Low-temperature-impact-resistant stress-whitening-resistant polypropylene material and preparation method thereof

A technology for anti-stress whitening and polypropylene materials, applied in the field of polypropylene composite materials, can solve the problems of limited application scope and poor appearance of parts, and achieve the effects of uniform phase structure, tight arrangement and improved crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

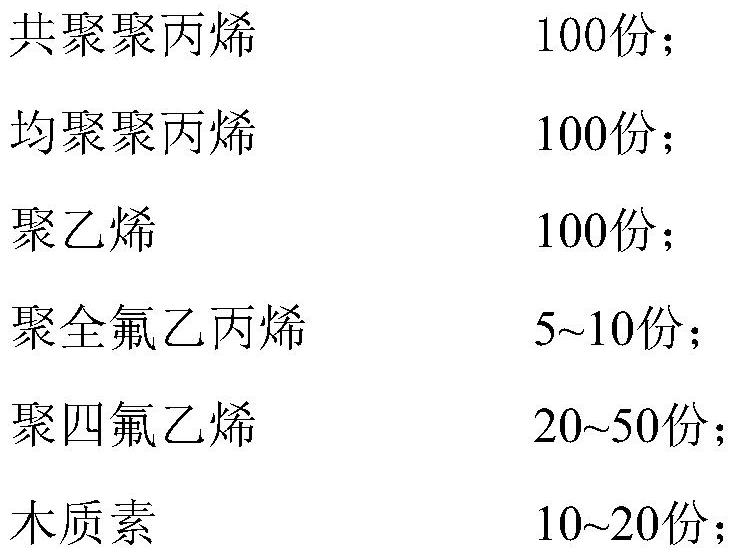

[0035] A preparation method of a low-temperature impact-resistant stress-resistant whitening polypropylene material adopts the following formula:

[0036]

[0037]

[0038] The preparation steps are as follows:

[0039] (1) Mix polyperfluoroethylene propylene and polytetrafluoroethylene in a mixer for 2 minutes according to the formula ratio to obtain mixture A;

[0040] (2) According to the formula ratio, the copolymerized polypropylene, homopolypropylene, polyethylene and lignin were mixed in a mixer for 2 minutes to obtain a mixture B;

[0041] (3) Add mixture A from the first barrel of the twin-screw extruder, feed mixture B from the sixth section of the twin-screw extruder, and carry out extrusion granulation to obtain low-temperature impact-resistant stress-resistant White polypropylene material; wherein, the speed of the twin-screw extruder is 500r / min, and the temperatures of the first to sixth barrels are 280°C, 285°C, 288°C, 290°C, 300°C, 310°C, respectively. ...

Embodiment 2

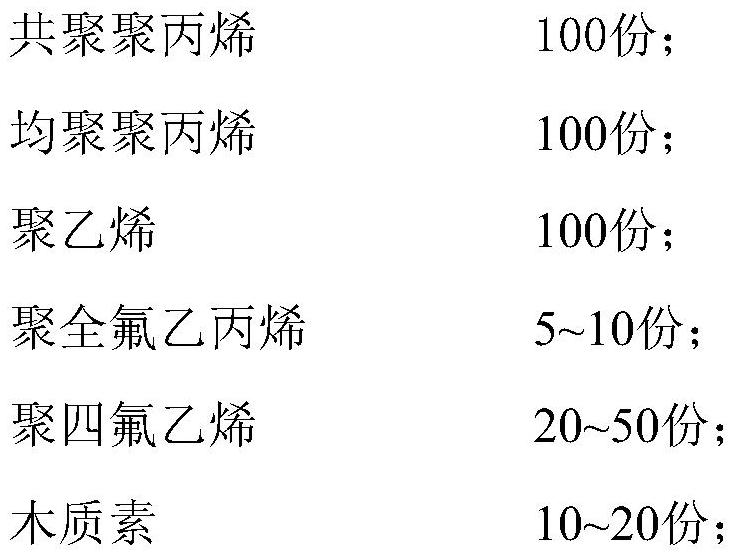

[0053] A preparation method of a low-temperature impact-resistant stress-resistant whitening polypropylene material adopts the following formula:

[0054]

[0055] The preparation steps are as follows:

[0056] (1) Mix polyperfluoroethylene propylene and polytetrafluoroethylene in a mixer for 3 minutes according to the formula ratio to obtain mixture A;

[0057] (2) According to the formulation ratio, the copolymerized polypropylene, homopolypropylene, polyethylene and lignin were mixed in a mixer for 3 minutes to obtain a mixture B;

[0058] (3) Add mixture A from the first barrel of the twin-screw extruder, feed mixture B from the sixth section of the twin-screw extruder, and carry out extrusion granulation to obtain low-temperature impact-resistant stress-resistant White polypropylene material; wherein, the speed of the twin-screw extruder is 550r / min, and the temperatures of the first section of the cylinder to the sixth section of the cylinder are 300°C, 300°C, 310°C,...

Embodiment 3

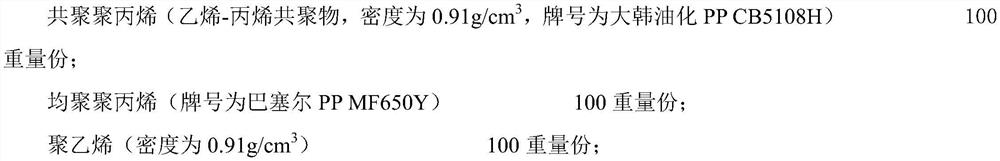

[0061] A preparation method of a low-temperature impact-resistant stress-resistant whitening polypropylene material adopts the following formula:

[0062]

[0063]

[0064] The preparation steps are as follows:

[0065] (1) Mix polyperfluoroethylene propylene and polytetrafluoroethylene in a mixer for 5 minutes according to the formula ratio to obtain mixture A;

[0066] (2) According to the formula ratio, the copolymerized polypropylene, homopolypropylene, polyethylene and lignin were mixed in a mixer for 5 minutes to obtain a mixture B;

[0067] (3) Add mixture A from the first barrel of the twin-screw extruder, feed mixture B from the sixth section of the twin-screw extruder, and carry out extrusion granulation to obtain low-temperature impact-resistant stress-resistant White polypropylene material; wherein, the speed of the twin-screw extruder is 600r / min, and the temperatures of the first section of the cylinder to the sixth section of the cylinder are 290°C, 300°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Notched impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com