Slave plate structure for lorry coupler buffering device

A railway wagon and plate structure technology, which is applied to railway car body components, traction devices, transportation and packaging, etc., can solve the problems of coupler frame fatigue fracture, high cost, train separation accidents, etc., and reduce maintenance labor costs and costs Low, the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

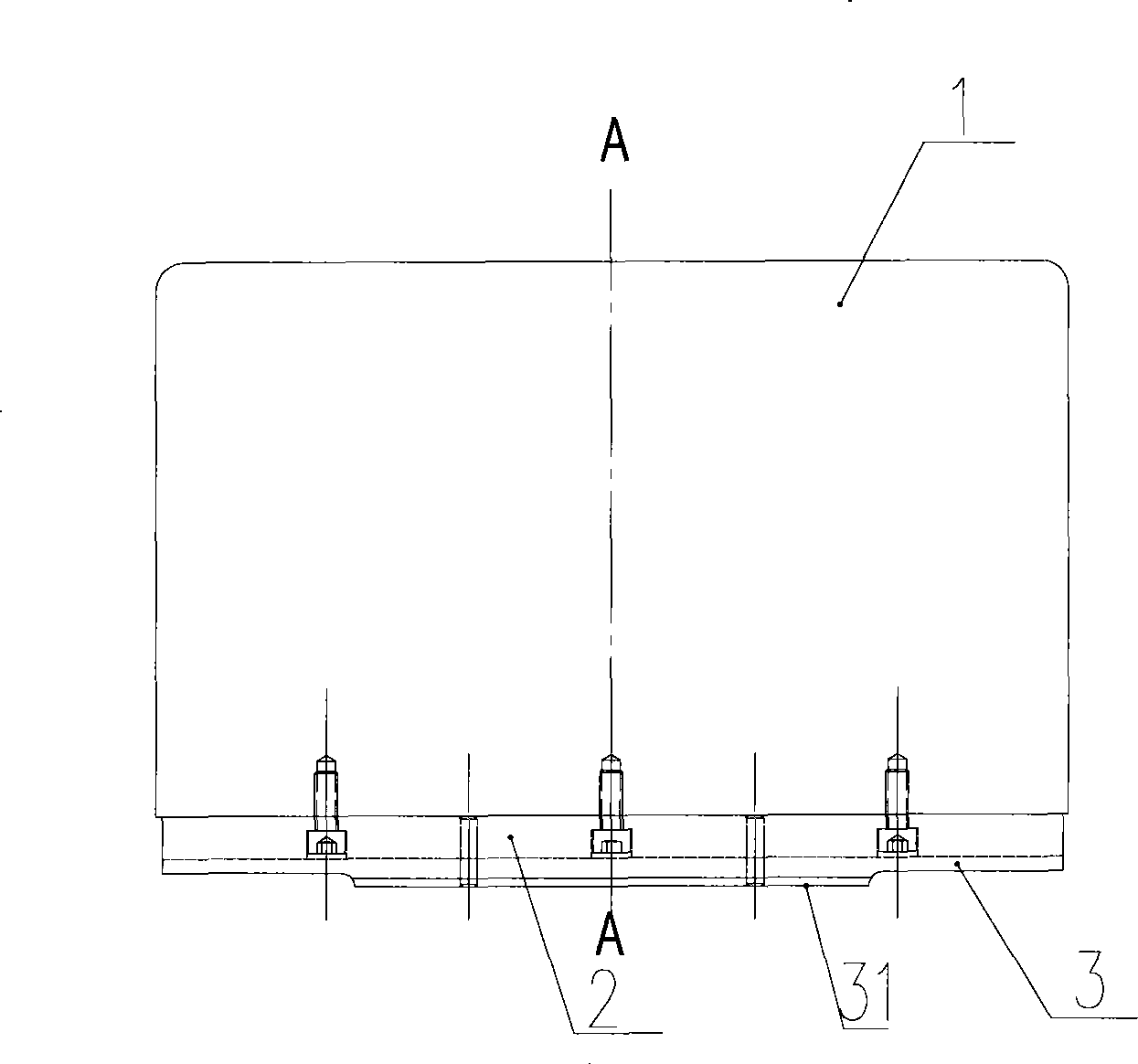

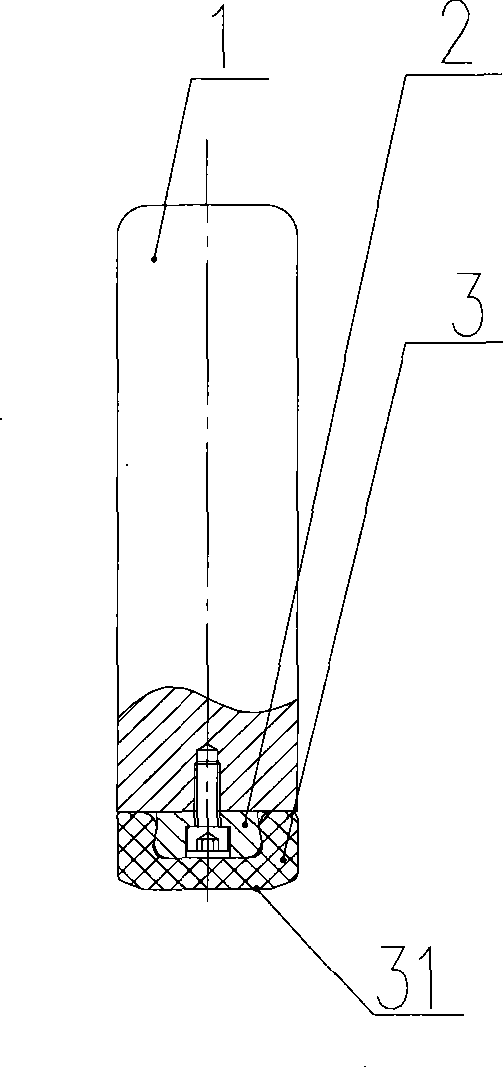

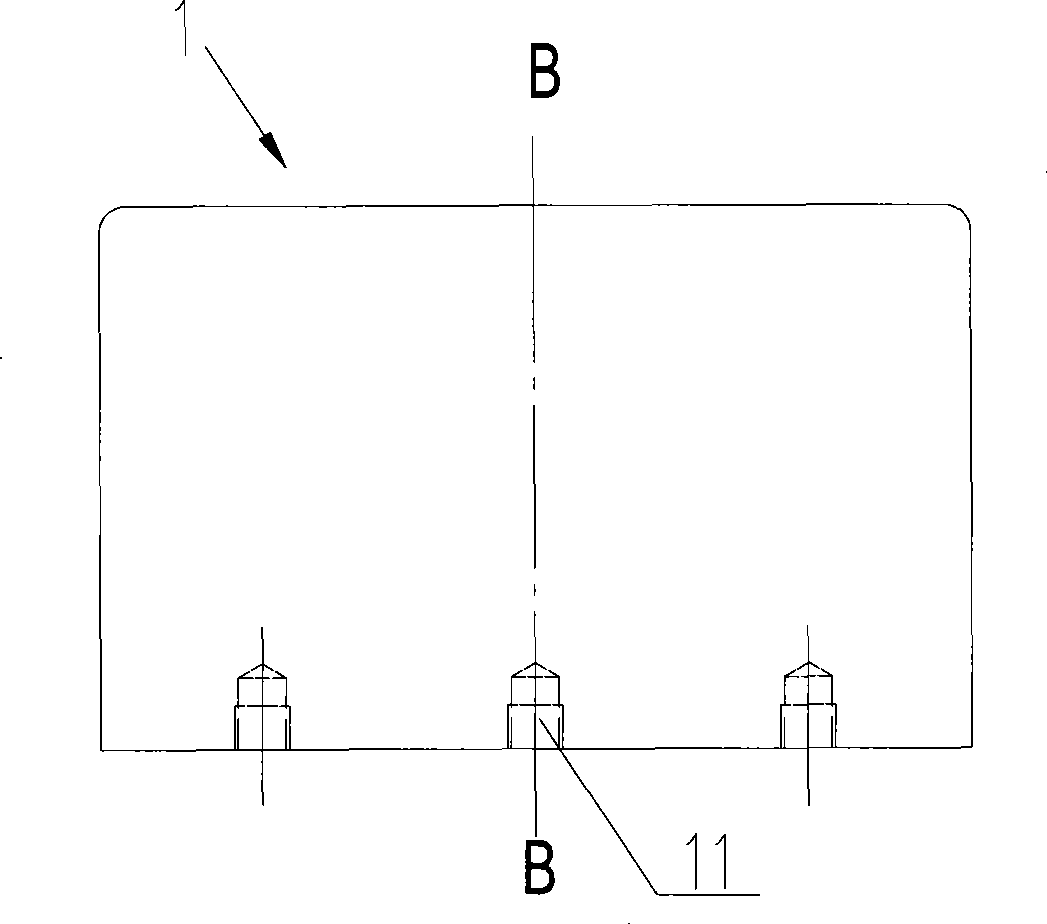

[0034] The basic idea of the present invention is to add wear plates on the slave plate body, thereby reducing wear on the coupler frame.

[0035] In the present invention, the secondary plate body bears impact force during use. To ensure strength, the secondary plate body is made of Q275 material; in order to reduce wear on the coupler frame, a non-metallic wear plate is added at the contact position between the secondary plate body and the coupler frame. Among them, the wear plate is made of non-metallic material, which should have a suitable coefficient of friction:

[0036] In view of the characteristics of low friction coefficient, high and low temperature performance and high impact resistance of oily nylon, combined with the experience of using large quantities of oily nylon center disk wear discs and side bearing wear plates on railway wagons, the wear plate is made of oily nylon or other materials with the same characteristics. Manufactured from non-metallic materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com