Hydraulic-driving coring tool for complex well

A hydraulic and complex technology, applied in the direction of extraction of undisturbed cores, earth-moving drilling, etc., can solve the problems of affecting the progress of coring, inability to cut pins, and long coring time, so as to improve the efficiency and quality of coring, and improve the efficiency of coring. Efficient and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

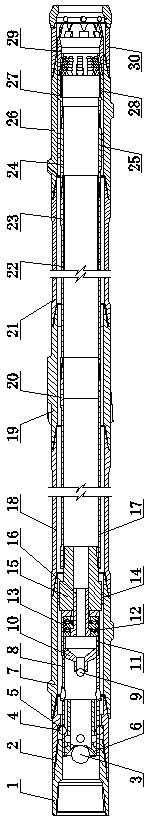

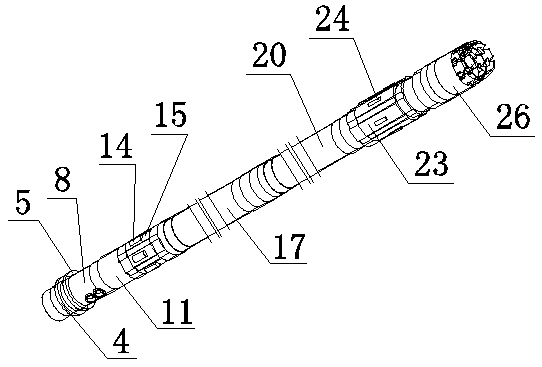

[0026] The implementation of the hydraulically driven coring tool for complex wells will be described in further detail below in conjunction with the accompanying drawings (see Figure 1-7 ):

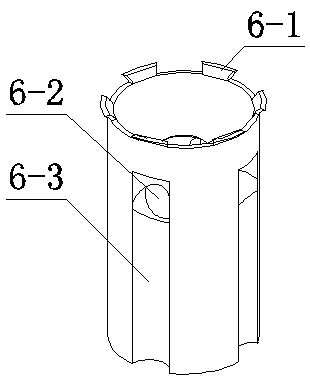

[0027]A hydraulically driven coring tool for complex wells, which consists of a bearing shaft 8, a back pressure ball 9, a back pressure ball seat 10, a bearing seat 11, a two-way thrust ball bearing 12, a shear pin 23, a shrink The neck sleeve 27, the outer core barrel assembly, the inner core barrel assembly, the suspension assembly, the inner barrel centering mechanism, the core claw assembly and the coring bit 30 are composed; the outer core barrel assembly consists of an upper joint 1 and a safety joint in turn 2. The upper spiral centralizer 7, the first outer core barrel 18, the middle spiral centralizer 19, the second outer core barrel 21 and the lower spiral centralizer 26 are connected with male and female threads; the inner core barrel assembly It is composed of the upper sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com