Vane wheel lifting appliance for wind generating set and vane wheel lifting method

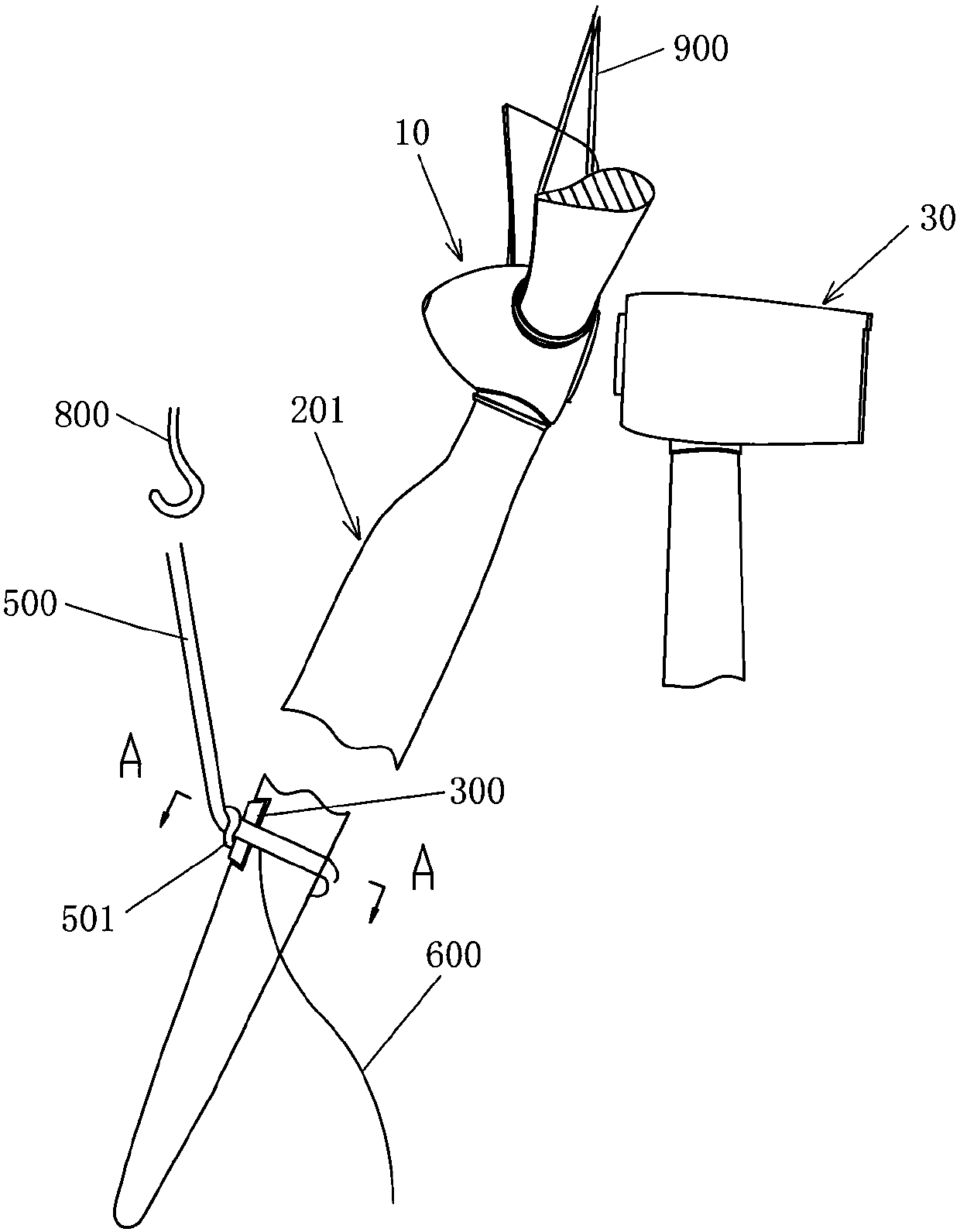

A technology for a wind turbine generator set and a hoisting method, which is applied to wind turbines, wind energy power generation, and wind turbines that are consistent with the wind direction, etc., can solve problems such as difficulty in dismantling and loosening 501 of the sling knot, the large trailing edge 201, and affecting the hoisting of the impeller. , to achieve the effect of improving safety, stability and reliability, improving stability and reliability, and convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Embodiments of the invention will now be described more fully with reference to the accompanying drawings, in which exemplary embodiments of the invention are shown.

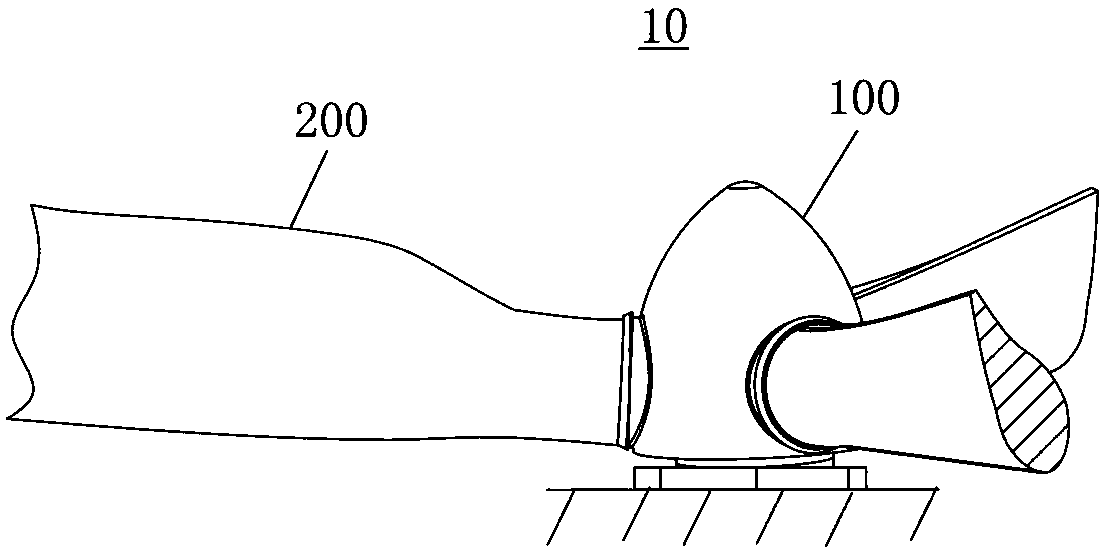

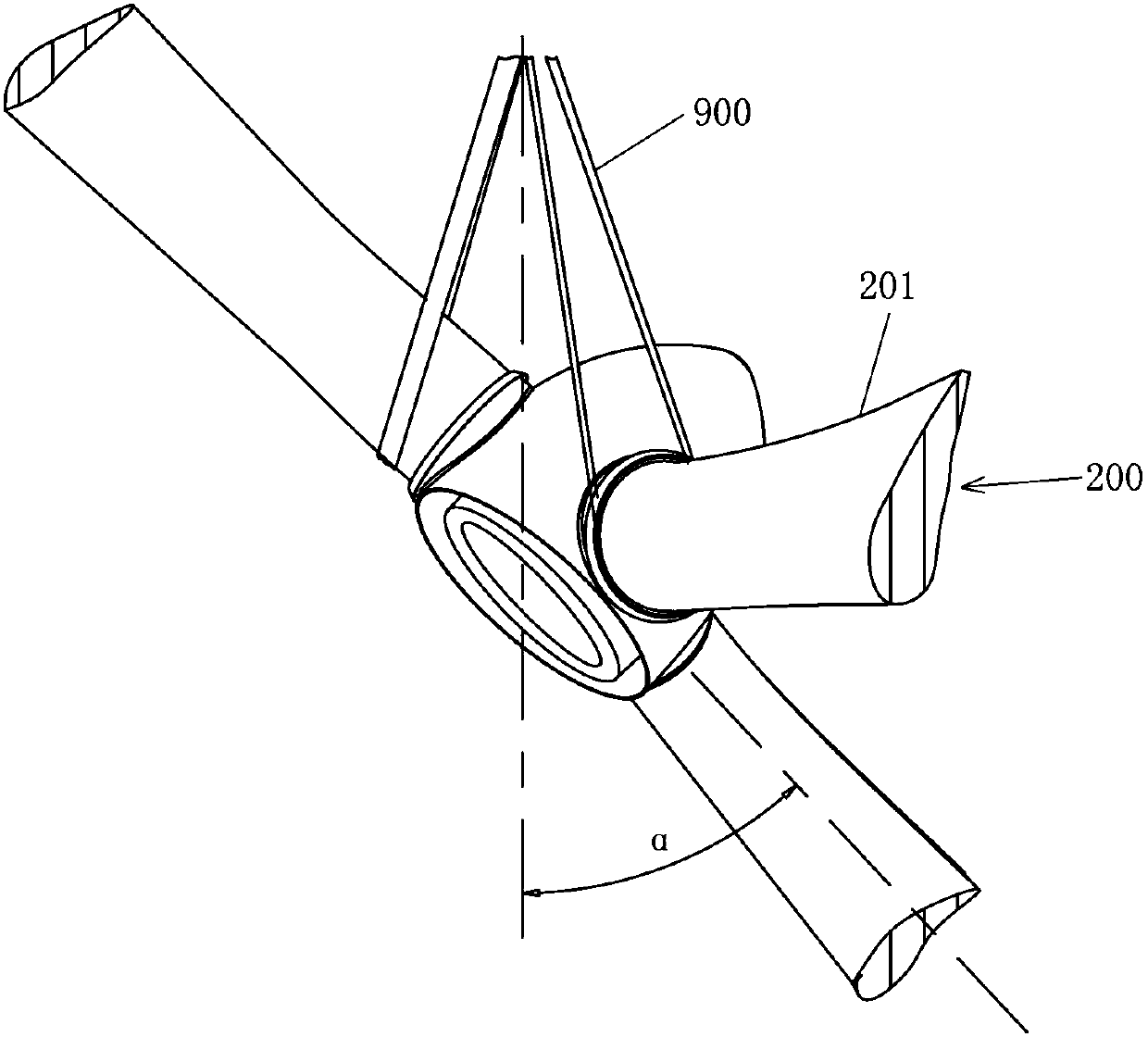

[0052] The following will combine Figure 9 to Figure 16 The impeller hanger 20 according to the exemplary embodiment of the present invention is described. Figure 9 is a left view of the wind turbine rotor hanger according to an exemplary embodiment of the present invention; Figure 10 is a front view of a rotor hanger for a wind power generating set according to an exemplary embodiment of the present invention; Figure 11 is a right side view of the wind turbine hanger of the wind power generating set according to the exemplary embodiment of the present invention; Figure 12 yes Figure 11 Enlarged view of part I shown in ; Figure 13 yes Figure 11 Enlarged view of Part II shown in ; Figure 14 is an exploded perspective view of a rotor hanger of a wind power generating set according to an exemp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com