System and method for intelligently monitoring belt-type conveyer for coal mine steel wire rope core

An intelligent monitoring system, belt conveyor technology, applied in conveyor control devices, conveyor objects, transportation and packaging, etc., can solve problems such as equipment damage, casualties, and poor real-time performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

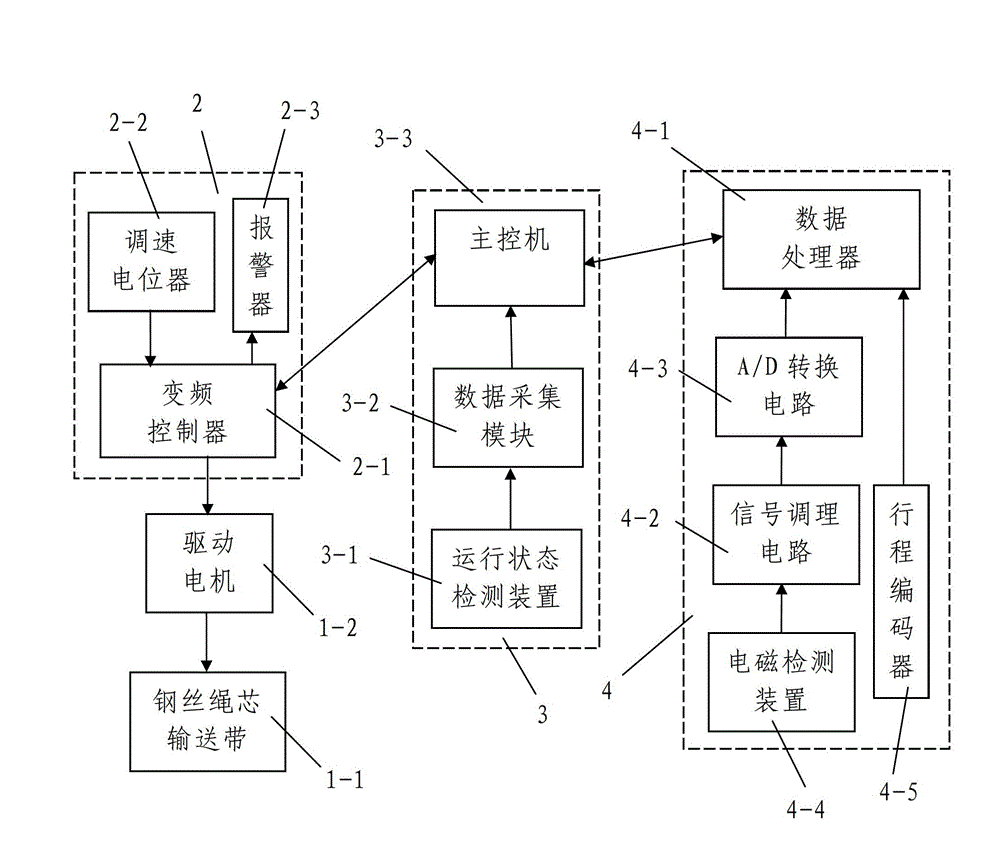

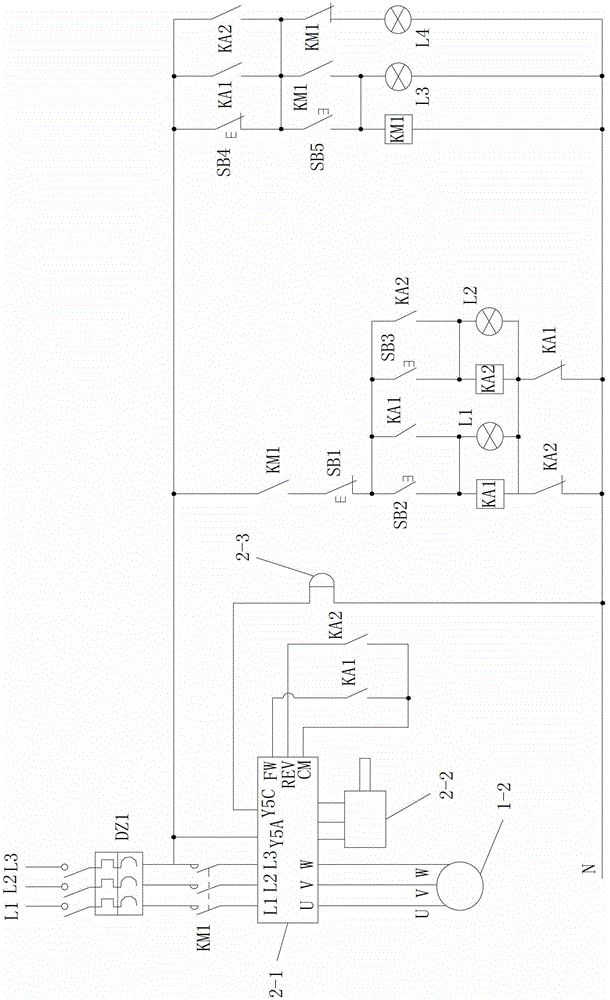

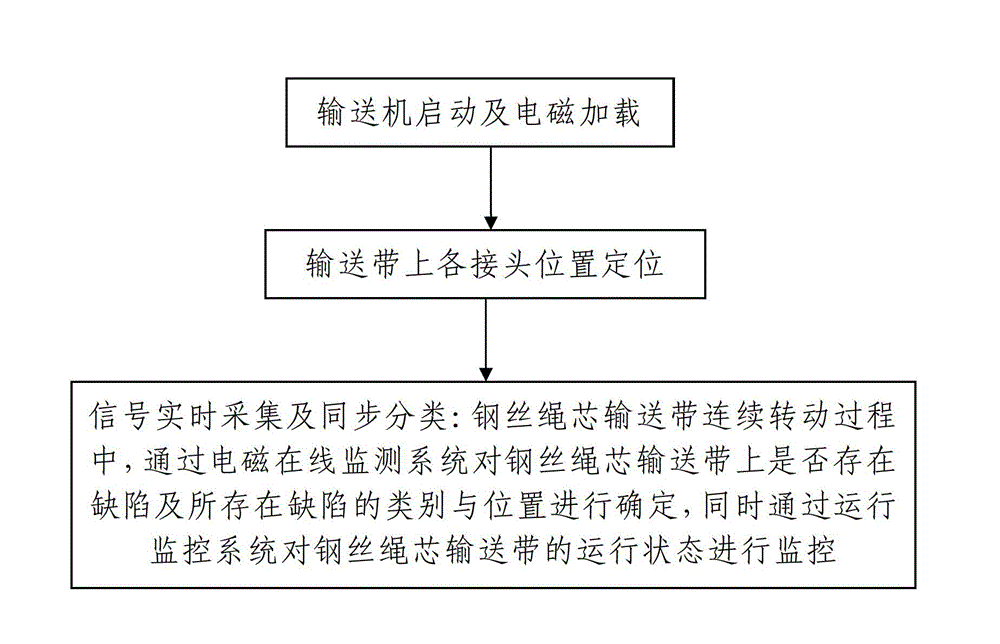

[0085] Such as figure 1 An intelligent monitoring system for a coal mine steel cord belt conveyor is shown, including a frequency conversion control system for driving and controlling the monitored steel cord belt conveyor 2. The steel cord conveyor belt installed on the monitored steel cord belt conveyor The operation monitoring system 3 for monitoring the running state of 1-1 and the electromagnetic online monitoring system 4 for real-time monitoring of whether there are defects in the steel cord conveyor belt 1-1 and the type and location of the defects. The monitored steel cord belt conveyor includes a frame, a main roller and an auxiliary roller, and a driving motor 1-2 for driving the main roller, and the steel cord conveyor belt 1-1 is installed on the main roller and the auxiliary roller. Between the auxiliary rollers, the main roller is coaxially installed on the transmission shaft, and the transmission connection between the transmission shaft and the driving motor 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com