No-destructive testing method and no-destructive testing device for creep cavity damage of igh chromium martensitic heat-resistant steel joint

A non-destructive testing and martensitic technology, which is applied to measuring devices, processing detection response signals, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve problems such as inability to realize timely early warning and difficulty in finding creep holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below by embodiment, in conjunction with accompanying drawing, the technical scheme of the present invention is described further specifically,

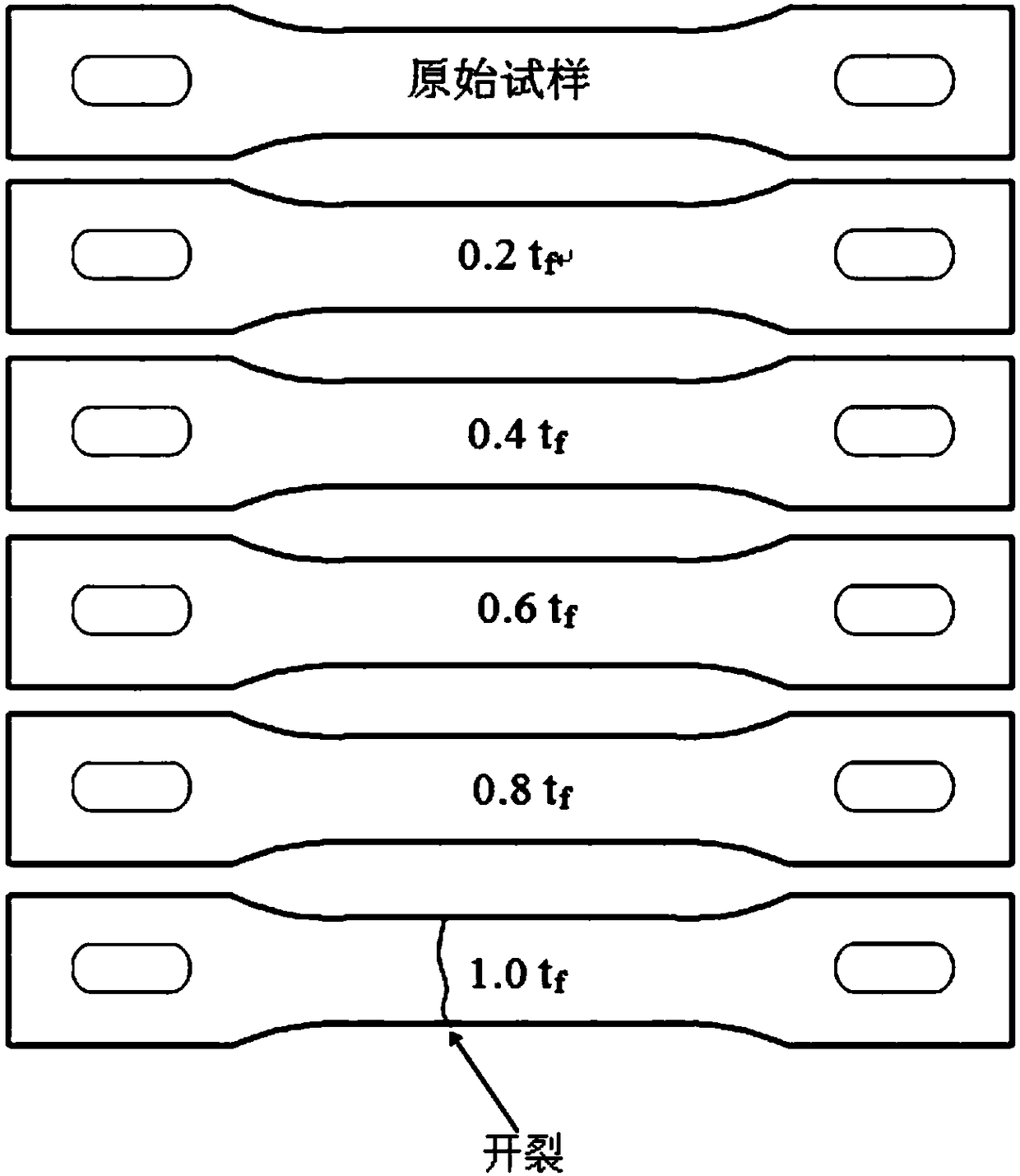

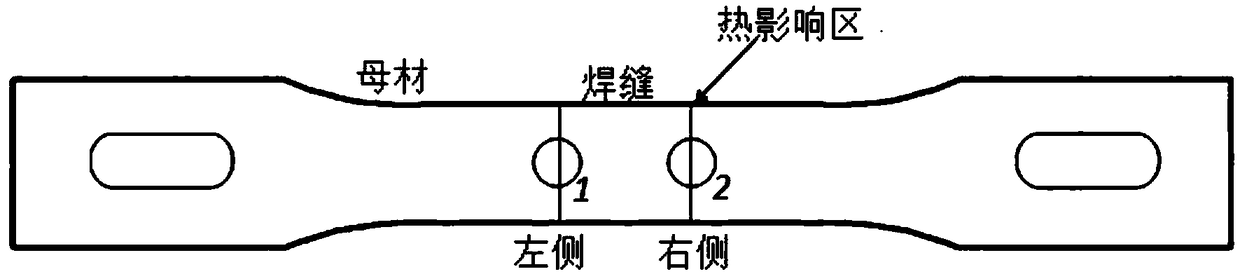

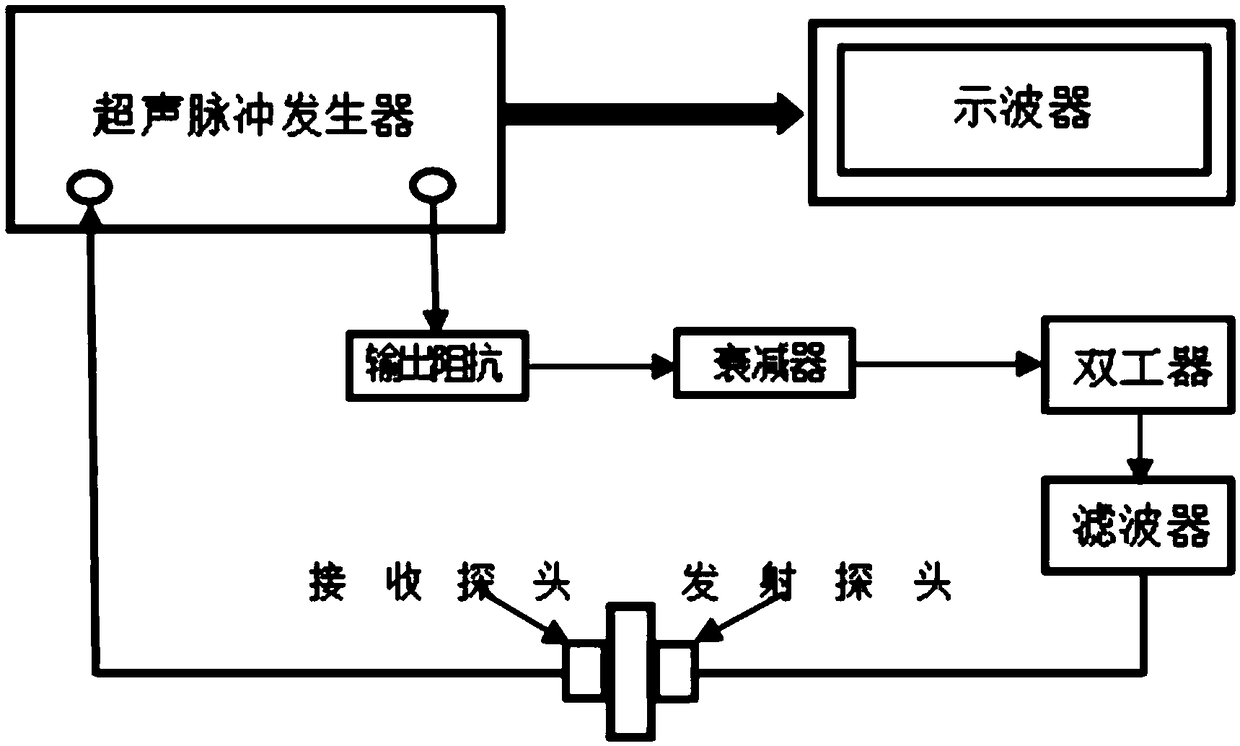

[0041] The invention provides a novel non-destructive detection method for creep hole damage of joints of high-chromium martensitic heat-resistant steel, which solves the problem that the existing non-destructive detection method cannot detect. The present invention solves the detection problem of creep hole damage of new high-chromium martensitic heat-resistant steel joints by adopting nonlinear ultrasonic technology. The principle is to use high-order harmonics generated by the interaction between high-energy radio frequency pulses and internal micro-defects , to assess the degree of damage to the joint. The invention uses nonlinear ultrasonic technology to detect the degree of high-temperature creep damage of high-chromium martensitic heat-resistant steel joints, and establishes the quantitative relationship between creep h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com