High temperature drilling experiment device

An experimental device and high-temperature technology, applied in earthwork drilling, drilling equipment, drilling automatic control system, etc., can solve the problems of complex structure, lack of high-temperature drilling test device, and large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

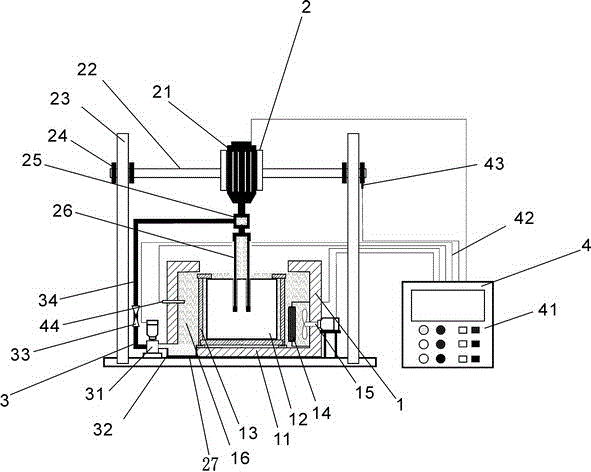

[0014] see figure 1 As shown, the present invention is composed of a high-temperature fluid chamber 1, a rotary drilling system 2, a flushing fluid circulation system 3 and a drilling control recording system 4. The high-temperature fluid chamber 1 and the flushing fluid circulation system 3 are fixedly arranged in the rotary drilling system respectively. 2, the drilling control and recording system 4 is connected to the high-temperature fluid chamber 1, the rotary drilling system 2 and the flushing fluid circulation system 3 respectively through cables 42;

[0015] The high temperature fluid warehouse 1 includes a heat preservation chamber body 11, a clamping mechanism 13, a heating element 14 and an agitator 15. The clamping mechanism 13 is fixedly arranged on the upper end of the heat preservation chamber body 11, and the heating element 14 and the agitator 15 are fixedly arranged on the heat preservation chamber body respectively. 11 right side;

[0016] The rotary drilli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com