Machining anti-deformation clamp for thin-wall baffle part

An anti-deformation and fixture technology, used in manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve problems such as large allowances, out-of-tolerance parts, and thin walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

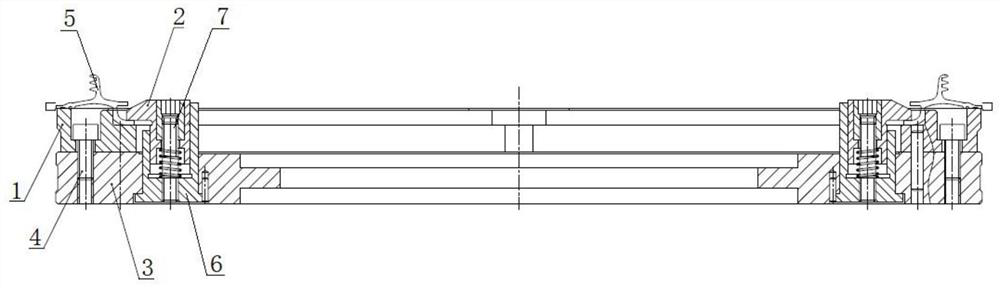

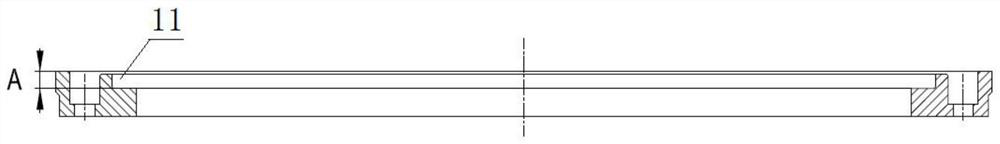

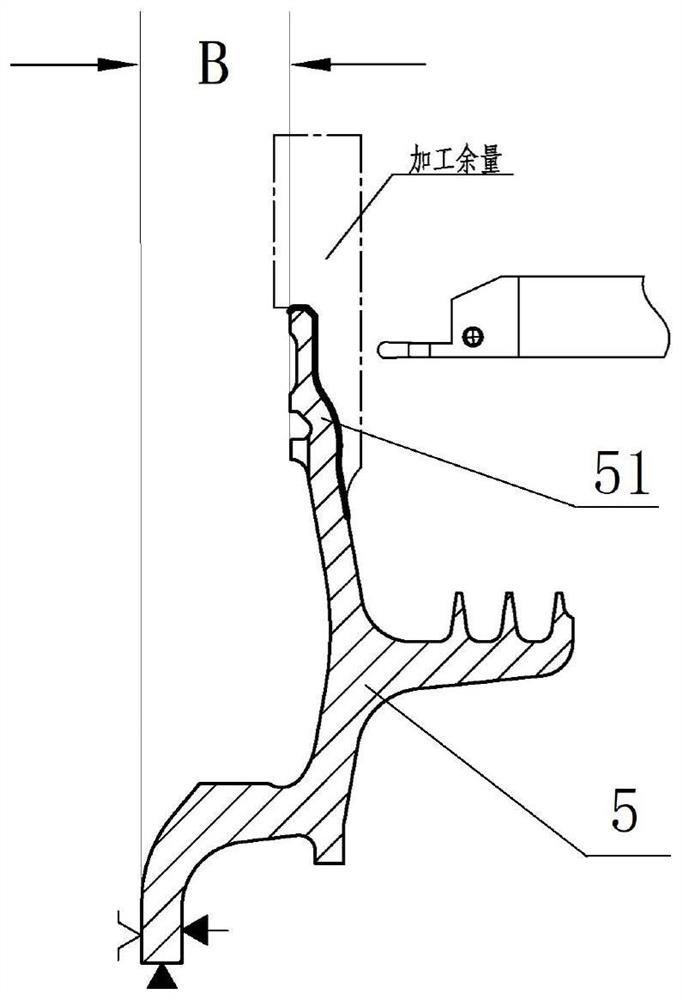

[0019] Such as Figure 1-2 As shown, a processing anti-deformation fixture for thin-walled baffle parts includes a positioning clamp body 1, a pressure hook 2, and a clamp base 3. The positioning clamp body 1 is annular and is provided with an annular step groove 11. The parts to be processed 5 Installed in the annular step groove 11, the outer step ring surface of the positioning clamp body 1 is higher than the inner step ring surface, and the back of the outer part 51 to be processed of the part 5 to be processed is tightly abutted on the outermost step surface of the positioning clamp body 1 ; The fixture base 3 is fixedly connected to the lower part of the positioning fixture body 1; the pressure hook 2 is "L" shaped, the upper end is buckled on the part 5 to be processed, and the lower end passes through the fixture base 3 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com