Ultrasonic flaw detection method of scraper circular chains

A circular chain and ultrasonic technology, which is applied in the direction of using ultrasonic/sonic/infrasonic waves, using sonic/ultrasonic/infrasonic waves to analyze solids, measuring devices, etc., can solve problems such as ring chain breakage accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

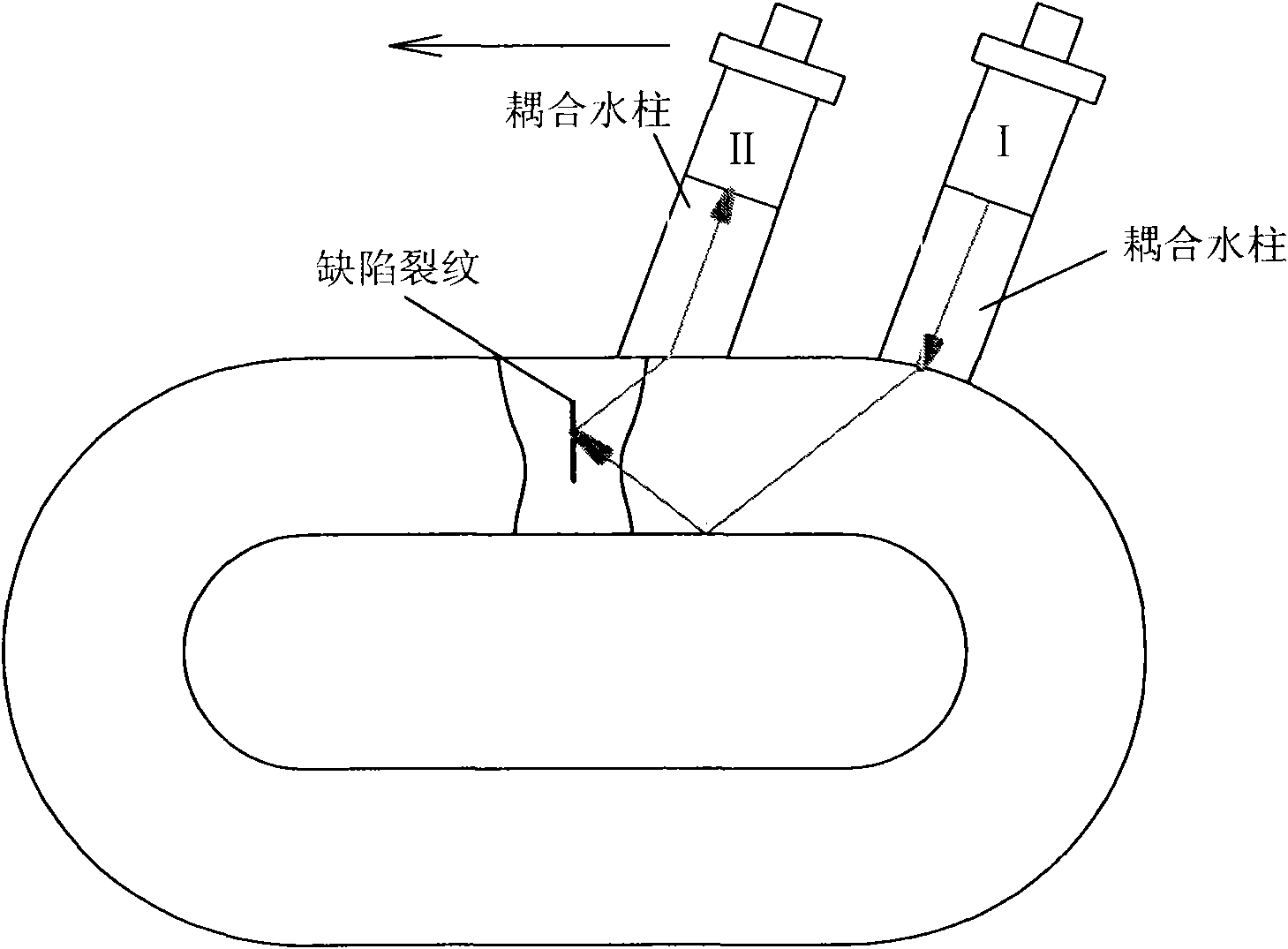

[0024] Such as figure 1 , 2 As shown, the specific steps of an ultrasonic flaw detection method for a scraper circular link chain are:

[0025] 1. Run the scraper conveyor at a low speed, the speed can be 0.3~0.5m / s;

[0026] 2. Turn on the flaw detector, turn on the water supply switch of the special probe, and supply water to the probe;

[0027] 3. Use a special probe to slide through the straight section of each circular chain with a weld in turn, and observe the echo at the specified position.

[0028] 4. According to the standard sample, determine the relationship between echo height and crack depth, and determine the echo height alarm threshold; when the observed echo height is higher than the alarm threshold, an alarm will be prompted; when When it is lower than the alarm threshold, no alarm is given, so as to realize accident prevention warning.

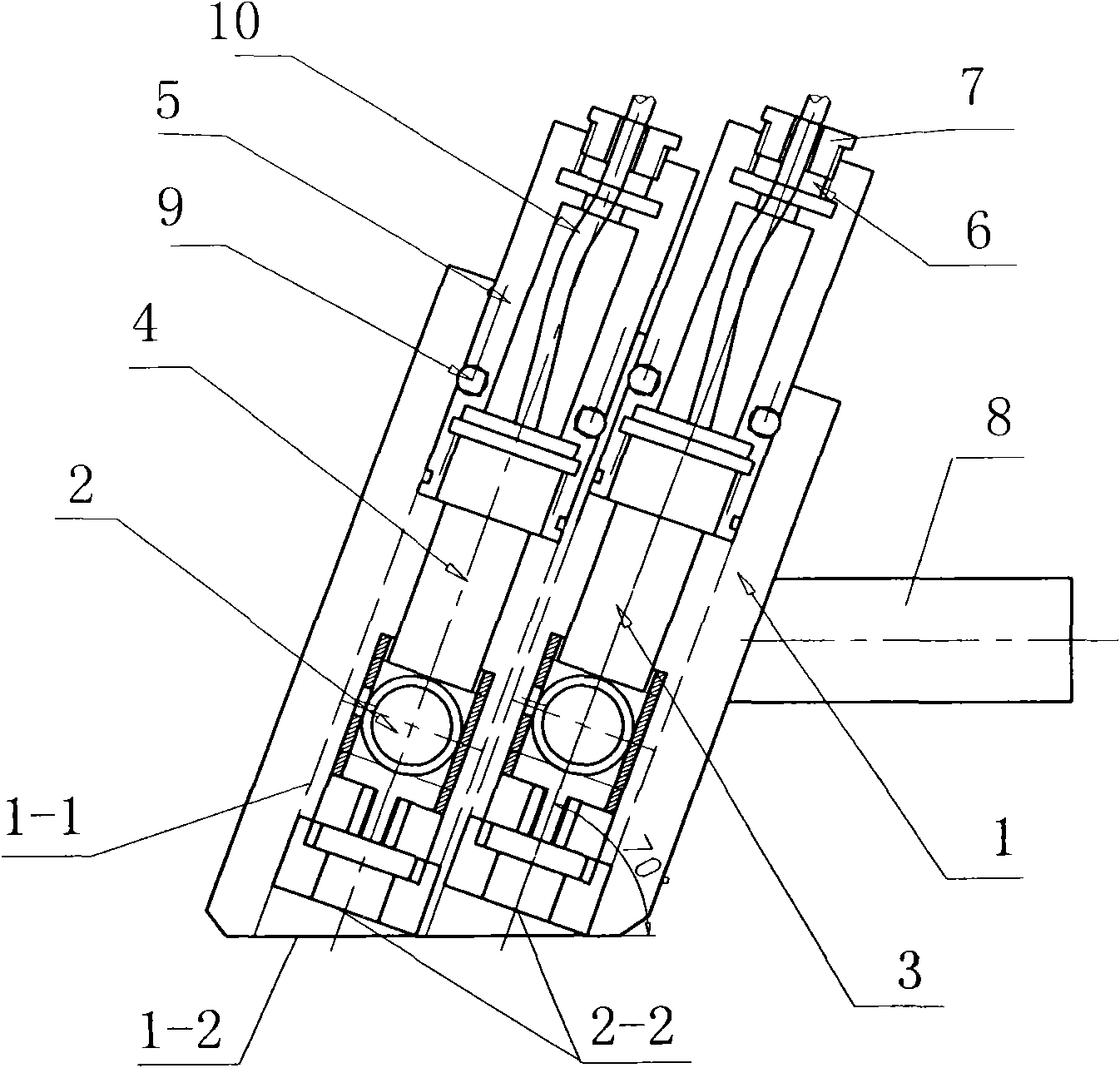

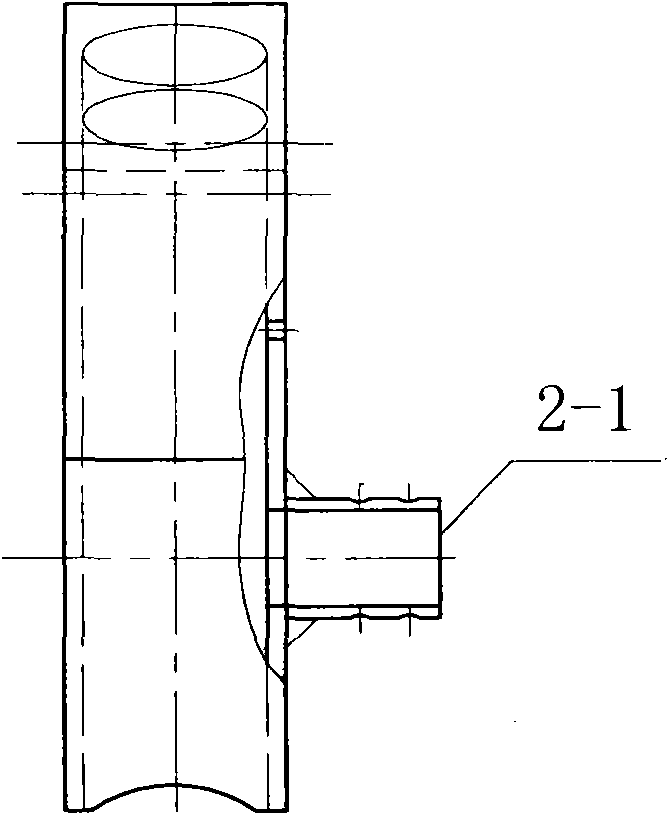

[0029] Such as figure 2 , 3 As shown in , 4, the special probe for realizing the scraper ring chain ultrasonic flaw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com