Machining method of weak-rigidity thin-wall hollow structure part

A technology for structural parts and processing methods, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as high dimensional position matching accuracy requirements, parts distortion, and parts difficult to meet design requirements, so as to avoid breakage accidents. , The effect of preventing processing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

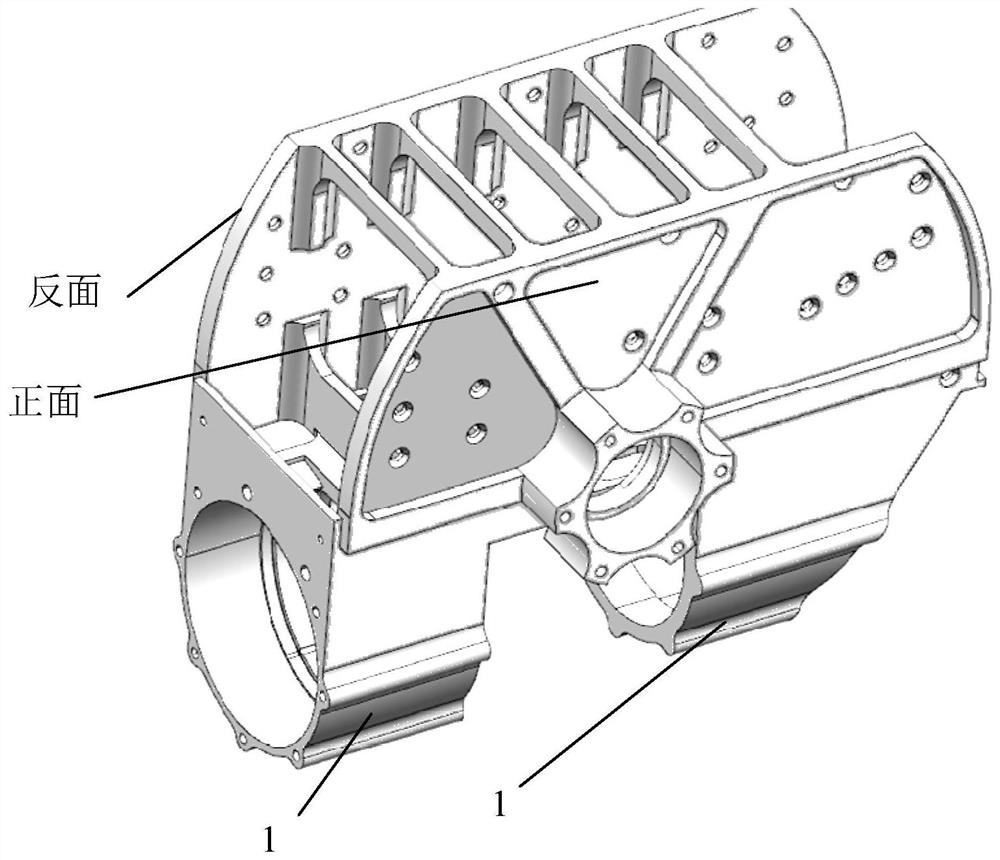

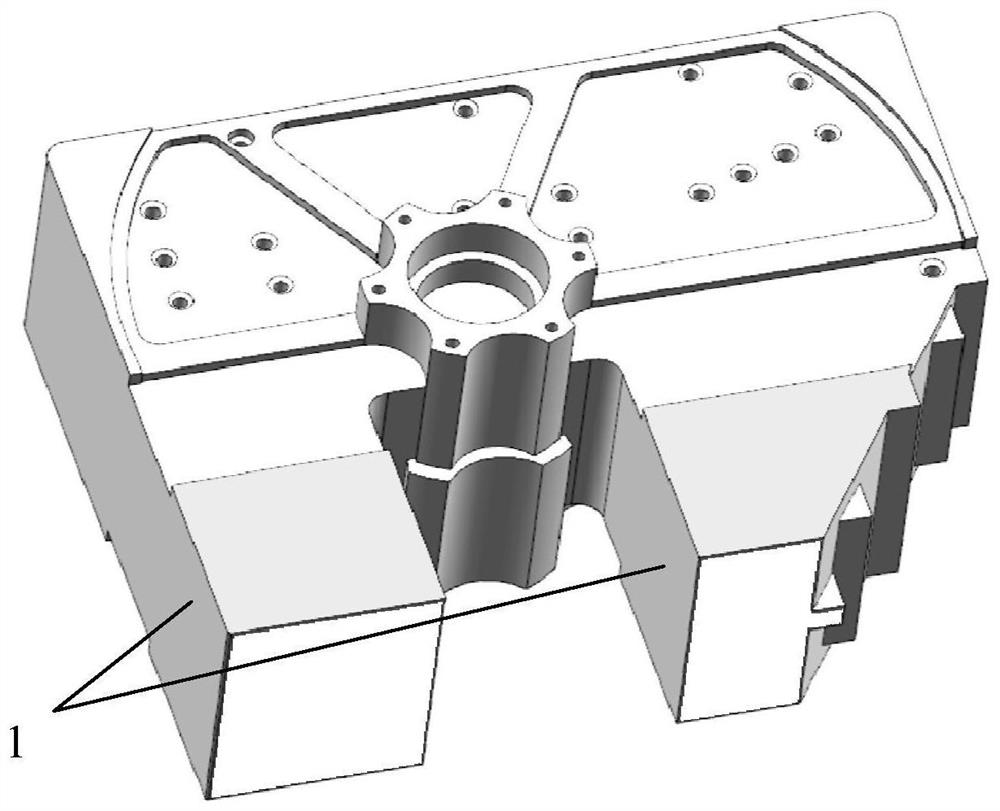

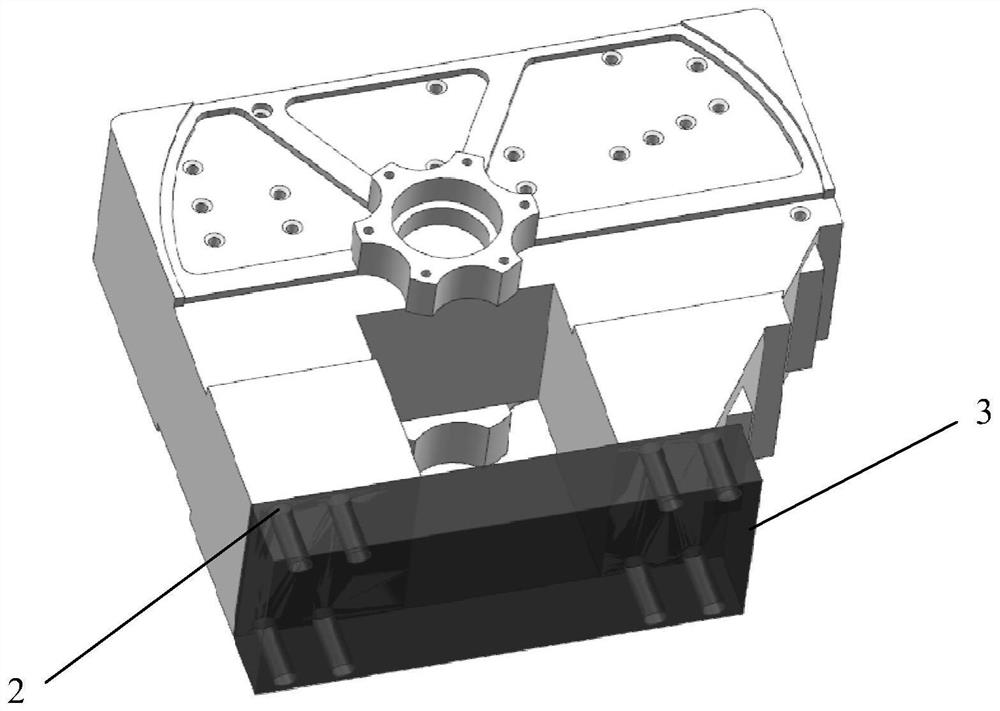

[0025] based on the following Figure 1 to Figure 5 , specifically explain the preferred embodiment of the present invention.

[0026] The rigidity of weakly rigid thin-walled structural parts is poor. Due to residual stress, clamping force, cutting force, cutting heat and other factors during processing, thin-walled structural parts are prone to processing deformation and cutting vibration, resulting in processing errors, making it difficult to Guarantee the processing accuracy and surface quality of the parts. In severe cases, the parts will be scrapped, so it cannot be processed by conventional machining methods. How to take effective measures to control or reduce the processing deformation of thin-walled parts and ensure the processing quality is an urgent problem to be solved.

[0027] The invention provides a method for processing weakly rigid thin-walled hollow structural parts, comprising the following steps:

[0028] Step S1, rough machining the front and back sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com