Control method of excellent hot-rolled oriented silicon steel plate shape

A control method and technology for oriented silicon, which are applied in the rolling mill control device, metal rolling, temperature control and other directions, can solve the problems of unexplained influence, etc., and achieve the temperature of the cross section is basically uniform, the heating is sufficient and uniform, and the shape of the plate is excellent. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

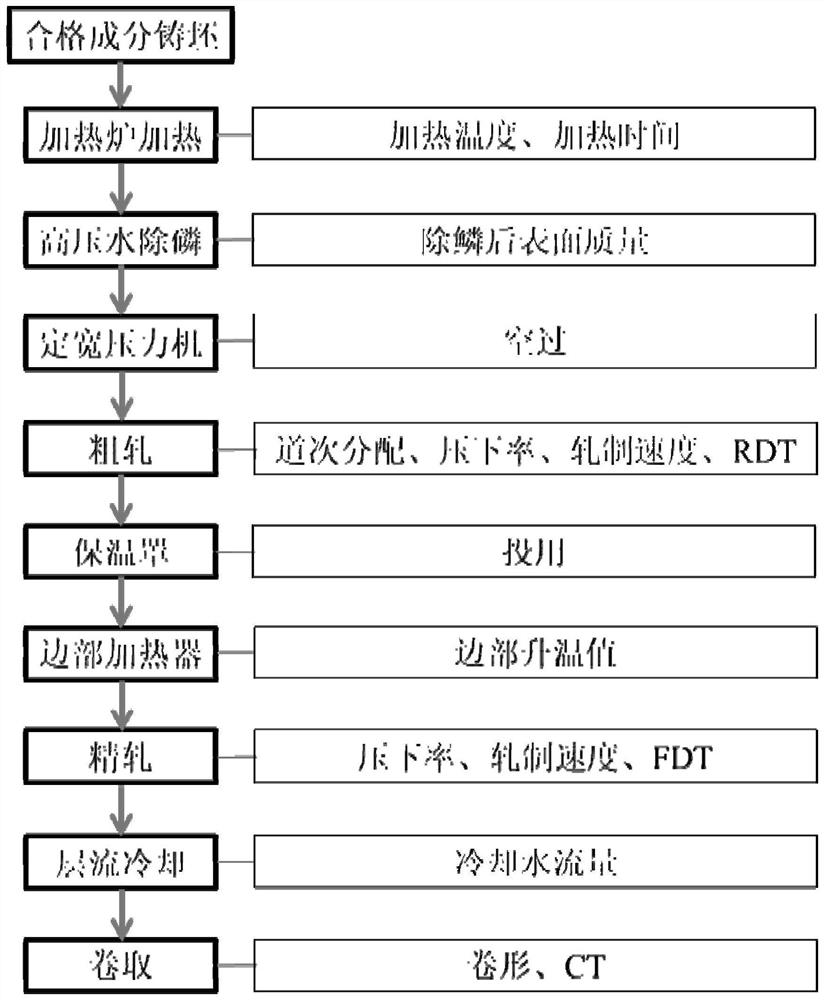

[0039] A method for controlling the shape of an excellent hot-rolled grain-oriented silicon steel sheet in this embodiment, the process is as follows:

[0040] The slabs with qualified components are heated by heating furnace, descaled by high-pressure water, emptied through fixed-width press, rough rolled, put into use by heat preservation cover and side heater, cut head and tail, finish rolling, laminar cooling and crimping process After the process, a hot-rolled grain-oriented silicon steel sheet is obtained.

[0041] Specifically, in this embodiment, the temperature of the slab before entering the heating furnace is 360°C, the temperature of the soaking section of the heating furnace in the S1 stage is 1320°C, and the soaking time is 62 minutes to ensure that the slab is heated sufficiently and evenly, and the temperature difference of each part of the slab is 5°C when it comes out of the furnace. ; After descaling with high-pressure water and emptying the fixed-width pres...

Embodiment 2

[0046] The method for controlling the shape of an excellent hot-rolled oriented silicon steel sheet in this embodiment is basically the same as that in Embodiment 1, except that in this embodiment: the temperature of the slab before entering the heating furnace is 350°C; the soaking section of the heating furnace in the S1 stage The temperature is 1280°C, and the soaking time is 60 minutes;

[0047] S2 rough rolling stage: 1 pass on E1 / R1, 3 passes on E2 / R2, the thickness reduction rate of the first pass of R1 is 42%, and the thickness reduction of the third pass of R2 The rate is 15%. After E2 / R2 is completed, the thickness of the intermediate billet is 35mm, and the temperature is 1142°C; after the intermediate billet passes through the heat preservation cover, the edge heater is used to increase the edge temperature of the intermediate billet by 40°C, and then enters the finish rolling stage;

[0048] In the S3 finish rolling stage, the F1 reduction rate is 50%, the F2 redu...

Embodiment 3

[0051] A method for controlling the shape of an excellent hot-rolled grain-oriented silicon steel sheet in this embodiment is basically the same as in Embodiment 1, except that in this embodiment:

[0052] The temperature of the soaking section of the heating furnace in the S1 stage is 1250°C, the soaking time is 65 minutes, and the temperature difference of each part of the slab is 4°C when it is released from the furnace;

[0053] In the rough rolling stage of S2, E1 / R1 is used for empty pass, and E2 / R2 is used for 5 passes, wherein the thickness reduction rate of the first pass of R2 is 37%, and the thickness reduction rate of the fifth pass of R2 is 15%. After E2 / R2 is completed, the thickness of the intermediate billet is 40mm, and the temperature is 1120°C;

[0054] The key temperature parameters of the hot-rolled grain-oriented silicon steel sheet produced by the above-mentioned preparation method meet the standards and the plate shape is excellent, and the downstream u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com