Stress measurement device and method for knob insulator

A porcelain post insulator and stress detection technology, applied in measuring devices, measuring force, instruments, etc., can solve problems such as difficult operation, complicated maintenance, and immaturity, and achieve the effects of preventing fracture accidents, high reliability, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

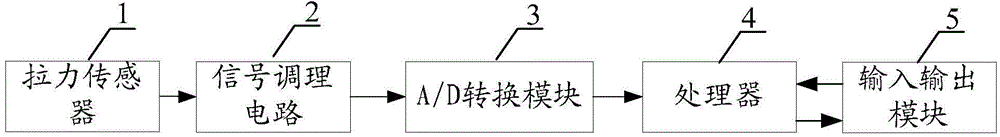

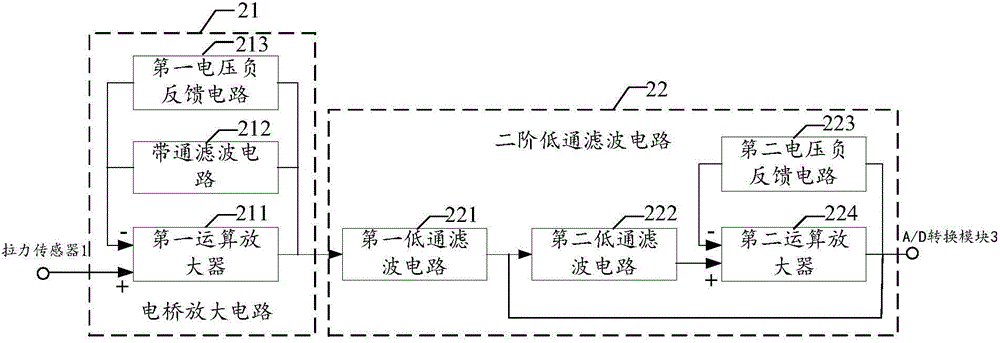

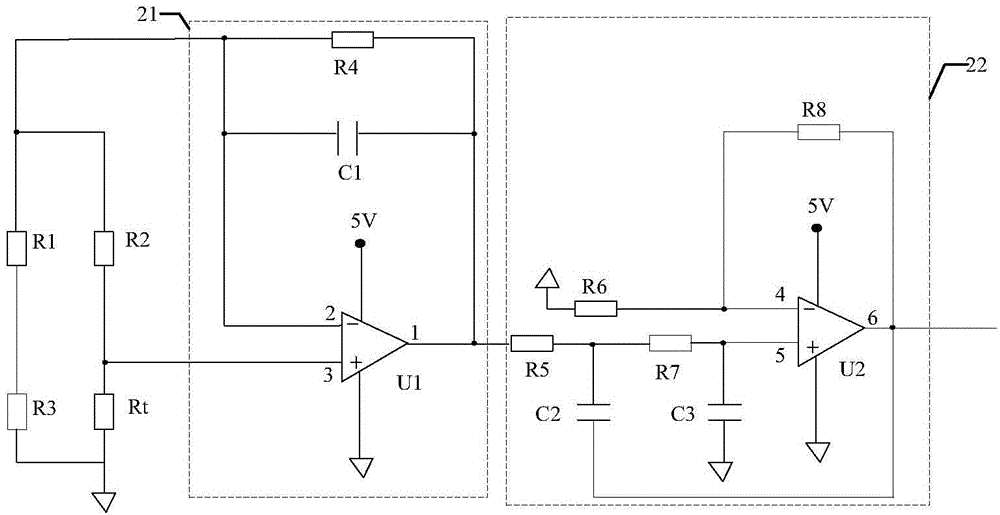

[0046] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0047] According to the statistical results of fracture accidents of porcelain post insulators, the inventor knows that the fractured parts of porcelain post insulators are concentrated at the umbrella root. Since the material of the umbrella root of the porcelain post insulator is a ceramic material, according to the microstructure of the ceramic material, it is mainly composed of ionic bonds and covalent bonds. These two chemical bonds are characterized by strong directionality and high bonding strength. It is difficult for significant dislocation movement to occur in the organizational structure, which makes the insulator show the characteristics of strong brittleness and weak plasticity at the macroscopic level. Therefore, it can basically be considered that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com