A processing method of metal mold with cutting edge

A metal mold and processing method technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve problems such as economic loss, unqualified workpiece quality, bumps, etc., to ensure accuracy and quality, and ensure processing accuracy. , to avoid the effect of processing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] A method for processing a metal mold with an edge, comprising the following steps:

[0035] a. Use CNC machine tools to process the contour of the mold to obtain the mold blank;

[0036] b. Fix the mold blank with a clamp, and the clamp is fixed at the edge processing position where the mold blank is to be processed into a cutting edge; at the edge processing position, the clamp matches the shape of the mold blank;

[0037] c. Machining and forming a cutting edge at the cutting edge processing position to obtain a metal mold with cutting edges.

[0038] Step c also includes: processing the remaining part of the mold except the edge.

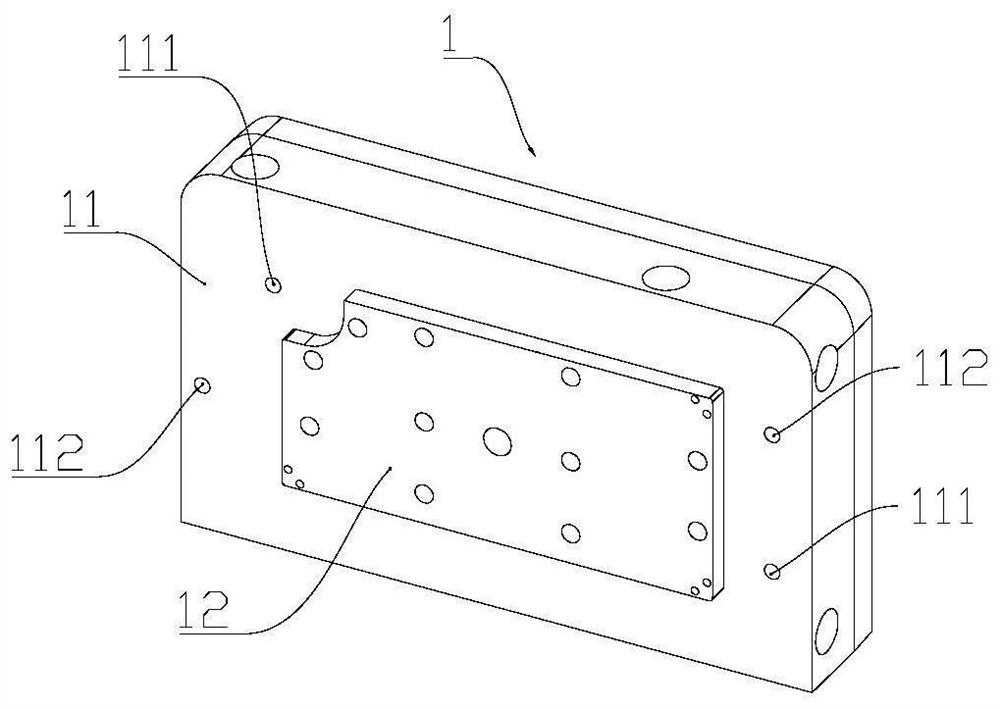

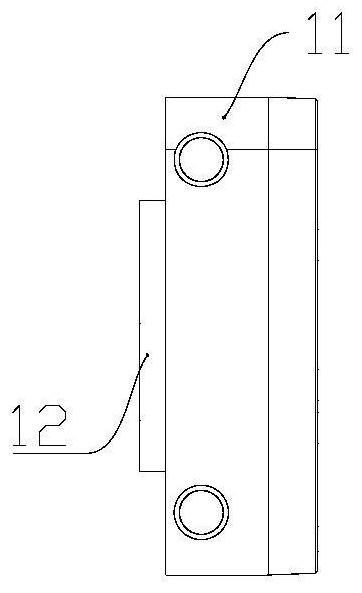

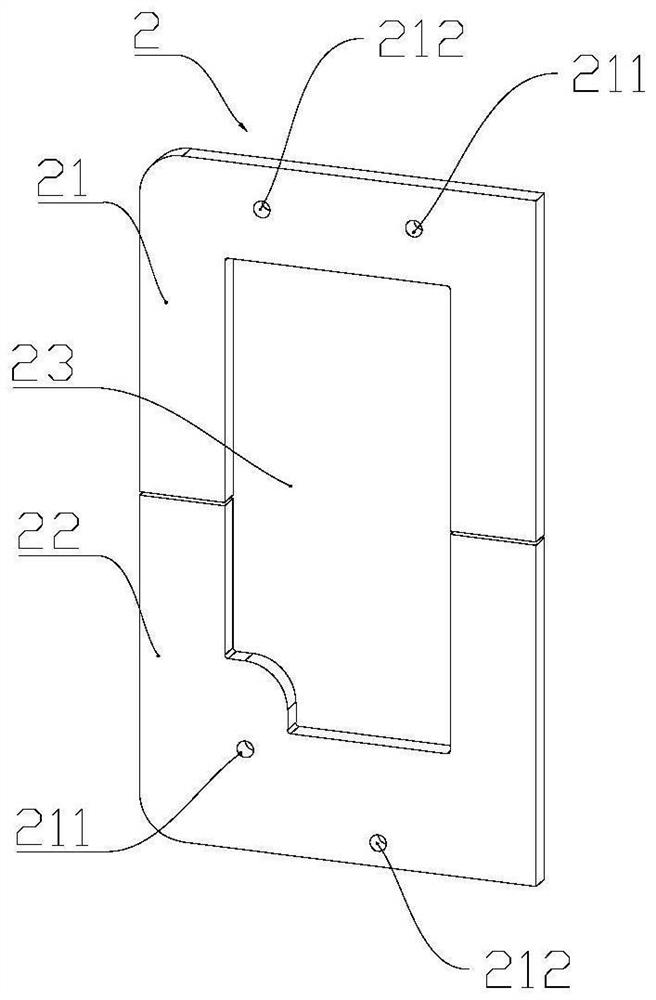

[0039] refer to figure 1 and figure 2 The mold blank 1 includes a mold body 11 and a boss 12 arranged on the mold body 11, the four sides of the boss 12 top surface need to process cutting edges 32, and the mold body 11 is also provided with a first threaded hole 111 and a second threaded hole 111. A pin hole 112. refer to image 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com