Low-temperature emergency shutoff valve of novel spring air cylinder separation structure

A spring cylinder, separate technology, applied in the field of low-temperature emergency shut-off valve structure, can solve the problem of inability to realize emergency shut-off, and achieve the effects of weight reduction, improved sealing, and height reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

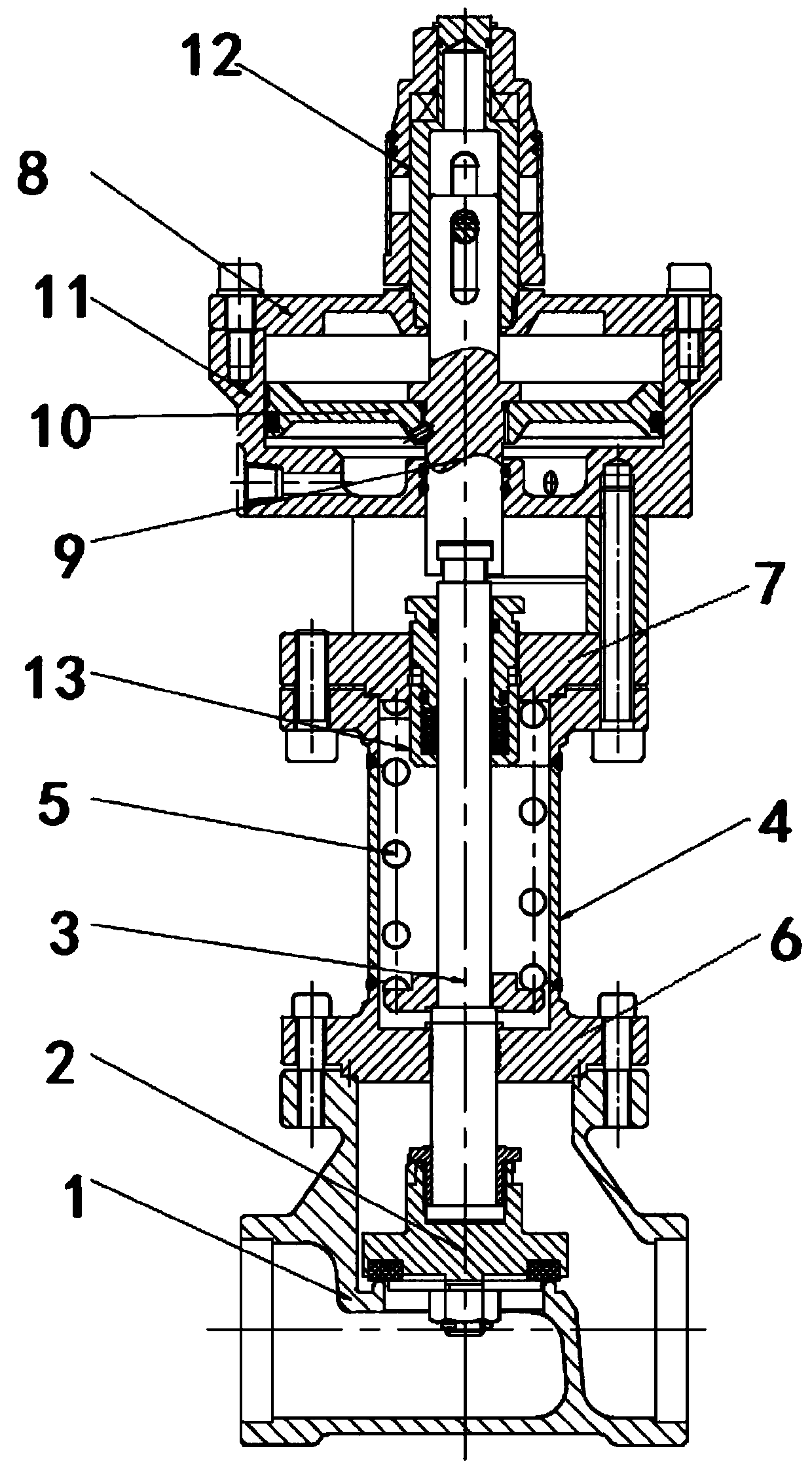

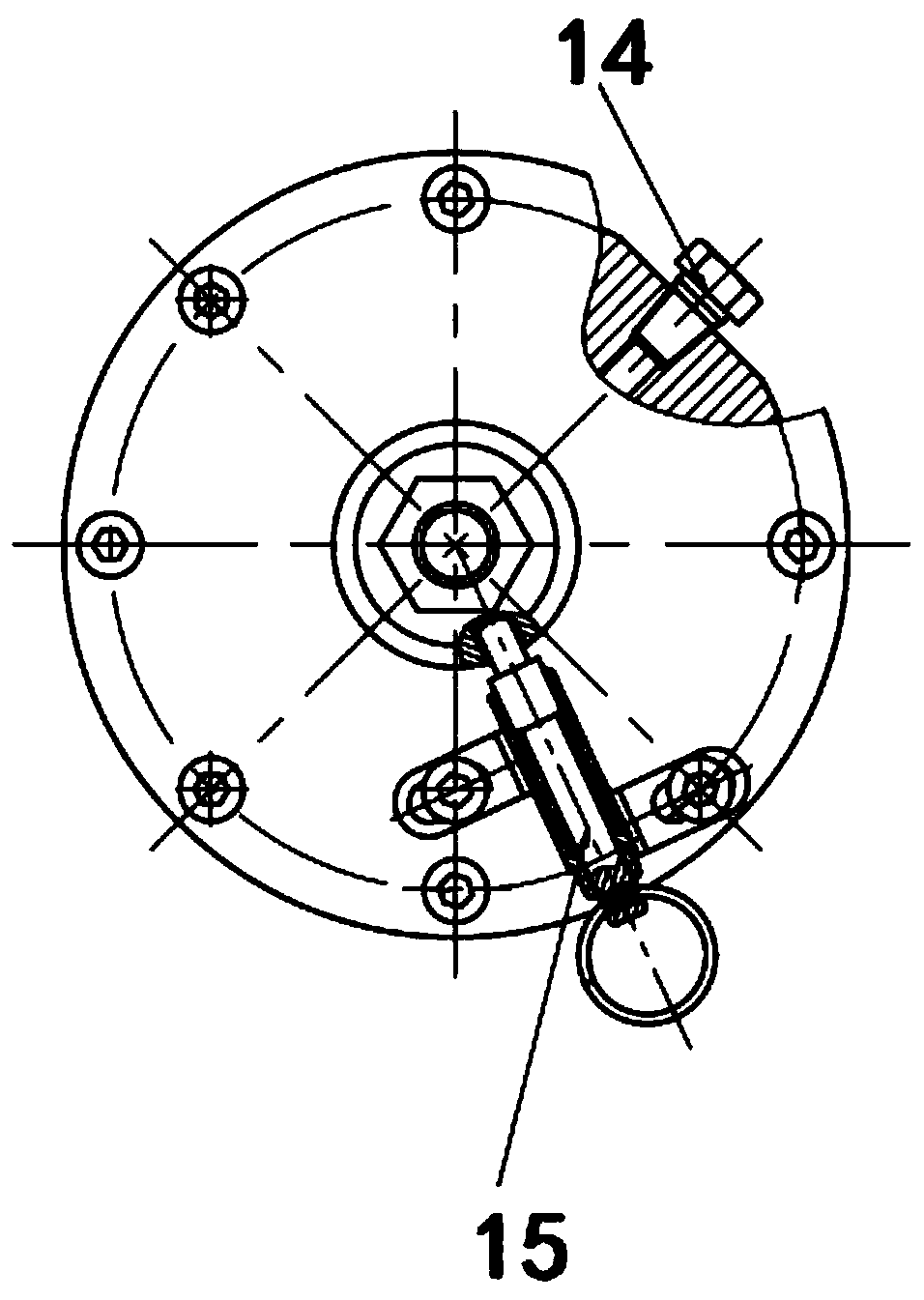

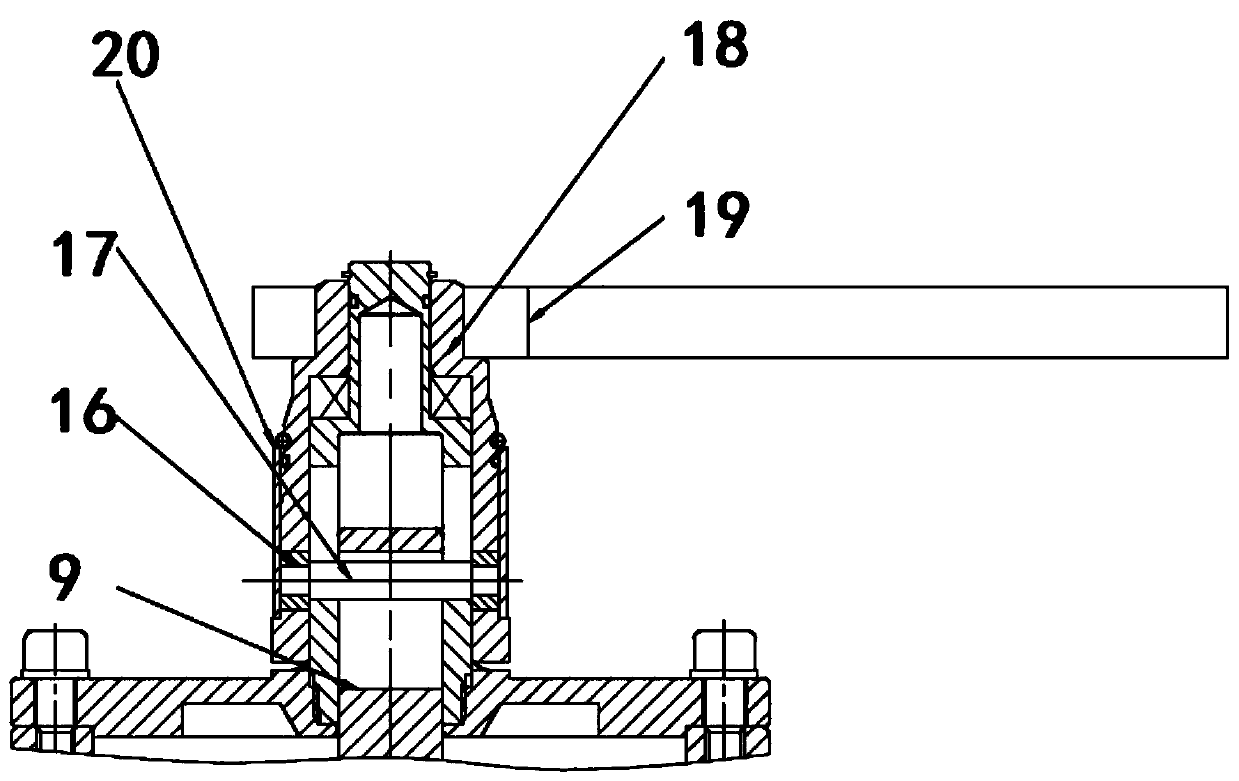

[0038] Such as Figure 1-Figure 5 As shown, a new low temperature emergency shut-off valve with separate spring and cylinder structure includes a valve body 1, the valve body includes a valve cover 6, an upper cover 7 and a cylinder head 8, a valve disc 2 is arranged in the valve body, and the valve disc and the valve stem 3 connection, a connecting pipe 4 is provided on the outside of the valve stem, and a spring 5 is set between the connecting pipe and the valve stem. Between the covers; the connecting rod is fixed to the piston 10, the piston is connected to the cylinder block 11, the cylinder block is located on the outside of the piston, and the cylinder block and the cylinder head are connected by screws; the valve body also includes a manual device 12, and the manual device includes guide wheels 16 , fixed pin 17, spiral groove body 18 and handle 19, connecting rod is connected with fixed pin, and handle is fixedly connected with spiral groove body, and guide wheel and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com