis motor 43, and the X-axis motor 43 can drive the X-axis mirror 41 to vibrate and rotate at high speed, and the Y-axis mirror 42 is connected with a Y-axis motor 44, which can drive the Y-axis mirror 42 to vibrate and rotate at a high speed; the laser beam emitted by the picosecond pulse laser 2 passes through the X After the axis lens 41 and the Y axis lens 42 change direction and vibrate a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com